Reviewed by Alex SmithDec 6 2022

A new process for manufacturing a vital component of lithium-ion batteries has been developed by scientists at the Oak Ridge National Laboratory of the Department of Energy. As a result of a quicker, less wasteful process that uses less toxic material, the battery is more reasonably priced.

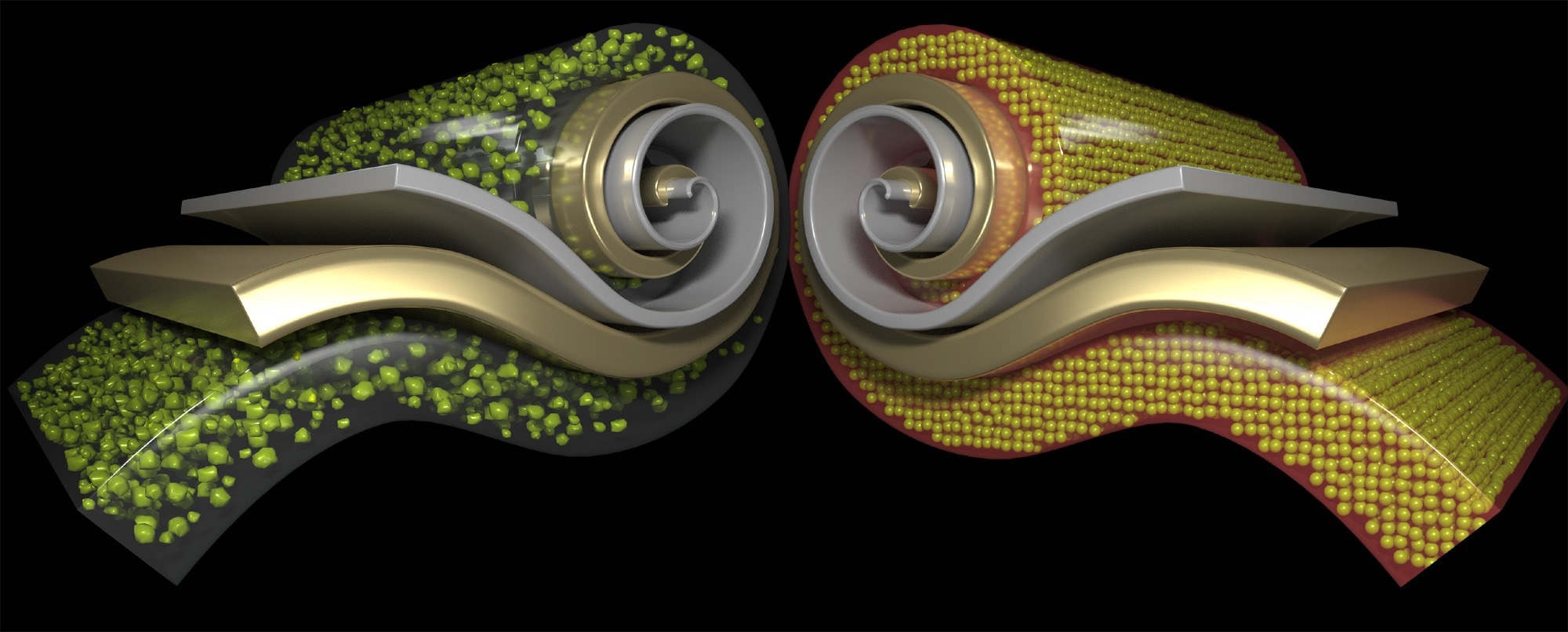

Researchers have developed a new hydrothermal synthesis method that makes a cobalt-free cathode material with more uniform, round, tightly packed particles, shown at right, than is common in today’s cathodes, shown at left, maintaining more stability throughout a charging cycle. Image Credit: ORNL, US Dept. of Energy

The majority of electric vehicles, and items ranging from cell phones to appliances, use lithium-ion batteries, which are made up of an electrolyte between the cathode and the anode. Ions move through the electrolyte from the anode to the cathode in a reaction that transforms chemical energy into electrical energy.

The emphasis on producing energy-dense cathodes sustainably has grown as a result of the push for decarbonization and the demand for electric vehicles. Traditional processing, however, has drawbacks.

The dependence on cobalt, a rare metal mined and refined abroad, is the first barrier. The supply chains and transportation systems used by American manufacturers are at risk as a result of this reliance on foreign suppliers.

Not all difficulties involve the availability of cobalt. The proportion of other metals found in cathodes can also lengthen and make the manufacturing process more dangerous.

For instance, the widespread adoption of a chemical mixing technique for cathode production that necessitates a lot of ammonia for corrosive reactions is a result of high nickel concentration. To reduce acidity, the toxic chemical is used, which raises costs, raises concerns about health and the environment, and wastes a lot of water.

Image Credit: petrmalinak/Shutterstock.com

Image Credit: petrmalinak/Shutterstock.com

In the Journal of Power Sources, researchers from ORNL report that they have created a method for manufacturing a new category of high-capacity cathode materials without cobalt that is cleaner, less expensive, and more effective.

Their hydrothermal synthesis method crystallizes the cathode using metals dissolved in ethanol rather than continuously stirring cathode materials with chemicals in a reactor. The ethanol can be distilled after use and is safer to handle and store than ammonia.

This novel process offers the key advantage of moving the cathode industry to cleaner and more cost-competitive production while putting less burden on our environment.

Ilias Belharouak, Study Principal Investigator and Distinguished Scientist and Head, Electrification Section, Electrification and Energy Infrastructure Division, Oak Ridge National Laboratory

According to Rachid Essehli, lead researcher at ORNL, the hydrothermal synthesis method is also significantly quicker. The amount of time needed to create particles and get ready for the subsequent cathode batch is reduced from several days to 12 hours.

Additionally, the substance created has more uniform, round, tightly packed particles that are perfect for a cathode, according to Essehli. The ORNL team has previously discovered additional cobalt-free mixtures that are effective, but the material created through this study was better at sustaining stability throughout the battery charge cycle.

The new material can be easily incorporated into current battery manufacturing procedures because its properties are comparable to those of today’s cobalt-based cathodes.

Essehli stated that the technology is ready to be scaled up for industrial production and has a patent pending.

This cathode material can give more energy and decrease the cost of electric car batteries.

Rachid Essehli, Lead Researcher, Oak Ridge National Laboratory

The research was supported by the Vehicle Technologies Office of the DOE Office of Energy Efficiency and Renewable Energy. It utilized resources from Argonne National Laboratory’s Advanced Photon Source and the Center for Nanophase Materials Sciences at ORNL. Both are facilities used by the DOE Office of Science.

Journal Reference:

Essehli, R., et al. (2022) Hydrothermal synthesis of Co-free NMA cathodes for high performance Li-ion batteries. Journal of Power Sources. doi:10.1016/j.jpowsour.2022.231938.