A recent review article published in Advanced Materials explored the potential of artificial intelligence (AI) and machine learning (ML) in transforming thermoelectric (TE) materials design.

The authors highlight how cutting-edge ML models, including graph neural networks (GNNs), transformer architectures, and surrogate models, understand and engineer defects across multiple scales. AI-enhanced defect engineering strategies, such as entropy and dislocation engineering, composition optimization, grain boundary design, and inverse design techniques, were examined for producing TE materials with targeted properties.

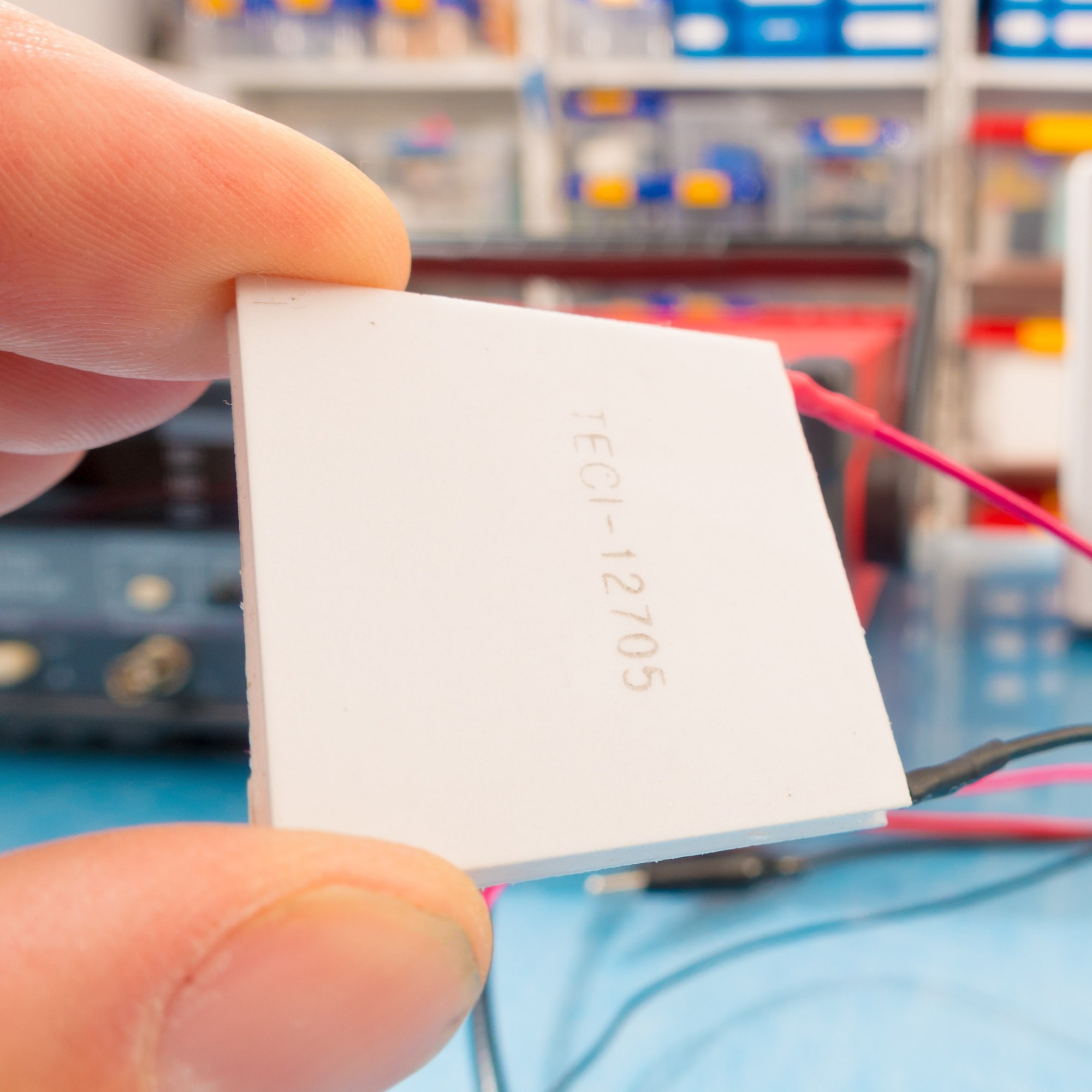

Image credit: luchschenF/Shutterstock.com

Current Challenges

TE materials can directly transform heat into electricity or vice versa and form an important category of energy materials to meet future energy challenges. They find applications in solid-state cooling, waste heat recovery, renewable energy systems, and Internet-of-Things sensors.

However, realizing a high TE figure-of-merit (zT) necessitates simultaneous optimization of Seebeck coefficient, electrical conductivity, and thermal conductivity. The above properties are interdependent and generally constrained by conflicting trade-offs. Additionally, they are sensitive to the multiscale defect structures of materials. This sensitivity creates a high-dimensional optimization problem, complicating the search for ideal TE performance.

Many techniques have been proposed to address this challenge, including the convergence of electronic bands, using low-dimensional materials, and resonant-state doping. Additionally, modern computational approaches such as first-principles calculations and extensive screening have helped achieve high values of maximum zT of two in some TE materials, such as Cu2Se, SnSe, GeTe, PbTe, or Bi2Te3/Sb2Te3 superlattices.

However, the complex defect configuration hinders comprehending the underlying mechanism and obscures the scalability of TE materials. Despite the high efficiency (10%–15%) of TE materials with zT equal to two, they still lag behind other technologies.

The review suggests that reaching efficiencies comparable to photovoltaics (≈30%) would require zT values approaching 10, a benchmark far beyond current materials. This highlights the need for deeper insight into defect behavior and the discovery of scalable materials.

ML for Materials Design

Recently, ML has considerably accelerated the discovery and design of materials. By leveraging vast datasets from simulations and experiments, ML algorithms help predict important property-structure relationships in materials, including electrical transport, thermal transport, magnetism, optical behavior, and vibrational properties.

ML enables the generation of candidate materials under particular conditions and assists in discovering and synthesizing autonomous materials. Additionally, it improves characterization methods by enhancing the analysis of spectroscopy techniques such as Raman spectroscopy, electron microscopy, neutron and X-ray scattering, and electrochemical impedance spectroscopy.

The key strength of ML methods is their ability to handle multiscale simulations of energy materials. This bridges the gap between first-principles electronic structure calculations and mesoscale transport simulations, offering a holistic understanding of material behavior.

These data-driven methods can mitigate the persistent “curse of dimensionality” in energy material design. Additionally, ML provides powerful tools to endorse environmentally conscious innovation by enabling efficient optimization of high-performance materials while minimizing environmental impact. Notably, transformer-based models such as CraTENet are already being used to screen large materials in spaces for optimal TE properties.

TE Design with Defects and ML

Defect engineering is an essential approach to improving TE materials. Controlling defects enables tuning the structure and properties of the materials to optimize performance. However, defects destroy the perfect structure and introduce structural complexities, hindering modeling the precise relationship between defect tunability and material performance.

Consequently, defect engineering in bulk TE materials is mainly experimental, with limited theoretical or computational guidance. The increasing power of ML and AI is transforming the optimization process, specifically in high-dimensional optimization problems. For bulk TE material design, ML allows for efficient exploration of complex defect configurations and the determination of optimal configurations.

Recent models such as DopNet explicitly encode host-dopant interactions, improving the prediction of defect-induced property changes. High-quality data and effective representations of defective structures are critical for successfully applying ML to defect engineering.

Despite the advancement of ML in defect engineering for TE, current ML-based methods still face some challenges. For instance, these methods rely on composition-only input representations, which may overlook crucial structural information, especially in systems with a critical role of local atomic configurations or defect-site geometries. Additionally, the direct implementation of specific neural networks is inefficient for modeling defective structures.

Emerging solutions include graph neural networks incorporating virtual models or defect channels, and E(3) -equivalent models that preserve spatial symmetries in defective systems.

Download your PDF copy now!

Conclusion and Future Prospects

Despite the extensive efforts in TE engineering, the search for materials with high zT values has just begun. Finding candidates with even zT > 2 has been a long-standing challenge. Moreover, today's progress indicates that the power of AI for TE design is still in its infancy, with significant room for improvement.

A more extensive TE database is required to enhance the efficacy of AI algorithms. Such datasets should include a wider range of defect configurations and host materials. Automated dataset construction methods, such as natural language processing and large language models, are becoming increasingly important in this context. Additionally, integrating these datasets with experimental data will help overcome current limitations, enabling a better understanding of TE materials.

Notably, this review mainly focused on using ML to optimize zT by exploring the defect-induced structural complexity, aiming to integrate defect engineering with ML for enhanced TE performance. However, material complexity is not limited only to defects. Other physical phenomena beyond the traditional Fermi gas model, such as hybrid organic–inorganic systems, intricate electronic band structures, and correlated electron systems, also hold considerable potential for improving zT.

Advanced ML approaches, including deep generative models and persistent homology, offer promising tools to explore such complex systems. ML can be applied to consider these in materials searching or optimization.

Jornal Reference

Fu, C. (2025). AI‐Driven Defect Engineering for Advanced Thermoelectric Materials. Advanced Materials. DOI: 10.1002/adma.202505642, https://advanced.onlinelibrary.wiley.com/doi/10.1002/adma.202505642

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.