Harvard University researchers have discovered a novel technology that prevents development of ice or frost on metal surfaces. Any formation of ice can slide off the treated surface. The technology may have potential applications in aircraft, wind turbines, refrigeration systems and other industries.

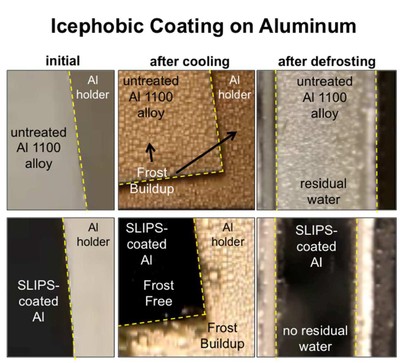

A scalable method to directly coat aluminum surface with nanostructured polymer layer subsequently converted into a slippery liquid-infused porous surface (SLIPS) is demonstrated. SLIPS can effectively delay ice accumulation and facilitate removal of ice even under high humidity conditions.

A scalable method to directly coat aluminum surface with nanostructured polymer layer subsequently converted into a slippery liquid-infused porous surface (SLIPS) is demonstrated. SLIPS can effectively delay ice accumulation and facilitate removal of ice even under high humidity conditions.

The water repellent properties of the lotus leaf had inspired a research group to create an ice-repellent surface. The Amy Smith Berylson Professor of Materials Science at the Harvard School of Engineering and Applied Sciences (SEAS) and a member at the Wyss Institute for Biologically Inspired Engineering, Joanna Aizenberg led the research group. Under conditions of high humidity, this technique may not work, as frost and condensation get coated on the surface textures.

The research group invented the Slippery Liquid Infused Porous Surfaces (SLIPS) technology that exposes a molecularly flat liquid interface, devoid of defects. A hidden nanostructured solid immobilizes the interface. This helps address extreme pressure and high humidity conditions. Frost, solid ice, condensation and frost can easily slide off the surface.

The team developed a method to coat a rough material on to metal surfaces, on which the lubricant may stick on. This coating is anti-corrosive and non-toxic. The technology was applied on to refrigerator cooling fins and tested under deep freeze conditions. The frost-free effect lasted for a longer time when compared to existing systems.

The SLIPS technology reduces energy costs as it prevents ice formation at low temperatures. When this coating is applied onto wind turbines, wires, signs, and roofs the ice formed on them can be easily removed through vibration, agitation and wind.

The study was published online in ACS Nano.