Nov 24 2006

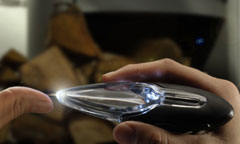

Is it at all possible to improve a mundane everyday item such as a pair of tweezers? After all, it has the simplest of forms and has worked reliably for as long as anyone can remember. "Most definitely," is the reply from Ralph Schneider as he reaches for a streamlined item made of plastic with a black head and two transparent arms. As if by magic, the pincers light up, directing the light to the tips and illuminating a small point on the desk top. Perfect for shining the spotlight on a thorn that has to be removed…

"This little item has the capacity to provide the electronics market with new impetus," explains Ralph Schneider. The pair of tweezers, developed in a project he supervised, is a prototype that uses an innovative and completely invisible switching technology. Today, the former mechanical engineering student is right in the middle of things instead of just watching events unfold. What began a few months ago as a degree thesis at Bayer MaterialScience AG quickly resulted in a permanent appointment in the Creative Center at one of the biggest plastics manufacturers in the world.

A high-tech product in the shape of a lobster claw: the innovation known as "EXTRACT®" combines the mechanical properties of chemical materials - which also conduct light or electricity - with electronics. It represents an area of technology that is becoming increasingly important for industry.

Specialists call this new technology "mechoptronics," that is, the interaction between mechanics, optics and electronics.

Eckard Foltin, head of the Creative Center, sums it up nicely", Our aim is to implement creative solutions to turn our customers’ ideas into reality.

We refer to this process as "VisionWorks". The tweezers combine materials in a way that has never been seen before. In addition to the well-known design-related functions, we have made it possible for them to conduct light and, in future, they will also be able to transfer data. These features pave the wave for countless new applications, for example, in the automotive industry."

The tweezers are based on the "SmartSwitchSystem." It lets light flow through the transparent arms when they are touched - without use of either buttons or wires. The "switchless switch" is made of the transparent polycarbonate Makrolon®. The plastic is coated with a new polyurethane coating, which Bayer MaterialScience developed in cooperation with its partner company KRD Coatings GmbH. It is abrasion resistant, extremely chemically stable and elastic. The most important characteristic is its electrical conductivity. When the arms are touched, the circuit is completed and the light goes on. The battery, LEDs and other electronic components are integrated in the head of the tweezers. The head is made from the thermoplastic polyurethane Desmopan®, which protects the sensitive internal electrical components from mechanical load, dust and water splashes.

The result of the interdisciplinary cooperation between material experts, engineers, business economists and external specialists from the Düsseldorf-based innovation agency"marktunddesign.com" not only sets the hearts of technology fans racing. The organically flowing lines also appeal to anyone who likes stylish design. And the sense of touch is also stimulated - "EXTRACT" is pleasantly smooth and sits comfortably in your hand. Both senses come together in that magical moment when the slightest of touches makes the tweezers light up and transforms the "mundane object"

into something special for just an instant.

With sales of EUR 10.7 billion in 2005, Bayer MaterialScience AG is one of the world’s largest polymer manufacturers. Its main fields of activity are the production of high-tech polymer materials and the development of innovative solutions for products used in many areas of everyday life. The main consumer sectors are the automotive, electrical/electronics, construction, sports and leisure industries. Bayer MaterialScience has production facilities at 40 sites around the world and a workforce of approx. 18,800. Bayer MaterialScience is part of the Bayer Group.