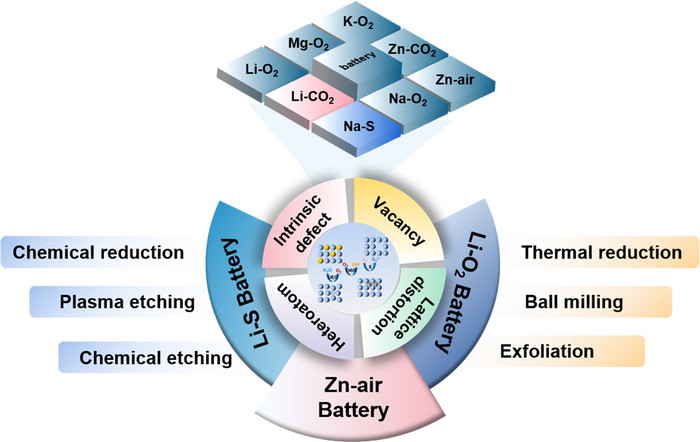

The introduction of defects into electrode materials for metal-based batteries is an effective strategy to improve battery performance, due to defective catalysts having the advantages of high activity, low cost, and environmental friendliness. In this review, the types, synthesis methods, and advanced characterization techniques of defects, the catalytic mechanism, design principles, and the latest research progress of defect electrocatalysts in metal-based batteries are systematically summarized. Image Credit: Chinese Journal of Catalysis.

The development of advanced electrocatalyst electrode materials is crucial to maintaining energy storage efficiency and realizing large-scale electrocatalyst technology development. Researchers have been working hard in recent years to create high-performance, low-cost, and environmentally friendly catalysts.

Faulty electrocatalysts have the advantages of high activity and adequate exposure to active sites, so they are considered an effective strategy for improving the performance of metal-based batteries.

Defect engineering can assist in adjusting the local atomic structure and coordination environment of the battery electrode material, regulating the electronic and structural characteristics of the electrocatalyst and optimizing and improving the battery’s electrochemical performance. Modern and improved defective catalysts have emerged to meet the practical application of metal-based batteries.

A research group guided by Prof. Lei Wang of Qingdao University of Science and Technology in China recently published a systematic review on the catalytic mechanism, design principles, and most recent research progress of defective electrocatalysts in metal-based batteries.

The review elaborates on the methodologies for introducing defects into electrode materials as well as defect characterization technology, and it summarizes the common tools for investigating the catalytic mechanism of defects in electrocatalysts: DFT calculation and in-situ characterization techniques.

The impact of defects in electrocatalysis and the design principles of defect metal-based battery electrode materials are concluded, beginning with the mainstream reaction mechanism of electrocatalysis (OER, ORR, S catalysis, etc.). Furthermore, the most recent research progress on various types of defects for several important metal-based batteries are reviewed (lithium-sulfur battery, zinc-air battery, lithium-oxygen battery, etc.).

Ultimately, the current challenges and anticipations in the field of defect electrocatalysis are examined, with the goal of improving the activity of catalytic electrode materials via defect engineering and promoting the commercialization of clean energy storage devices.

This review not only summarizes the huge potential of defect engineering in the field of electrocatalysis, but it also serves as a valuable guide for the rational design of new efficient catalysts.

The research was funded by the Natural Science Foundation of Shandong Province (ZR2021QE037), the National Natural Science Foundation of China (51802171, 52072197), the China Postdoctoral Science Foundation (2020M682135), the Postdoctoral Innovation Project of Shandong Province (202102039).

Postdoctoral Applied Research Project of Qingdao Outstanding Youth Foundation of Shandong Province, China (ZR2019JQ14), Taishan Scholar Young Talent Program (tsqn201909114), Major Basic Research Program of Natural Science Foundation of Shandong Province (ZR2020ZD09) also supported the research.

Journal Reference

Liu, X., et al. (2023) Defect engineering of electrocatalysts for metal-based battery. Chinese Journal of Catalysis. doi.org/10.1016/S1872-2067(22)64168-8.