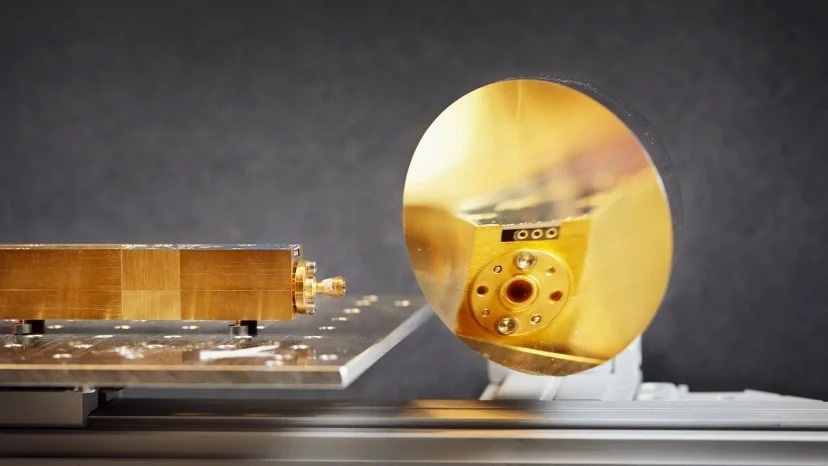

Researchers at Chalmers University of Technology have developed a high-frequency radar technique that can measure how particles behave in fluidized beds with unrivaled precision. The radar transmitter and receiver can convert lower frequencies into extremely high frequencies of up to 340 GHz. The signal is then transmitted through the horn antenna and uses a gold mirror, an off-axis parabola, to redirect the beam towards the fluidized bed, enabling very precise measurements with high resolution in space and time. Image Credit: Anna-Lena Lundqvist

But the process that happens within a fluidized bed is known to be extremely complicated and—as a result of the lack of effective measurement methods—has remained largely unidentified.

Now, scientists from Chalmers University of Technology in Sweden have come up with a high-frequency radar method that can measure exactly what is happening within a fluidized bed with unparalleled accuracy. This discovery resulted in entirely new and highly efficient processes in various industries, such as energy conversion.

Fluidized bed combustion is known to be one of the leading technologies that have been utilized in the thermal power plants of the world. This technology shifts solid fuels, like biomass and waste, into district heating and electricity.

Also, fluidization technology is basic to several other processes that are forecasted to play a significant role in the shift of energy systems, and in circular resource flows—like in energy storage, carbon capture, and also the production of hydrogen and other fossil-free fuels.

At the Chalmers University of Technology, scientists have come up with a radar method that has the potential to offer an elaborate characterization of the flow of solids in fluidized beds, the absence of which has been restraining the development of such processes.

Earlier, fluidized beds are known to be the most efficient technology for shifting solid biofuels into energy. This technology leads to an effective and consistent rate of combustion since the solid particles acquire a liquid-like state which helps to spread the heat uniformly in the combustion chamber.

Fluidization technology depends on a gas being blown via a bed of small sand-like particles in a reactor, so that such solid particles, the fuel, and the gas are completely mixed.

Like a Sandstorm and a Wildfire in One

For even greater efficiencies in this process to be achieved, one needs to be able to understand and regulate how the solid particles act in the mixture. However, the reactor environment is frequently hot, dirty, and corrosive—like a sandstorm and a wildfire in one—effectively avoiding any kind of measurement and thus restricting the comprehension of what is taking place within the reactor.

The Chalmers scientists’ new solution to this issue is an extremely high-frequency radar method that has the potential to quantify the flows of solid particles in fluidized beds with matchless accuracy.

Having gained motivation by the pulse-Doppler radar that has been utilized to track phenomena like rain or snow, this is the first time the method has been illustrated in the context of a fluidized bed. This discovery is anticipated to set the stage for new and highly efficient processes in numerous industries.

The use of the high-frequency terahertz radar instrument demonstrated in our study has the potential to revolutionize how fluidized bed technology can be designed and used in many different industrial sectors – from energy conversion to the food industry and drug production.

Diana Carolina Guío Pérez, Researcher in Energy Technology, Chalmers University of Technology

Carolina Guío Pérez added, “This is one of very few demonstrations of the use of pulse-Doppler radar technique at submillimetre wave frequencies, and it is the first time ever that it has been used for making measurements in a fluidized bed.”

Unrivaled Measurement Accuracy

Whilst the measurement methods generally utilized in fluidized beds are low-resolution, produce outcomes that are hard to decipher, or result in disturbances in the flow, the Chalmers researchers’ high-frequency terahertz radar method could penetrate the reactor from the outside and quantify the behavior of the particles within it without causing any disturbance to the flow.

Also, the radar method could quantify the velocity and concentration of the solid particles concurrently with great accuracy and high resolution in space and time. This implies that even the least changes in the flow could be detected in real-time, which is significant while industrial processes have been monitored and controlled.

For the very first time, in the scientist’s study, the method was illustrated in practice, in a 3-m high circulating fluidized bed boiler model. Their study outcomes displayed a measurement quality that surpassed the quality that has been achieved by the techniques that were utilized earlier in the field by a big margin.

We have been able to show that pulse-Doppler radar technique at frequencies up to 340 GHz can measure both the distribution of particles and their velocity inside a fluidized bed at a much higher resolution than other technologies can.

Marlene Bonmann, Post-Doc, Terahertz and Millimetre Wave Laboratory, Chalmers University of Technology

Bonmann added, “This is information that has long been lacking in the field and will make it possible to improve and scale up process reactors and—in the case of energy conversion—reduce emissions of unwanted residual products.”

Diana Carolina Guío Pérez added, “The knowledge that can be acquired with our high-frequency terahertz radar technique has the potential to break new ground in our understanding of solids flows in fluidized bed reactors and other solids handling units.”

“For example, it can lead to improved operation and design of the reactors needed in existing and completely new fluidized bed-based conversion processes, such as carbon capture and storage, energy storage, and thermal recycling,” stated Diana Carolina Guío Pérez.

Journal Reference

Carolina Guío-Pérez, D., et al. (2023) Radar-based measurements of the solids flow in a circulating fluidized bed. Fuel. doi.org/10.1016/j.fuel.2023.128232.