A Stanford-led team has pushed iron to a rarely achieved oxidation state, opening the door to powerful, cobalt-free lithium-ion batteries with greater energy and stability.

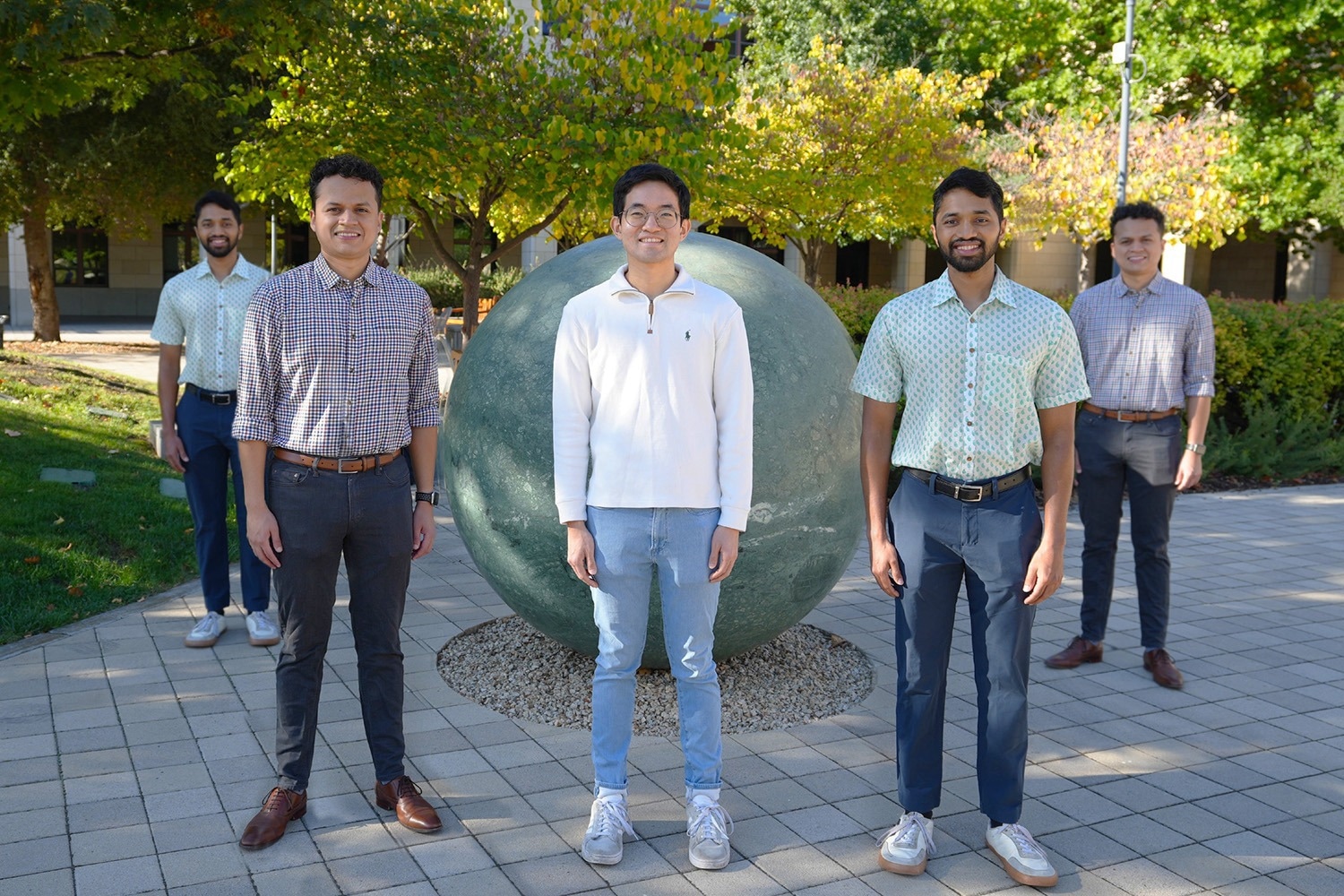

When three becomes five. Eder Lomeli, Edward Mu, and Hari Ramachandran (front row, from left) led an international team in getting an iron-based material to give up and take back five electrons, rather than the previous limit of three. Image Credit: Bill Rivard/news.stanford.edu

When three becomes five. Eder Lomeli, Edward Mu, and Hari Ramachandran (front row, from left) led an international team in getting an iron-based material to give up and take back five electrons, rather than the previous limit of three. Image Credit: Bill Rivard/news.stanford.edu

The team developed a storage material with higher energy density for iron-based batteries. This advancement may enhance applications in MRI technology and magnetic levitation. The study was published in the journal Nature Materials.

The findings have immediate potential applications in lithium-ion batteries; however, they may also be used in magnetism-related fields, such as magnetic resonance imaging (MRI) machines in the medical sector and magnetic levitation technologies for high-speed trains. Additionally, these findings could contribute to advancements in the development of superconductors.

Iron frequently engages in reactions that involve the release and reabsorption of electrons, referred to as redox reactions. These reactions play a significant role in various aspects of life, from the transportation of oxygen within the human body to the growth of plants and the rusting of bicycles.

Iron atoms generally restrict their involvement in these reactions to two or three of iron's 26 electrons. But a PhD student involved was convinced that he could enhance this process, encouraging the material to consistently release five electrons per iron atom and subsequently accept five during the charging phase.

The researchers believe that preventing the iron atoms from being adjacent to one another within the crystal structure of the material is crucial. If this is not achieved, side reactions, such as the bonding of oxygen atoms, hinder iron's ability to attain a higher oxidation state. If implemented in a lithium-ion battery cathode, this advancement could allow the battery to store increased energy and deliver a higher voltage.

In 2021, when beginning the work, the team faced challenges in maintaining the crystal structure of the battery material during the charging process. They concluded that significantly reducing the size of the particles in their materials might provide a solution.

Making the particles very small, just 300 to 400 nm, or billionths of a meter, in diameter, about 40 times smaller than before, turned out to be a challenge.

Hari Ramachandran, Ph.D. Student, Stanford University

In 2022, Ramachandran and Mu found a solution.

Literally, a solution. We grew our crystals out of a carefully concocted liquid. In our electrochemical tests, the material seemed to get iron to reversibly give up and later take back five electrons while the crystal structure remained stable.

Edward Mu, Ph.D. Student, Stanford University

This is what the spectral images from Ramachandran and Mu indicated was enhancing the energy potential of the material. To verify this, the team collaborated with Lomeli in 2023.

It’s too simple to say that iron is the hero or oxygen is the hero when it comes to contributing free electrons. The atoms in this very nicely arranged material behave like a single entity.

Eder Lomeli, Stanford University

Iron’s Ascension

In recent years, iron has increasingly supplanted cobalt and nickel as the primary metal used in lithium-ion cathodes worldwide, particularly for electric vehicles and stationary storage systems. Iron is significantly more affordable than both cobalt and nickel.

Furthermore, 70 % of the world's cobalt supply is sourced from the Democratic Republic of the Congo, with China exerting control over a substantial portion of the Congo's production. Reports indicate that these mines often employ children under perilous working conditions, and the mining activities have led to deforestation as well as the contamination of rivers and soil.

Due to these challenges, 40 % of the lithium-ion batteries produced today incorporate cathodes composed of lithium, iron, and phosphorus.

This cathode “is rapidly growing into the most popular battery cathode chemistry for both electric vehicles and grid-scale stationary storage applications,” said Ramachandran.

However, these cathodes do not operate at high voltage, and the batteries produced from them also lack high voltage. Automotive manufacturers and other producers have navigated the limitations of low-voltage technology to achieve commercial success without relying on nickel and cobalt.

“A high-voltage, iron-based cathode could avoid the tradeoff between higher voltage and higher-cost metals that previously dominated cathode materials. The best of both worlds,” said Mu.

To develop a high-voltage, iron-based, reversible, and stable cathode, Ramachandran and Mu meticulously synthesized their material using lithium, iron, antimony, and oxygen, as proposed by Gent, which is referred to as "LFSO."

Strength Through Bending

To explore the structure and functionality of LFSO more thoroughly and to contrast it with previous iterations that were ineffective, the team conducted examinations using beams of X-rays and neutrons at the Lawrence Berkeley, Oak Ridge, and Argonne national laboratories.

Despite having that information, the team was still unable to determine precisely what was occurring.

Combining their experimental findings with computational modeling helped them to reach a consensus: In contrast to the earlier material, which deformed and crumbled after lithium ions were extracted and moved towards the anode during charging, the material composed of nanoparticles flexed slightly to adjust to the empty lithium sites and stayed whole throughout the cycling process.

“Scientists have rarely reported high-voltage iron-based materials. Our detailed electronic structure exploration of this iron species provides conclusive evidence of oxidation beyond three electrons,” said Chueh.

Having established the method to elevate iron to a high oxidation state and maintain it, Chueh stated that the core team is now focused on addressing practical engineering challenges, adjusting particle shapes, material composition, and chemical properties to identify a viable combination for commercial use.

A top priority is to discover a substitute for the antimony in LFSO. Similar to cobalt, it is a costly mineral with considerable supply chain risks; however, the developing research team has multiple alternative candidates under consideration.

Journal Reference:

Ramachandran, H., et al. (2025) A formal FeIII/V redox couple in an intercalation electrode. Nature Materials. doi.org/10.1038/s41563-025-02356-x