Reviewed by Alex SmithJul 19 2022

An extensively used polymer material’s electronic properties can be enhanced by precisely applied mechanical pressure. According to a team from Martin Luther University Halle-Wittenberg (MLU), this necessitates the material being mechanically processed to an accuracy of a few nanometers.

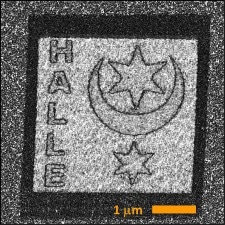

The researchers created this tiny Halle coat of arms with the help of their newly discovered effect. Image Credit: Uni Halle/Kathrin Dörr.

In their latest research, the scientists explain how this previously undiscovered physical effect functions and how it might be applied to brand-new storage technologies. The group has also been successful in creating an electrical pattern in the material that was able to sketch the coat of arms of the city of Halle with a spatial resolution of 50 nm.

The study was published in the journal Advanced Electronic Materials.

Polyvinylidene fluoride (PVDF) is used extensively to create seals, membranes, and packaging films. As it is stretchable, biocompatible, and relatively cheap to produce, it has many useful qualities.

PVDF is also a ferroelectric material. This means it has positive and negative charges that are spatially separated, something which can be utilized for storage technology.

Kathrin Dörr, Professor and Physicist, Martin Luther University Halle-Wittenberg

PVDF is a semi-crystalline material, but unlike crystals, its structure is not entirely ordered, which is a disadvantage.

There is so much disorder in the material that some of the properties that you would actually like to take advantage of are lost.

Kathrin Dörr, Professor and Physicist, Martin Luther University Halle-Wittenberg

The ability of atomic force microscopy to create a specific electric order in the material was accidentally discovered by her team. Using a tip that is only a few nanometers in size, this method typically scans a material sample. The produced vibrations are then measured and assessed using a laser.

Dörr adds, “This enables us to analyze the material’s surface structure at the nano level.”

The tiny tip of an atomic force microscope can also be used to exert pressure on the material sample. The electrical characteristics of the PVDF are also altered, as the physicists at MLU discovered.

The pressure elastically compresses the material at a desired point without shifting the molecules that make it up.

Kathrin Dörr, Professor and Physicist, Martin Luther University Halle-Wittenberg

The material rotates in the direction of the pressure due to its electrical polarization, or electrical orientation. So, at the nanoscale, polarization can be managed and reoriented. The resulting electrical domains are very stable and were still present four years after the initial experiment.

The Halle researchers were able to control the effect so accurately that they were able to draw in the material a nanoscale replica of the city’s coat of arms — likely the smallest in the entire world. The new method might make it possible to use materials like PVDF in cutting-edge electrical and storage applications.

The Deutsche Forschungsgemeinschaft (German Research Foundation, DFG) provided funding for the research.

Journal Reference:

Roth, R., et al. (2022) Mechanical Nanoscale Polarization Control in Ferroelectric PVDF-TrFE Films. Advanced Electronic Materials. doi.org/10.1002/aelm.202101416.