Interview conducted by Alex SmithMar 9 2022

Interview conducted by Alex SmithMar 9 2022In this interview, AZoM talks to Anna Walkiewicz, Application Specialist at Quorum Technologies, about the sample preparation technique glow discharge, how it can be used in Transmission Electron Microscopy and even beyond that.

Can you introduce yourself, your role and Quorum Technologies’ work?

My name is Anna Walkiewicz. I am an application specialist at Quorum Technologies, a company that specialises in manufacturing sample preparation systems and cryo solutions for Electron Microscopy Imaging.

We produce equipment like critical point driers, coaters and glow discharge systems that is necessary to make samples suitable for imaging techniques that involve electron beam scanning.

What benefits could a user expect from glow discharge treatment?

We mainly use glow discharge for Transmitted Electron Microscopy, for preparation of the grids, however the technique is also useful for other microscopies, where samples that are dispersed in a liquid are applied onto a surface before imaging.

With glow discharge we can change the substrate surface properties and this way direct how our sample will behave on that substrate.

For TEM we use TEM grids that have a form of a disk with a metal mesh. Those grids could be of different build, they can have additional layers of polymer, lacy or holey carbon. The surface properties of TEM grids that are taken straight from the box are not uniform. This can cause unwanted effects like agglomeration, aggregation or very little of the sample set on the support.

Glow discharge is used to alter wetting properties of surfaces and make the charge of the surface uniform. This helps in homogenous dispersion of the sample on the surface and can also direct orientation of molecules on the support.

What are some of the factors to consider when working with glow discharge?

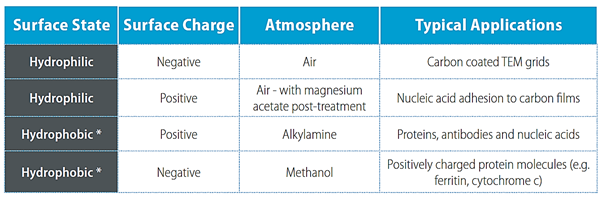

When working with glow discharge, we need to consider how we want to alter the properties of the surface or in other words, if the hydrophilic or hydrophobic surface is the best in the case of a particular sample.

For bio molecules, especially proteins and nucleic acids, the type of the charge is an important factor. Positively charged molecules will bind better to the negatively charged surface.

Hydrophilic, negatively charged surfaces tend to be in the highest demand.

Image credit: Quorum Technologies

What is the science behind glow discharge treatment?

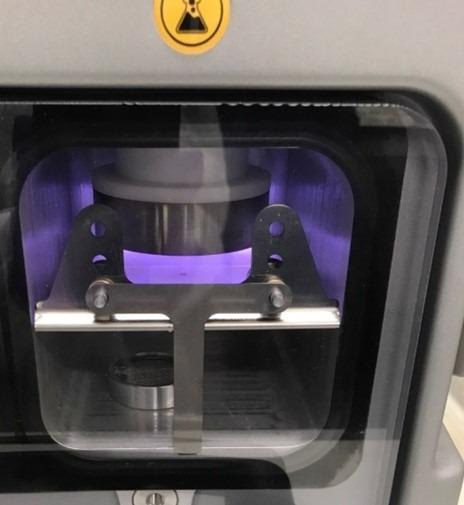

The name ‘glow discharge’ refers to a characteristic glow of plasma - an ionised gas that is overall neutral but consists of negatively and positively charged regions.

When a gas is ionised, ions and electrons are produced. When there are enough electrons, they form more ions when colliding with a neutral atom of gas.

This process occurs via inelastic collisions. Elastic collisions do not do anything useful for our purposes, but inelastic collisions produce either ions or free radicals - two species that are of interest, they react with the surface and change its properties.

When a free radical is neutralised, it produces a photon of a characteristic wavelength. That photon is responsible for the very characteristic glow colour that we see in the glow discharge.

In methanol (a) and in-amylamine (b) glow discharge treatment characteristic glow. Image credit: Quorum Technologies

Glow discharge is a popular technique for cleaning and modifying surfaces, especially in TEM sample preparation. The most common treatment is in air glow discharge that results in leaving surfaces hydrophilic and negatively charged.

Could you tell our readers more about the sort of treatments possible with glow discharge?

For the majority of samples, we need hydrophilic surfaces that are negatively charged, as usually molecules or particles dispersed in a water-based solution are charged positively. Such surfaces can be produced by in-air glow discharge treatment.

However, there are situations when we want to have surfaces that are hydrophilic and positively charged. This can be achieved by subjecting in-air glow discharged surfaces to immersion in low percentage water solution of magnesium acetate.

If we use chemical vapor for glow discharge, we can drive the treatment to even higher levels. We can make surfaces hydrophobic and either positively or negatively charged - treatments that are very useful for biomolecules, proteins, antibodies and nucleic acids.

Could you elaborate on the use of glow discharge to support biomolecular research?

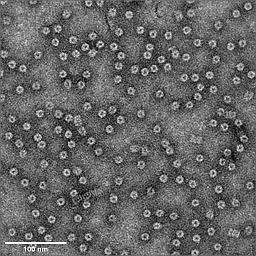

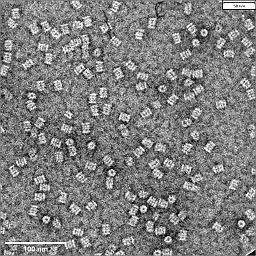

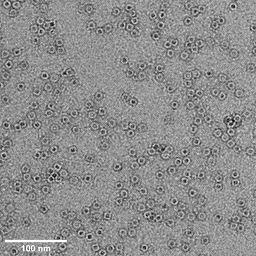

In-chemical vapor glow discharge treatment is very useful for working with proteins, especially if there is a need to model their active centres. A directed orientation of the protein on the TEM grid could be a game changer in the modelling part of the research, as it was in the case of proteasome. The issue with proteasome is that its active centres are located on the sides of the molecule, it was impossible to model them when having a top view of the proteasome molecule. When the surface properties that the proteasome sample was set on were changed, it was possible to achieve majority of side views thus a lot of molecules that could be used for modelling. These special surface properties were achieved by in amylamine glow discharge treatment and render the surface slightly hydrophobic, positively charged and attracted negatively charged sides of proteasome molecule.

Figure 7: (Left, no glow discharge, middle, in-air glow discharge, right, in-amylamine glow.) TEM (Tencai F20) images of 20s human proteasome complex showing the effect of altering the surface charge of the carbon support film on the orientation of the protein molecules. Carbon film of 2.5nm thickness on Quantifoil 1.2/1.3 400 mesh was used as a support for the sample, courtesy of Edward Morris, ICR, London

This in-amylamine treatment has been in use since the 1970s. The first person to use this technique was Jaque Dubouchet, who worked in Paris, France, at the Institute of Cancer Research.

His apparatus was completely manual, whereby a droplet of amylamine was introduced into the glow discharge system using a Teflon valve. This apparatus is still in use today.

Were there any issues with this approach, and how has Quorum Technologies helped to overcome these?

The main problem with Dubouchet’s apparatus is that there is no certainty the treatment will be successful; there may be variation in amylamine pressure or process time due to its manual nature.

We developed the Quorum GloQube system to solve this issue, ensuring that the treatment is fully automatic and there is no need to control the process manually.

Developing an instrument that can automatically control this treatment was challenging for a number of reasons.

Amylamine is toxic and should never be inhaled. The apparatus, therefore, had to be robustly sealed, and it is important to ensure that all amylamine vapor was removed after the treatment before the door could be opened. Furthermore, when exposed to air, amylamine forms enol, which crystallises, clogs instrumentation and prevents the treatment from working.

Quorum Technologies’ GlowQube - glow discharge system has been specifically designed to overcome these issues. Procedures are in place to ensure there is no air in the system and only amylamine is present in the chamber when you run the treatment, and the system is automatically cleaned after using amylamine.

The procedure is safe and can be used to modify surfaces in consecutive runs with no issues.

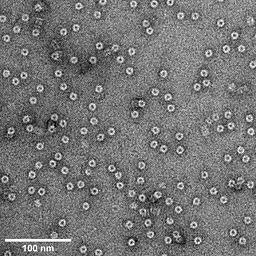

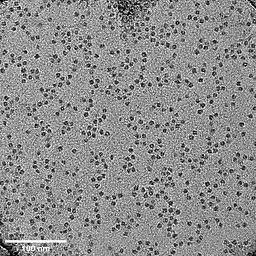

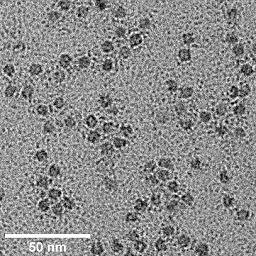

There are also other possible treatments. For example, using methanol as an atmosphere for a glow discharge provides a surface which is negatively charged and hydrophobic. This treatment is useful for working with ferritin, particularly when preparing samples for studying the load of native samples.

Is there any other advice you would give to users beginning to work with glow discharge?

If in-air glow discharge does not provide suitable results, it is always possible to try something else, such as an in-chemical vapor method.

Figure 8: TEM images (Tencai F20 G2) of ferritin protein complex from horse spleen (Sigma Aldrich) applied to in-air and in methanol vapor glow discharged carbon support TEM grids, courtesy of Imperial College London

Many glow discharge systems only include one chamber, meaning it is difficult to run in-chemical vapor glow discharge right after in-air glow discharge without performing a thorough, manual cleaning process first. The GloQube’s cleaning procedure is built-in, making it much easier to try different approaches in short timeframes.

While most of my answers have focused on glow discharge as a treatment for TEM samples, I should point out that a lot of people do use glow discharge for many different purposes; for example, to modify surfaces and to anchor samples for AFM, especially when imaging DNA.

One of the biggest challenges of this method came from its manual and variable nature. It is important to use an automated, reliable system where there is no need to adjust valves or continually attend to the device manually.

Time is money for many processes, and the GloQube is an ideal option for automating this process.

About Dr. Walkiewicz

Dr. Anna E. Walkiewicz is the Applications Specialist at Quorum Technologies. She holds a PhD from the University of Birmingham, where she researched the recognition of chirality at the nanoscale. During her previous role as Applications Scientist for SEM and AFM products at Keysight Technologies, she acknowledged the extreme importance of proper sample preparation for high-resolution imaging. Her main area of interest lies in discovering the outcome of processes occurring at the uppermost part of surfaces.

This information has been sourced, reviewed and adapted from materials provided by Quorum Technologies Ltd.

For more information on this source, please visit Quorum Technologies Ltd.

This information has been sourced, reviewed and adapted from materials provided by Quorum Technologies Ltd.

For more information on this source, please visit Quorum Technologies Ltd.

Disclaimer: The views expressed here are those of the interviewee and do not necessarily represent the views of AZoM.com Limited (T/A) AZoNetwork, the owner and operator of this website. This disclaimer forms part of the Terms and Conditions of use of this website.