Several non-destructive testing (NDT) techniques based on the processing and recording of acoustic signals and the variation of electrical properties, such as electromagnetic emissions and electrical resistivity, have already been developed to understand the crack propagation processes and fracture mechanisms in mechanically-loaded structures and materials and detect the fracture region entrance.

Electrical resistivity measurements were performed in previous studies to investigate the mechanical characteristics, such as pore structure and durability, of mechanically-loaded cement-based structures and materials, specifically in their curing phase. The electrical resistance of cementitious materials increases with aging due to the intermediate pore space closure, decrease in moisture content in cement pores, and initial cracking owing to the low tensile strength.

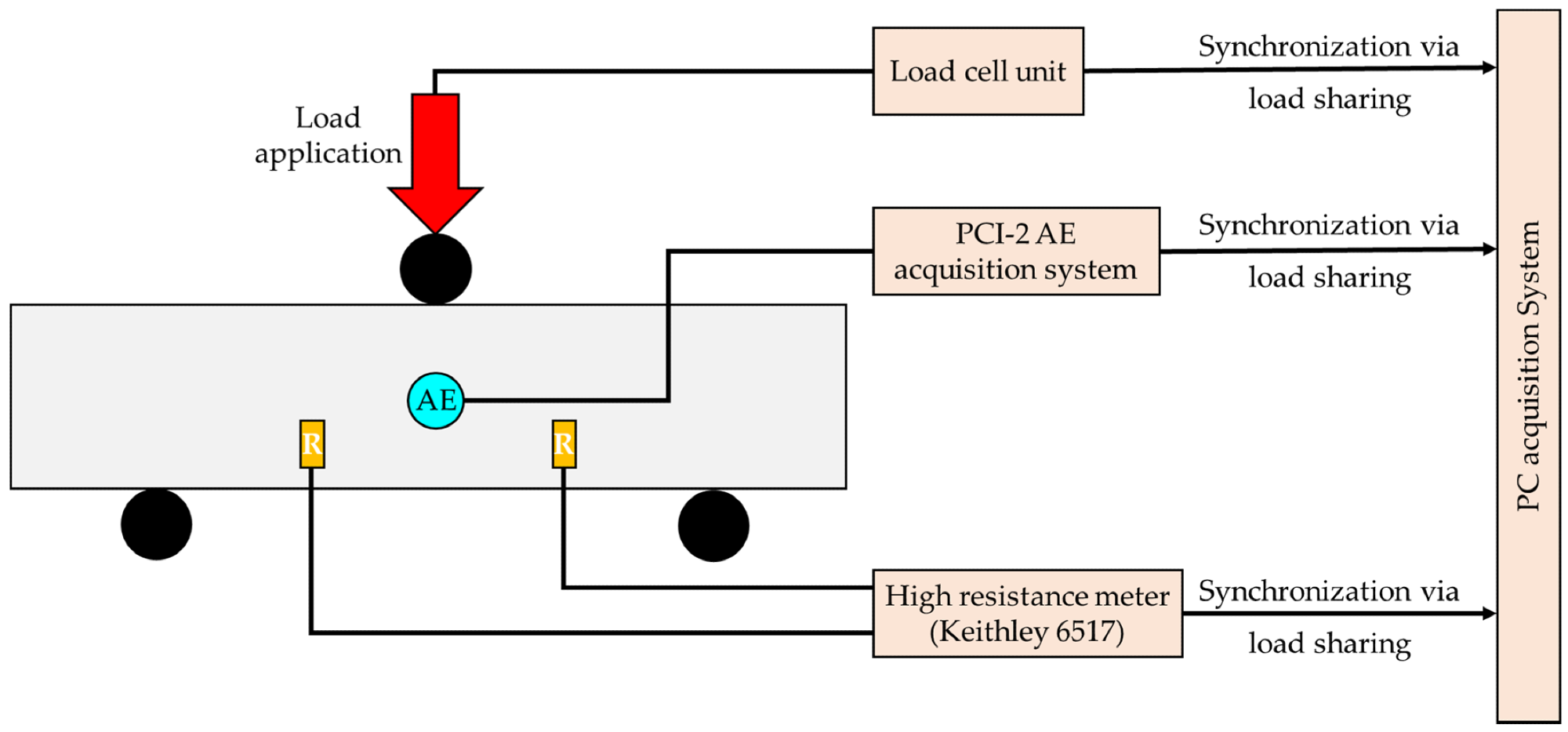

The experimental setup for the concurrent recordings of the electrical resistance and the AEs during the presented 3PB tests.

Other factors, including cementitious material composition such as porosity and aggregates size, also influence the electrical resistance. The measurement of electrical resistance can provide real-time monitoring of the crack propagation and damage development processes, as damage accumulation increases the electrical resistance while healing processes decrease the resistance.

AE is another NDT technique based on the detection of transient mechanical waves generated due to the release of elastic energy bursts during crack propagation and formation. These waves travel in a spherical manner towards the surface of the material, where piezoelectric sensors detect them.

Multiple AE statistics, such as the distribution of AE amplitudes, AE occurrence rate, and the cumulative AE energy rate, can provide crucial information concerning the internal crack evolution processes that dominate the material before the fracture and the overall structural response under mechanical load.

The improved b-value (Ib-value) parameter derived from the AE amplitude distribution is typically related to the impending fracture as its value is changed during the fracturing process. Thus, the temporal variation of Ib-values can indicate a material’s proximity to critical impending fracture.

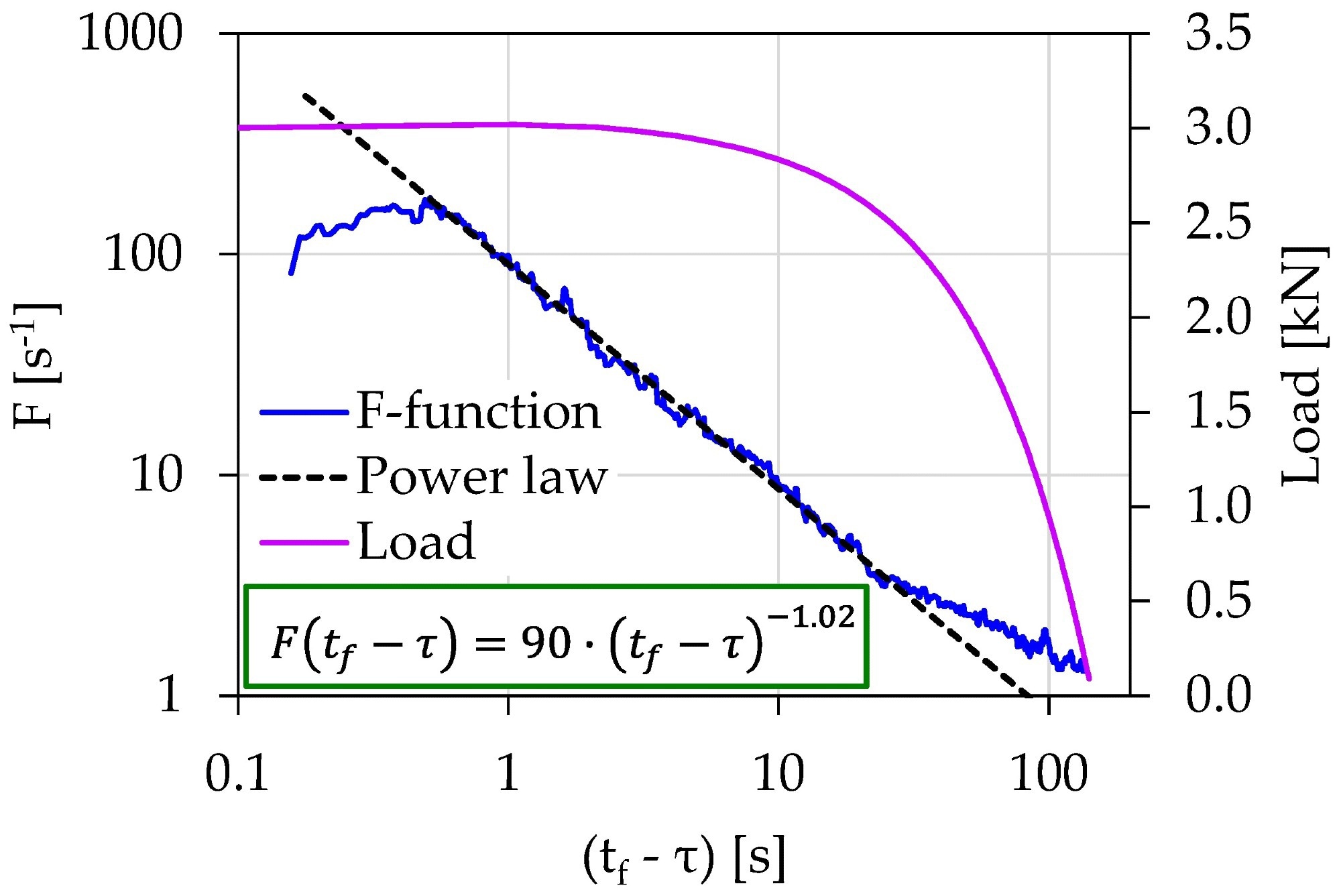

The F-function constitutes another way to analyze the acoustic activity. The temporal representation of the F-function is an effective way to depict the acoustic activity as it highlights the acoustic activity variability, specifically during the last stages before fracture, when most of the acoustic activity occurs.

The Study

In this study, researchers recorded both AEs and the electrical resistance concurrently for sensing damage in three prismatic cement mortar specimens that were subjected to a three-point bending (3PB) load until fracture. The electrical resistance variation was investigated in the reverse time frame in contrast to the AE activity and focusing on the near failure region.

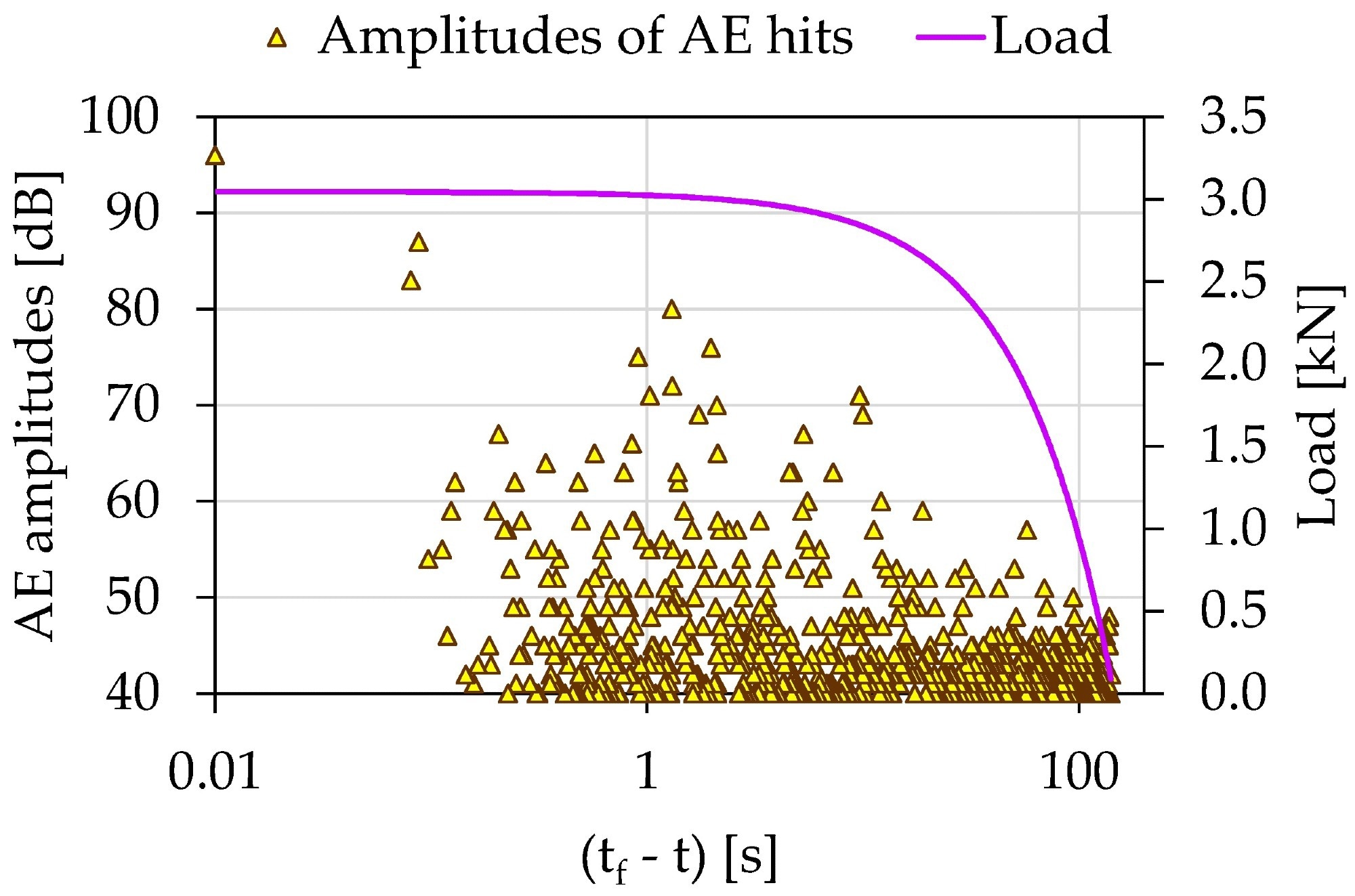

The raw AE activity was demonstrated in terms of temporal variation, along with the corresponding load level for the first time. A comparative study of the temporal variation of the acoustic activity and the electrical resistance was performed in terms of the F-function and Ib-value.

Ordinary Portland cement was used to prepare three prismatic-shaped cement mortar specimens with 50 × 50 × 200 mm3 dimensions. The cement mortars were placed on two 10 mm solid metallic cylinders, with each cylinder placed 85 mm from the center of the specimen. The load was applied through a third solid metallic cylinder at the central cross-section of the specimen.

All experiments were performed under quasi-static conditions with a low loading rate of 22 N/s for experiments Exp-LR1 and Exp-LR2 and a high loading rate of 46 N/s for experiment Exp-HR. The loading system was composed of an Instron 300 DX Static Hydraulic Testing Machine loading frame, and the Bluehill Universal software was used to control the system.

Two copper electrodes plated with gold were implanted in the cement mortar specimen during its preparation, and a 0.2 mm wire was used to connect the electrodes with a high resistance meter to measure the electrical resistance. The PCI-2 AE acquisition system was employed to detect and record the AEs.

The temporal evolution of AE amplitudes in juxtaposition to the load applied for the experiment Exp-LR01 in terms of the “time-to-failure” parameter.

Observations

The electrical resistance and the F-function were described by power laws during the last stages of the loading protocols. A temporal overlap was observed between the validity time regions of the power laws that characterized the temporal variation of the F-function and electrical resistance. In Exp-LR1, Exp-LR2, and Exp-HR, the power laws initiated at approximately 24 s, 20 s, and 10 s before the fracture of the specimens, with the corresponding normalized load values at approximately 86%, 88%, and 87%, respectively.

The results were different for Ib-values. The higher load rate/Exp-HR affected the temporal evolution of the corresponding Ib-value, which crossed the 1.5 value faster than other experiments for a time-to-failure of less than nine s with a corresponding normalized load value of 88%. However, in the Exp-LR1 and Exp-LR2 experiments, the Ib-value crossed the 1.5 value at a time-to-failure of less than 15 s and 5.5 s with a corresponding load value of 91% and 96%, respectively.

The temporal evolution of the F-function in juxtaposition to the load applied for the experiment Exp-LR1 in terms of the “time-to-failure” parameter.

The change in the electrical resistance was attributed to the deformation of the specimen that was caused by the loading and the corresponding changes in the bulk structure. The electrical resistance increased sharply shortly before the fracture of specimens by obeying the resistance power law. The production rate of AE hits that was expressed in terms of F-function also obeyed the F-function power law, which was similar to the resistance power law, shortly before the catastrophic fracture.

In a similar sample with a similar loading protocol, both the electrical signal and F-function obeyed a similar power law when the load reached 90% and 95% of the total strength of the specimen, respectively. No impact of the loading rate was observed on the parameters or the existence of the power laws. A steep decline in the Ib-value/pre-failure index was observed near the value of 1.0, which characterized the pre-failure condition entrance that coincided with the power laws’ initiation time regions.

To summarize, the findings of this study demonstrated that both acoustic activity and electrical resistance could provide equivalent and compatible information regarding the impending catastrophic fracture. The variation in the pre-failure index also supported the findings.

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.