The Thermo Scientific™ MAX-iR™ FTIR Gas Analyzer has been engineered to meet the most demanding standards for in-line process, batch sampling, gas purity/certification, emissions testing, and ambient air monitoring. Combined with Thermo Scientific™ StarBoost™ Enhanced Optical Technology, the MAX-iR™ analyzer enables users to achieve single-digit ppb detection limits for many applications. For ultra-high purity bulk gas applications, the detection limits can be reduced to mid ppt, making the MAX-iR analyzer one of the most sensitive FTIR gas analyzers ever produced!

The MAX-iR analyzer is controlled by high-performance analytical software specifically developed for real-time process and CEM environments. Fully automated method control, DCS data output, alarm controls, remote access, and reporting tools are all designed to maximize productivity without human interaction. Combined with our standard application-specific multi-channel gas handling panels, the MAX-iR easily goes from being a stand-alone analyzer to a fully automated solution.

Let the MAX-iR analyzer reinvent how to solve your most demanding challenges in process gas analysis.

Variety of Configurations

The MAX-iR gas analyzer is based on a tiny, rugged, high-throughput interferometer with an embedded 24-bit analog to digital (ADC) detector modules that provide excellent signal-to-noise without the use of liquid nitrogen. A long-life vertical cavity surface-emitting laser (VCSEL) diode and a silicon carbide (SiC) IR source have boosted the analyzer’s longevity and dependability.

For the most demanding certification operations, incorporated temperature and pressure sensors give enhanced accuracy. Lastly, the analyzer’s dual-level vibrational dampening enables it to function even under harsh field conditions.

The MAX-iR analyzer includes a deuterated triglycine sulfate (DTGS) detector as standard. Users can choose between indium arsenide (InAs) and mercury-cadmium-telluride (MCT) detectors with the additional StarBoost technology.

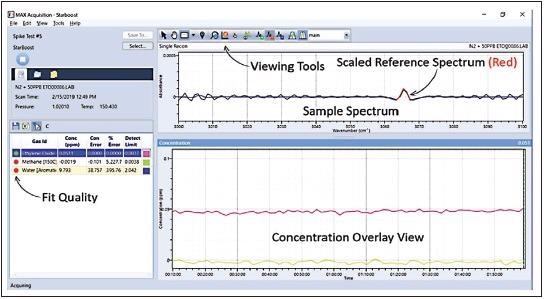

Thermo ScientificTM MAX-AcquisitionTM Automation Software and MAX-AnalyticsTM Software come as standard on all systems, providing industry-leading analytics, factory integration tools, elevated compound identification, and measurement precision without the need for calibration.

MAX-iR FTIR gas analzyer. Image Credit: Thermo Fisher Scientific – Materials & Structural Analysis

Features and Benefits

- 10 m high throughput multipass gas cell

- Precision temperature and pressure sensors

- 1–32 cm-1 resolution FTIR spectrometer

- 5U–19-inch standard rack

- Real-time gas analysis (1 second to 1-minute response)

- VCSEL diode (10-year lifetime)

- SiC IR source (10-year lifetime)

- Non-hygroscopic optics (no purge required)

Options

- Analysis methods (factory-supplied)

- StarBoost technology upgrade

- DTGS detector with standard system, InAs or MCT detectors with StarBoost

Typical Applications

- Inline process monitoring

- Ambient air testing

- Leak detection

- Gas certification analysis

- Gas purity analysis

- Continuous emissions monitoring (CEM)

- Stationary source testing (RICE, turbines, cement kiln)

The back and inside of the MAX-iR FTIR gas analyzer. Image Credit: Thermo Fisher Scientific – Materials & Structural Analysis

MAX-iR Analyzer Specifications

- 75 lbs

- 19 × 24 × 8.75-inch rack mount

- 120/240 VAC 50/60 Hz

- Incorporated temperature and pressure sensors

- Industry-leading FTIR spectrometer

- SiC IR source

- ZnSe optics

- VCSEL diode laser

- Environmental temperature: 20–30 °C

- Environmental humidity: 10–90% RH, non-condensing

- Operating temperature: 5–191 °C

- N2 purge port (usage optional)

- Single 1/4” Swagelok™ input/output

- 10 m pathlength—0.5 L volume standard

MAX-Acquisition Software

- Real-time quantitative analysis

- FTIR configuration and control

- Thermo Scientific™ MAX-OXT Thermal Oxidizer Module control

- Thermo Scientific™ MAX-INT Factory Interface Module

- Thermo Scientific™ ASC-10™ automated sampling console control

- Automated sample collection workflow

- Modbus™ TCP/IP communications

MAX-Acquisition software screen. Image Credit: Thermo Fisher Scientific – Materials & Structural Analysis

MAX-Analytics Software

- Compound search

- Data validation and analysis

Optional Hardware

- Windows BaF₂, KBr, CaF₂, ZnSe

- Operating pressure: 1 or 5 atm

- Detector

- DTGS (standard)

- TE-cooled InAs (StarBoost)

- TE-cooled MCT (StarBoost)

- StarBoost optical enhancement technology

Accessories

- MAX-INT factory interface module

- MAX-OXT thermal oxidizer module

- ASC-10 automated sampling console

Video credit: Thermo Fisher Scientific