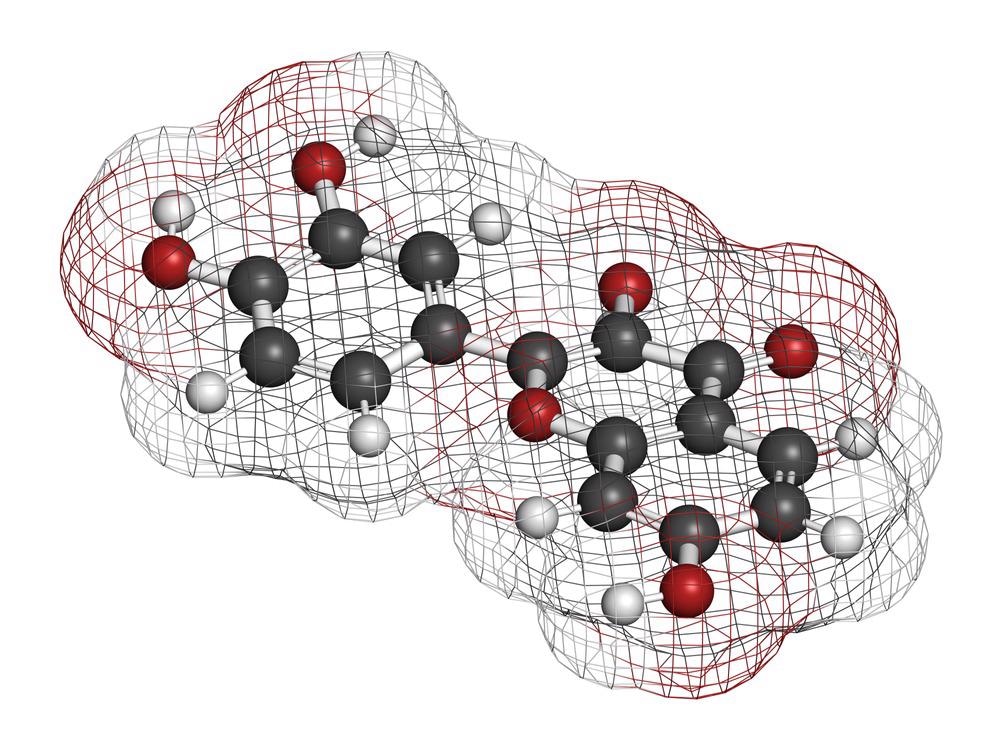

A recent paper in the journal Polymers provides guidelines for designing and synthesizing functional materials for 3D bio-fabrications using polyphenolic materials. Polyphenolic materials are functional materials that have a large number of phenolic groups in their molecular structure.

Image Credit: Wirestock Creators/Shutterstock.com

The demand for organ transplants has increased dramatically due to population growth, industrial accidents, aging, and limited organ donations worldwide. Due to this, the waiting list for organ transplant recipients is increasing rapidly. One of the potential solutions to this problem is the development of artificial organs for a wide range of applications.

Tissue engineering and bioprinting is a promising technology used to develop artificial organs and cells for the human body. Significant research and development are conducted by researchers and industries on biomaterials for tissue engineering. However, they are in a developmental phase and have to overcome a significant number of challenges for practical applications.

One of the challenges in tissue engineering and bioprinting is constructing a three-dimensional (3D) structure from soft materials, which provides a suitable environment for cell growth. Additionally, selecting an appropriate strategy to develop the 3D structure from the soft material is also a technical challenge. It must be noted that the 3D printed soft material should be elastic and fabricated without the negative impact of heat or light source used for chemical reactions.

Phenol Derivatives and Synthetic Polyphenols

Phenol, catechol, and gallol are three major phenol derivatives that are used for bioprinting. The difference between the three is the number of hydroxyl groups on the benzoic site. The main reason for the variation in the three is the molecular structure developed after chemical reactions. Notably, the three phenol derivatives work independently in certain cases.

Synthetic polyphenols are the materials that allow biomaterials to be mechanically transformed into 3D-printed organs and derived from phenol derivatives. They are chemically designed by copying the polyphenol chemistries in nature. Several strategies to design synthesize polyphenolics are suggested in different kinds of literature, and the use of backbone resources is considered significant in the majority of studies.

Backbone materials for polyphenolic materials are protein derivatives or analogs. Some of the backbone materials that can improve the mechanical performance of 3D printed tissues are polyethyleneimine, polyethylene glycol, polyethylene, polyester, epoxy, polypropylene, polytetrafluoroethylene, and polystyrene. Additionally, chitosan is a polysaccharide-based backbone material used to make polyphenolic materials.

Three methods are mainly used to integrate the phenols with the backbone materials that mainly include 1-ethyl-3-(3-dimethyl aminopropyl)carbodiimide/N-hydroxysuccinimide (EDC/NHS) chemical reaction, copolymerization, and self-oxidation. The EDC/NHS method is the most well-adapted method for integrating the phenols with backbone materials.

The primary process in the EDC/NHS method is to incorporate the polymeric material by copolymerization of phenolic monomers. The copolymerization method is also used in specific cases, but its main limitation is that it results in unexpected side reactions. The self-oxidation method is also used in some specific cases to produce faster biofabrication results.

Applications

Polyphenols are used as bio-adhesives that act as a medical sealant for tissues, bones, and muscles. The other applications of polyphenols include functional biocastings in which they act as an interface between biomedical implants and the body. Other than this, they are used for bioprinting, in which bio-ink is 3D printed on a bed surface, which contains appropriate conditions for the cells to grow.

Recent Studies

In a recent study published in the journal Advanced Materials, researchers reviewed the development of biomaterials for biofabrications. They discussed the application of recently developed biomimetic polymers for application in a wide range of medical challenges. They also explored bioprinting at the nanoscale and the development of large-sized organs.

In another study published in the journal Advanced Materials, researchers performed 3D bioprinting of cell-laden hydrogels. The main advantage of the hydrogel was that it provided better control over the cell growth during the printing process and removed limitations such as printing challenges and biocompatibility.

Conclusions

Using a systematic approach to replicate natural polyphenols has a significant scope in bioprinting and tissue engineering. Due to the properties of polyphenols such as crosslinking ability and inherent adhesiveness, a wide range of polyphenolic materials can be developed. The main limitation of the materials is the difficulty of controlling the oxidation of polyphenolics in ambient conditions and the unclear chemical structure of polyphonic materials. This limitation also results in limited commercial applications and inaccurate prediction for in vivo environment applications.

Future studies must focus on studying the basic building blocks of polyphenolics. The studies must also focus on improving the understanding of oxidation and crosslinking mechanisms, and experiments must be conducted to ensure precise on-site control. Furthermore, basic research into the biological responses of polyphenolic materials based on their oxidation states, chemical structures, and environmental conditions should be conducted.

More from AZoM: Analyzing Thin Crystals with an Electron Microscope

References and Further Reading

Han, H.; Lee, K. Systematic Approach to Mimic Phenolic Natural Polymers for Biofabrication. Polymers 2022, 14, https://www.mdpi.com/2073-4360/14/7/1282

Bertassoni, L. E., Bioprinting of Complex Multicellular Organs with Advanced Functionality—Recent Progress and Challenges Ahead. Adv. Mater. 2022, 34, 2101321. https://onlinelibrary.wiley.com/doi/10.1002/adma.202101321

Hull, S. M., Brunel, L. G., Heilshorn, S. C., 3D Bioprinting of Cell-Laden Hydrogels for Improved Biological Functionality. Adv. Mater. 2022, 34, 2103691. https://onlinelibrary.wiley.com/doi/10.1002/adma.202103691

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.