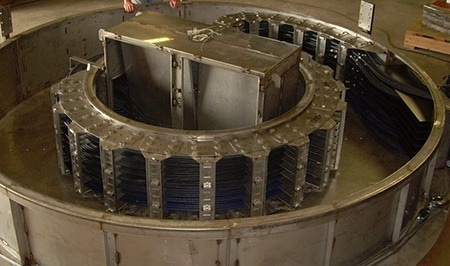

A swing bridge, also known as a pivot bridge or turn bridge, is a low movable bridge that can span long distances. Its primary structural support is often located near the center of gravity along a vertical axis.

Image Credit: Ametek Factory Automation

In its closed position, a swing bridge allows vehicles to cross the waterway. When a ship needs to pass, the bridge rotates approximately 90 degrees to provide clearance. However, the structural support (turntable) creates an obstruction in the waterway, which can limit its use.

These bridges contain multiple electrical cables and hydraulic hoses that control the rotation mechanism. It is essential to protect these components from abrasion, tangling, or twisting during movement. If the cables or hoses become damaged while the bridge is in motion, the operator could lose control, potentially leaving the bridge stuck in an unwanted position.

Solution

Over the years, several engineering firms have used and specified Catrac’s side-mounted, double-radius cable and hose carriers as a rugged, reliable, custom-built solution for bridge applications.

These bridges contain multiple electrical cables and hydraulic hoses that must rotate as the bridge opens and closes.

AMETEK’s steel Catrac includes glide bars, transfer balls, specific magnets, removable stiffeners, adjustable or welded dividers, specialized mounting feet, and optional hold-down clips (for track and drums). It features bolted and stainless-steel construction. Custom enclosures for cable and hose carriers are available upon request.

Image Credit: Ametek Factory Automation

Benefits

These Catrac cable and hose carriers are custom-made to fit specific inner and outer drum diameters.

They provide separation and organization for cables and hoses to prevent abrasion, wear, and twisting. The center pivot design enables smooth cycling, with track components that can be replaced in the field. All units are built with durable, heavy-duty steel construction.

Catrac cable and hose carriers are proudly designed, fabricated, and built in the United States of America.

Conclusion

AMETEK Factory Automation has over 50 years of expertise in developing and producing specialized Catracs for demanding applications, including bridges, steel mills, deicing machines, aerial lifts, directional drilling machines, and stacker reclaimers. It can supply complete systems or spare parts as needed.

Contact AMETEK’s application engineers for more information or to discuss your specific requirements in detail.

This information has been sourced, reviewed and adapted from materials provided by Ametek Factory Automation.

For more information on this source, please visit Ametek Factory Automation.