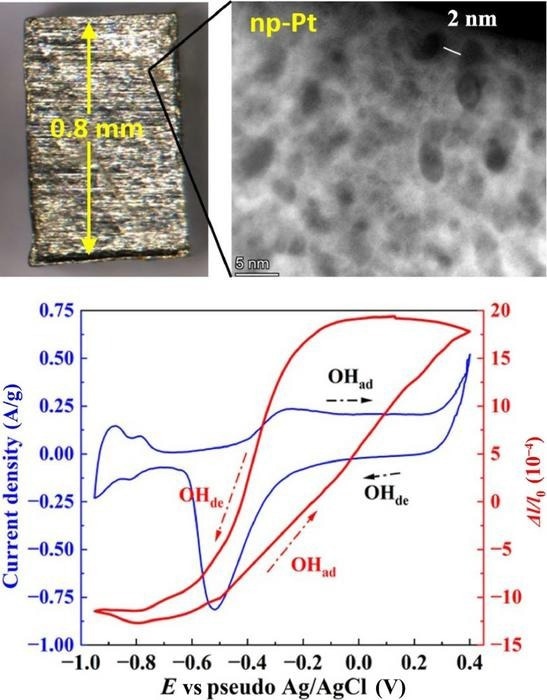

Np-Pt is made up of interconnected small-diameter ligaments, or strands, of platinum as small as two nanometers (10-9 m) in diameter with tiny pores in between. The small nature of the platinum ligaments and the numerous tiny pores improve the structural stability of the material and its energy conductivity, as indicated by the graph illustrating current density, or the amount of charge flowing through a particular area in a given time, and relative length change. Image Credit: Energy Materials and Devices, Tsinghua University Press

Moreover, it should boast exceptional mechanical properties to endure the physical stress of continuous movement. Recently, nanoporous platinum (np-Pt), a platinum matrix embedded with minuscule pores to enhance energy conduction, has been produced on a large scale and in a cost-effective manner. This advancement positions np-Pt as an ideal and more feasible material for actuators.

A team of material scientists from Hamburg University of Technology in Germany developed an ultrafine-ligament np-Pt material consisting of a haphazardly interconnected network composed of extremely fine platinum strands, or ligaments, as diminutive as 2 nm (10-9 m) in diameter.

This network structure also engenders minuscule pores between these strands, enhancing the movement of electrons or charged atoms within the material. Crucially, the team employed an efficient manufacturing technique that reduced the associated costs of synthesizing np-Pt. By reducing the diameter of the Pt strands, both the surface-to-volume ratio and the mechanical stability of the np-Pt material were augmented, thereby enhancing the material's performance as an actuator.

The study was published in Energy Materials and Devices on October 17th, 2023.

In comparison to various other nanoporous metals and materials under investigation for potential use as actuators, the team found that np-Pt exhibited greater physical resilience. Consequently, it is more likely to excel as a sensor or detector material when compared to other fragile nanoporous materials.

The fine ligament size of np-Pt could provide an enhanced surface area which makes the material a promising… catalyst of chemical reactions as well as an actuator material.

Haonan Sun, Study First Author and Researcher, Research Group of Integrated Metallic Nanomaterials Systems, Hamburg University of Technology

As a catalyst, np-Pt expedited the rate of specific chemical reactions.

The most distinctive aspect of the study lay in the methodology employed by the researchers to fabricate the np-Pt material.

The main breakthrough in this research is that we obtained bulk np-Pt by electrochemical dealloying. Past studies on np-Pt were all based on nanoparticles or films that were prepared using more expensive commercial Pt particles. So the easy and cheap method of dealloying increases the practicality of np-Pt and makes further research possible.

Haonan Sun, Study First Author and Researcher, Research Group of Integrated Metallic Nanomaterials Systems, Hamburg University of Technology

Dealloying refers to a process of selective leaching or corrosion wherein one component of an alloy or a blended material is selectively extracted. Initially, before the dealloying process, the material remains a homogeneous blend.

Post the selective leaching procedure, the more chemically active constituent of the blended materials is partially removed, thereby leaving behind minute pores. In the context of np-Pt, it was manufactured through the selective leaching of copper from a platinum-copper alloy (Pt15Cu85) using sulfuric acid (H2SO4).

Producing np-Pt in larger bulk quantities had not been achieved earlier. The research team highlights that the effective performance of bulk np-Pt sets a precedent for developing other nanoporous metals that could be explored for their applicability as potential actuator materials, strain sensors, or catalysts for chemical reactions.

Having established np-Pt's efficacy as an actuator material, the team anticipates delving into its impact on chemical reactions as the next step in their research.

The next step of this study is to investigate the chemical catalyst property of our np-Pt. We have already found some very interesting phenomena with bulk np-Pt on the oxygen reduction reaction which combines oxygen and hydrogen to form water… and we would like to do some deeper research on that.

Haonan Sun, Study First Author and Researcher, Research Group of Integrated Metallic Nanomaterials Systems, Hamburg University of Technology

Yizhou Huang from the Research Group of Integrated Metallic Nanomaterials Systems at Hamburg University of Technology in Hamburg, Germany and Shan Shi from the Research Group of Integrated Metallic Nanomaterials Systems at Hamburg University of Technology and the Institute of Materials Mechanics at Helmholtz-Zentrum Hereon in Geesthacht, Germany contributed to the study.

Journal Reference

Sun, H., et al. (2023). Bulk Nanoporous Platinum for Electrochemical Actuation. Energy Materials and Devices. doi.org/10.26599/emd.2023.9370006.