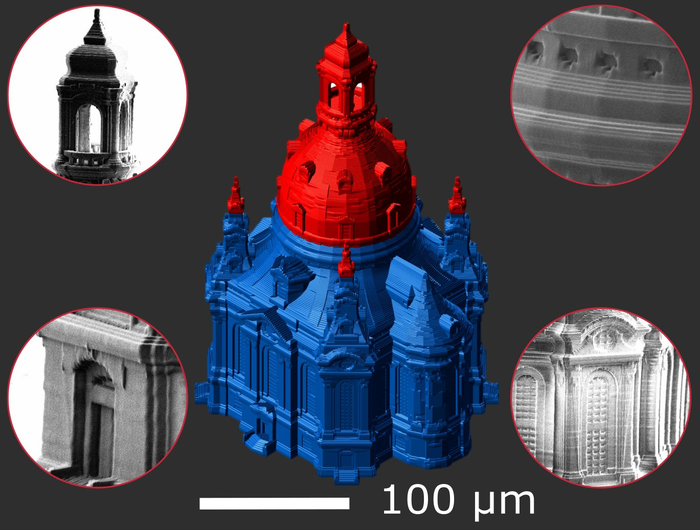

Automated multi-material 3D printing finer than a human hair: adding material exchange to 2-photon-direct laser writing lithography. (Model of the Frauenkirche Dresden with microscope images of printed details). Image Credit: Dr Robert Kirchner.

3D printing necessitates high-performance processes similar to those used in the semiconductor manufacturing of planar structures. Two-photon polymerization (2PP) is one of the quickest and highest-resolution additive manufacturing processes.

3D prints thinner than a human hair can be made with 2PP, although only from single materials thus far. This severely restricts the areas of application and potential of this leveraging technology. As of now, material exchange for prints made of multiple materials and multiple properties has had to be done manually, which is a very labor-intensive, time-consuming, and thus pricey process step.

Moreover, printing with the fresh material must resume where it left off with the previous work. This realignment precision, however, cannot be accomplished manually with structure sizes in the sub-micron range.

HETEROMERGE has devised a patented technology for automated material exchange for 2PP printer systems, enabling multi-material prints with structure scales of 100 nm and greatest print head realignment precision of up to 10 nanometers after the material change, independent of the print substrate.

The automatic machine transfer can be up to ten times better than the error-prone manual exchange. 3D printing is feasible on all prevalent microsystem printing substrates (e.g., silicon, glass), as well as passive and active structures like integrated opticals, LEDs, lasers, optocouplers, or optical fibers.

The technology serves as a “missing link” for a wide range of new application fields, particularly in the fields of micro-optics and microfluidics, as well as photonics packaging and tissue engineering, and thus enables the industrial utilization of elevated printer systems.

A research team, MESO3D - Mesoscopic 3D Systems, developed HETEROMERGE. In autumn 2021, the team led by Dr. Robert Kirchner was incorporated into the study cluster Center for Advancing Electronics Dresden (cfaed). The group has been preparing to enter the market since May 2022, thanks to funding from the German Federal Ministry of Economics and Climate.

The researchers received application advice and assistance from dresden|exists, the start-up service of Dresden’s universities and institutes. The professionals will proceed to assist the team throughout the spin-off procedure. The founding team has decades of experience in high-resolution 3D printing, fluidics, polymer chemistry, and material science, as well as start-up and hands-on experience.

HETEROMERGE is presently looking for additional team members who are excited about bringing this revolutionary technology to market. This is especially true in the areas of hardware and software design, as well as materials science and fluidics.