Mechanochromic materials display responsiveness to mechanical pressure. Due to this key material property, they have been widely proposed for use in applications such as display devices, pressure sensing, and recording media.

Thin films must be prepared by a number of processes, such as vacuum deposition and solution fabrication methods like spin coating and bar coating. Solution fabrication methods are beneficial for the preparation of printed electronics, but during these processes, much of the solution which contains dissolved materials are wasted.

To overcome this problem, additive manufacturing methods such as inkjet printing can be employed due to their production of less waste material during the fabrication of patterns and components. Inkjet printing is also beneficial for the preparation of materials due to its low cost, design freedom, and facile operation. This additive manufacturing method has been explored for the production of numerous devices in multiple fields.

There are, however, some key challenges associated with using inkjet printing for the fabrication of mechanochromic materials. In order for materials to be processed for inkjet printing methods, they must be micronized and homogenized. This causes issues because these materials are affected by mechanical stimuli, which hinders their successful commercial production via inkjet printing and other methods.

Currently, studies have not reported many examples of specific applications for mechanochromic materials, although researchers have explored and discussed their properties, mechanisms, and potential benefits.

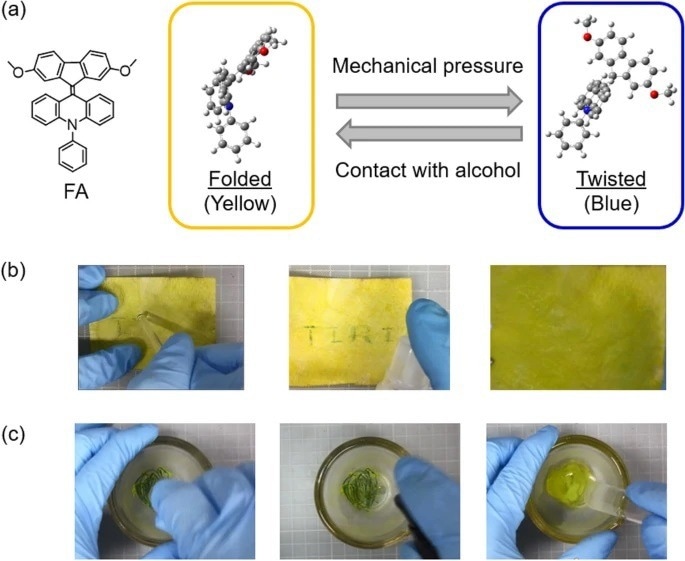

(a) Molecular structure of FA and ground-state mechanochromism. (b) Resetting the mechanochromism using ethanol. (c) Prevention of mechanochromism in the presence of ethanol. Image Credit: Ogumi, K et al., Scientific Reports

The Study

The new paper in Scientific Reports has demonstrated the successful inkjet printing of FAs, a class of thermochromic materials that are overcrowded ethylene derivatives. Mechanical pressure causes a structural change at the molecular level in these materials, from a folded to a twisted conformer, and consequent mechanochromic behavior.

Most mechanochromic materials undergo an emission color change, but FAs display a unique color change, which can be explained by a ground-state mechanochromism causing photophysical changes. Additionally, alcohol causes a response in these materials, which causes the materials to revert from the blue color caused by mechanical pressure to their original color, which is yellow.

Interestingly, FAs with dimethoxy substitutes on fluorine units retain their original yellow color in alcohol even when mechanical pressure is applied to them, such as grinding in a pestle and mortar. Thus, it can be reliably concluded that mechanochromic properties in FAs can be controlled by using alcohol.

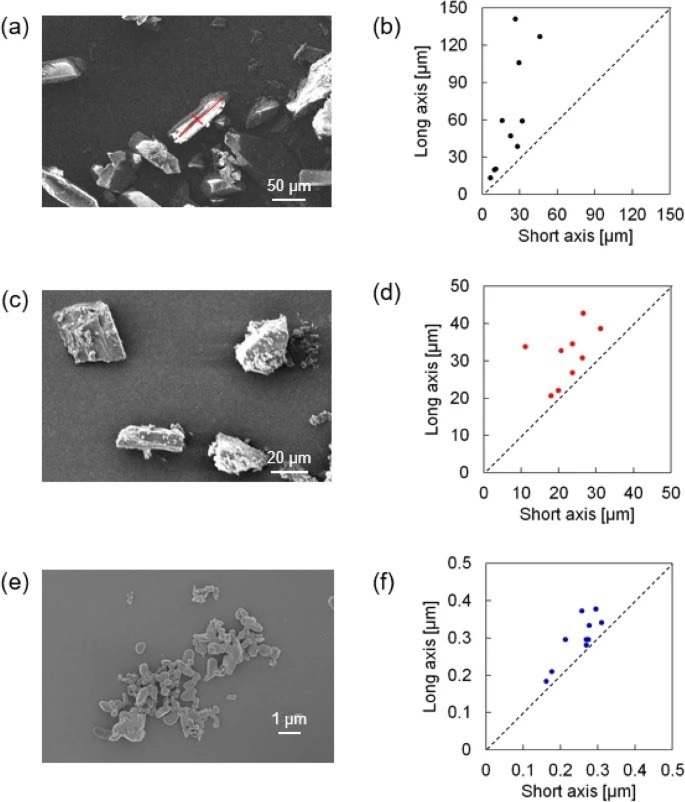

The authors used scanning electron microscopy to confirm the uniform size of the FA particles. Rheology was used to measure the viscosity, and gas absorption equipment provided BET surface area measurements, and additionally, the contact angle and surface tension of prepared inks were investigated.

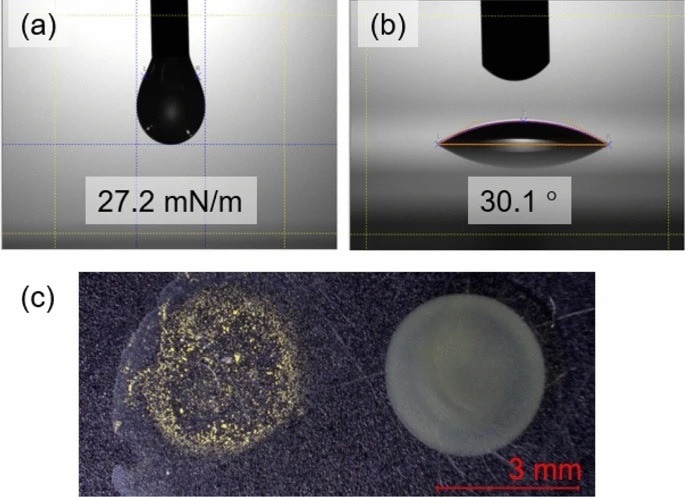

The researchers controlled FA particle size and prepared ink for inkjet printing methods. The physical properties of the formulated FA ink were investigated, such as contact angle, viscosity, and surface tension. FA particles were prepared using bead milling methods. PVA with excess hydroxyl groups shows a similar response to alcohol, which facilitated its selection as a binder, thickener, and dispersant in the formulated FA ink.

The formulated ink avoided the well-reported coffee ring effect due to the presence of PVA, which indicates that the ink has suitable viscosity and inhibits Marangoni flow. A digital microscope was used to image the coffee ring effect. Inkjet printing was used to produce patterns on fabric substrates, and the prepared fabric samples displayed mechanochromic behavior similar to pure FA.

An important observation was that even after PVA was removed, the printed pattern remained intact, demonstrating the fabrication of a mechanochromic material that is wearable, flexible, and has repeatable characteristics.

SEM images of (a) pristine, (c) ground, and (e) bead-milled FA. Graphs of the long axis versus the short axis of 10 particles for (b) pristine, (d) ground, and (f) bead-milled FA. Image Credit: Ogumi, K et al., Scientific Reports

Study Conclusions

By focusing on the influence of alcohol on the responsiveness of FA, the study demonstrated the controllability of mechanochromic behavior. Microscopic FA particles could be prepared by micronization without causing any mechanochromic behavior in prepared materials. The prepared mechanochromic materials were evaluated by the authors and displayed a reversible color change similar to pure FA.

Bead-milled FA particles display the same mechanochromic response as pristine FA particles. SEM characterization revealed that pristine particles have a rod-like fine crystal shape, but under mechanical treatments they become roundish shaped. Bead-milled particles possess the smallest difference between their long and short axes.

Photographs of (a) surface tension and (b) contact angle measurements. (c) Tests for the coffee ring effect (left: only FA in ethanol; right: formulated ink). Image Credit: Ogumi, K et al., Scientific Reports

The bead-milled FA materials are more suitable for inkjet printing due to their size, which is in the range of 200-300 nm. Furthermore, the particles display a small standard deviation. Bead-milled particles possess a much higher BET surface area than pristine and ground FA powders. Additionally, the gas adsorption measurements agreed with SEM observation in terms of FA particle size.

Based on their experimental observations and analysis, the authors have stated that producing FA mechanochromic inks for inkjet printing techniques could be a key area of research in this field in the future.

Further Reading

Ogumi, K et al. (2022) Inkjet printing of mechanochromic fluorenylidene-acridane Scientific Reports 12, 16997 [online] nature.com. Available at: https://doi.org/10.1038/s41598-022-21600-x

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.