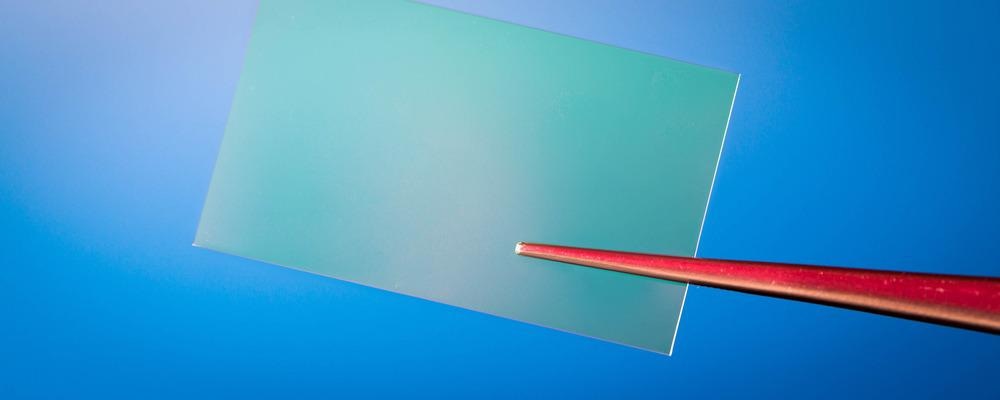

Optical or photonic coatings are generally used to increase the reflection, transmission, or polarization properties of a component, e.g., prisms, polarizing films, color filters, mirrors, diffraction mosaics, and refractory lenses. Photonic coatings are applied in many sectors, such as medicine, sensors, electronics, etc.

Image Credit: luchschenF/Shutterstock.com

Properties of Photonic Coatings

Photonic coatings are based on their optical properties which are applied in electronics and are associated with biomimetic fabrication, surface-enhanced Raman scattering, etc. As stated above, these coatings enhance the reflection, transmission, and polarization properties of components.

A glass component without optical coatings will reflect 4% of incident lights at each surface. On the contrary, a glass with an anti-reflection coating will significantly reduce reflection at each surface to less than 0.1%. A highly reflective dielectric coating can enhance reflectivity to more than 99.99%. Typically, optical coatings are composed of metals, oxides, and rare earth materials. The performance of these coatings is based on the number of layers of coating applied, and its refraction index.

Photonic crystals, also known as photonic band-gap materials, are optical nanostructures that have been developed to impact the motion of photons, similar to how a semiconductor crystal affects the motion of electrons. Photonic crystals are available in nature in many forms and have been extensively studied for the last hundred years.

These crystals are important optical materials that are used to control the flow of light. Photonic crystals are widely used for the development of low and high reflection coatings for lenses and mirrors. They are also used to produce color-changing paints and inks.

Photonic Coatings for Windows

Scientists from the University of California, Berkeley Lab, have developed a polymer heat-reflective photonic coating, which when applied onto windows can improve energy efficiency. This coating contains photonic crystals which can reflect light selectively at different wavelengths. The main advantage of using this coating is that it limits the use of heating systems and air-conditioners.

The polymer heat-reflective photonic coating is based on brush block copolymers that can speedily self-assemble to form photonic crystals. These crystals are easily tunable across the entire spectrum of solar energy. In other words, these photonic nanocrystals can selectively reflect light at different wavelengths.

The molecular architecture of bottlebrush polymer consists of one main rigid chain of molecules with bristles coming off the sides. One of the advantages of this structure is that it does not entangle easily. Raymond Weitekamp, a scientist at the Berkeley Lab, compared the structure of bottlebrush polymers with gummy worms that can be aligned easily and are rigid. In contrast, cooked spaghetti cannot be aligned easily owing to its structure.

Several energy-efficient window coatings are commercially available, which are extremely expensive and require professional contractors for installation. The newly developed product is cost-effective, and at present, they are working on bringing down the cost to $1.50. The low cost will increase consumer usage, which could save annual energy consumption of around 35 billion kilowatt-hours.

Additionally, the application of these coatings onto windows would significantly decrease carbon dioxide emission by 24 billion kilograms per year, which is equivalent to the emission of five million cars.

One of the technological challenges remaining to be addressed by scientists is the enhancement of the fidelity of the photonic coating material. This improvement will enhance the ability of the coating to reflect the majority of the sun’s energy while lowering the amount of heat passing into a building, while still being clear to the eye.

Photonic Coating to Monitor Sensitive Objects

Researchers at the University Academy Holbeach, England, have developed a new photonic coating technology while studying photonic crystals for optical and digital fingerprinting. This coating comprises a visible IR transparent polymer resin that possesses elastomeric diffractive optics properties. This component is chemically stable, insoluble in water, has high plasticity, and is stable at temperatures between 20 and 80oC. These properties are extremely beneficial to developing coatings with photonic signatures.

The newly developed photonic coating could be applied to monitor sensitive objects at proximity or from a longer distance. Scientists explained that the primary coating constituents are transparent in both visible and infrared light. Each photonic crystal of the coating is designed such that the band-gap is controlled over two or more spectral regions.

This coating offers a unique signal that is not naturally occurring, is extremely difficult to fabricate, and is not easily recognizable by unwanted eyes with night vision capability. Put simply, this photonic coating contains a distinct infrared band-gap signature. Scientists are optimistic that this coating could be effectively used for anti-counterfeit detection for money and other commercial tracking applications.

Photonic Coatings for Optical Sensors

Studies have shown that photonic coatings, which are capable of responding to the changes in the surrounding environment, are used profoundly as optical sensors, adaptive camouflage, and information encryption. Recently scientists have developed humidity sensing, color-changing photonic polymer coatings, based on hydrogen-bonded three-dimensional (3D) blue phase liquid crystal networks.

Additionally, the self-assembled character of 3D photonic nanostructures, along with the presence of the rigid covalent bonding between the polymers and substrate surfaces, plays an important role in exhibiting the color changes. This polymer photonic coating possesses vivid structural colors.

Researchers explained that the humidity-driven reversible color changes, across the visible spectrum of light, occur owing to the breaking of the hydrogen bonds and, subsequently, conversion into a hygroscopic polymer coating. This technology could be adapted for developing tailorable 3D photonic nanostructures, which could be used for sensing, display, anticounterfeiting, and biomimetic camouflage.

Photonic Coatings and Industry

The USA is the largest market for optical coatings in the world. Several companies commercially manufacture optical coatings, which are used as window coatings for temperature stability, sensors, electronics, medicine, etc. Helia Photonics is one such company based in Scotland, specializing in manufacturing thin coatings for semiconducting devices, laser facets, etc.

This organization is also deeply involved with industrial and academic research on the development and improvement of photonic coatings.

References and Future Reading

Optical Coating: Materials and Deposition Technology. (2022) [Online] Available at: https://www.photonics.com/Articles/Optical_Coating_Materials_and_Deposition/a25493

Yang, Y. et al.(2021) Bioinspired Color-Changing Photonic Polymer Coatings Based on Three-Dimensional Blue Phase Liquid Crystal Networks. ACS Applied Materials and Interfaces. 13(34). pp. 41102–41111. https://doi.org/10.1021/acsami.1c11711

Heeswijk, van A.P.E. et al. (2018) Well-Adhering, Easily Producible Photonic Reflective Coatings for Plastic Substrates. ACS Applied Materials and Interfaces. 10 (35). pp. 30008–30013.. https://doi.org/10.1021/acsami.8b11583

Du, X. et al. (2015) Water as a colorful ink: transparent, rewritable photonic coatings based on colloidal crystals embedded in chitosan hydrogel. Journal of Materials Chemistry C.3. pp. 3542-3546.

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.