In an important step towards a commercially viable green hydrogen industry, researchers have created a less expensive and more energy-efficient method of producing hydrogen straight from saltwater.

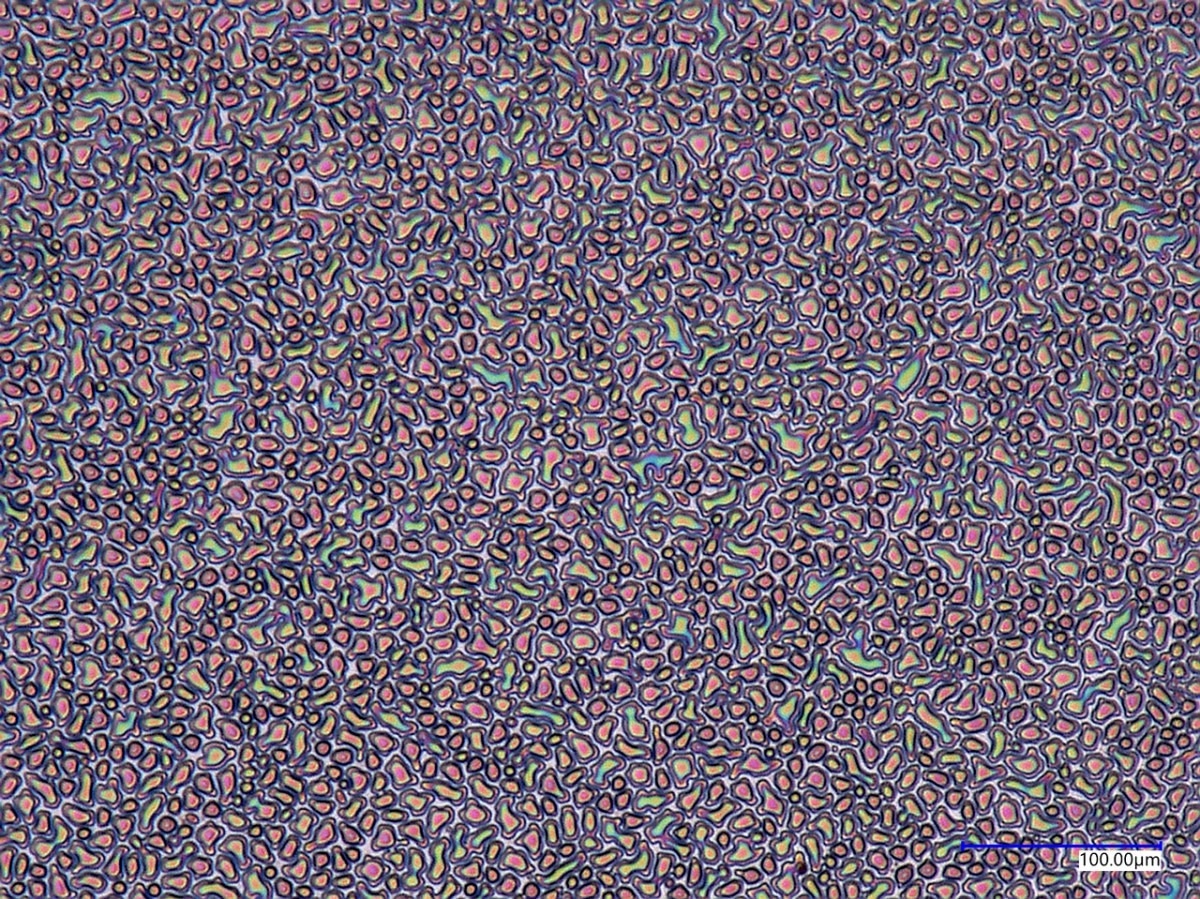

This micrograph image shows an initiated chemical vapor deposition coating made by doctoral student Pengyu Chen in the lab of Rong Yang, assistant professor in the Smith School of Chemical and Biomolecular Engineering in Cornell Engineering. Image Credit: Cornell University

This micrograph image shows an initiated chemical vapor deposition coating made by doctoral student Pengyu Chen in the lab of Rong Yang, assistant professor in the Smith School of Chemical and Biomolecular Engineering in Cornell Engineering. Image Credit: Cornell University

Reactive vapors are used in a new all-dry polymerization method to produce thin films with improved mechanical strength, kinetics, and morphology. The synthesis method might result in superior polymer coatings for microelectronics, advanced batteries, and therapeutics while less harmful to the environment than conventional high-temperature or solution-based fabrication.

This scalable technique of initiated chemical vapor deposition polymerization allows us to make new materials, without redesigning or revamping the whole chemistry. We just simply add an ‘active’ solvent. It is a little bit like a Lego. You team up with a new connecting piece. There’s a ton you can build now that you couldn’t do before.

Rong Yang, Study Co-Senior Author and Assistant Professor, Smith School of Chemical and Biomolecular Engineering, College of Engineering, Cornell University

Yang worked on the study alongside Shefford Baker, Associate Professor of Materials Science and Engineering, and Jingjie Yeo, Assistant Professor at the Sibley School of Mechanical and Aerospace Engineering.

The team’s study was published in Nature Synthesis on February 9th, 2023. Doctoral candidate Pengyu Chen is the lead author. Yang and Yeo were the co-senior authors.

Making inorganic nanolayer materials with zero defects is a common goal in the fabrication of computer microchips and semiconductors, and chemical vapor deposition (CVD) is a common method used to achieve this goal.

Organic polymers perform poorly since the method calls for materials to be heated to temperatures in the thousands of degrees. Low-temperature equivalents of CVD polymerization methods, such as initiated CVD (iCVD), were developed for polymer production.

However, Yang added that it is also constrained because, “over the years, people have grown to the boundary of the chemistry you can make with this method.”

Yang's lab investigates how bacteria colonize polymeric coatings, from the paint used on ship hulls to the coating for biomedical equipment, and how vapor-deposited polymers interact with bacterial pathogens.

She and Chen set out to create a new method for diversifying CVD polymers by adapting a conventional solutions synthesis idea: the use of a “magic” solvent, or an inert vapor molecule, which is not incorporated into the finished product but instead interacts with a precursor to create novel material properties at room temperature.

Yang further added, “It is an old chemistry but with new features.”

This particular instance involved hydrogen-bonding between the solvent and a common CVD monomer.

It is a novel mechanism, although the concept is simple and elegant. Building on this interesting strategy, we are developing a robust and generalizable science of solvation engineering.

Pengyu Chen, Study Lead Author and Ph.D. Student, Smith School of Chemical and Biomolecular Engineering, College of Engineering, Cornell University

Yang and Chen then went to Yeo, whose laboratory has been simulating the molecular dynamics underlying the solvent and monomer interaction and exploring ways to adjust the chemical balance, or stoichiometry, of these systems.

We distinguished the effects of different solvents at the molecular scale and we clearly observed which solvent molecules were more inclined to bind with the monomer. Thus, we can eventually screen which Lego pieces will be able to fit best with each other.

Jingjie Yeo, Study Co-Senior Author and Assistant Professor, Sibley School of Mechanical and Aerospace Engineering, College of Engineering, Cornell University

The resultant thin film was taken to Baker’s lab, where it was examined using nanoindentation testing, and it was discovered that the solvation process had reinforced the material. The polymer coating’s shape changed and the solvent accelerated its growth rate.

This technique can now be used with other methacrylate and vinyl monomers for everything with a polymer coating, such as the dielectric materials in microelectronics, the anti-fouling coating in ship hulls, and the separation membranes that allow purification in wastewater treatment.

The method could enable researchers to alter pharmaceutical products’ permeability for regulated drug release.

Yang further stated, “This adds a new dimension to materials design. You can imagine all kinds of solvents that could form hydrogen-bonding with the monomer and manipulate the reaction kinetics differently. Or you can have solvent molecules incorporated into your material permanently, if you design the molecular interaction correctly. There is so much to explore with this added degree of freedom going forward.”

Zach Rouse, M.S. ‘19, Zheyuan Zhang, M.Eng ‘21, and Baker are the co-authors of the study.

The US Department of the Navy’s Office of Naval Research, the National Science Foundation, and the Fleming Scholarship provided funding for the study.

The Cornell Center for Materials Research, which is funded by the NSF MRSEC program, was used by the researchers.

Journal Reference:

Chen, P., et al. (2023) Engineering solvation in initiated chemical vapour deposition for control over polymerization kinetics and material properties. Nature Synthesis. doi:10.1038/s44160-023-00242-5