LPW Technology Ltd, a market leader in the development and supply of optimised metal powders for additive manufacturing (AM), will present new research on powder re-use at RAPID 2014 (Detroit, 9-12th June).

Meet LPW Technology at RAPID 2014 for expert input on powder characterisation

Meet LPW Technology at RAPID 2014 for expert input on powder characterisation

RAPID is an industry-leading forum for discussion of the latest advances in 3D printing, additive manufacturing, rapid technologies and 3D scanning. In his presentation ‘Quality control measures critical to the adoption of sustainable Additive Manufacturing component production’, Mr Hunter will highlight the analytical techniques that can be used to assess the suitability of metal powders for AM applications and recycling. LPW Technology will also exhibit LPW PowderSolve, the company’s innovative software solution for powder lifecycle management on the company’s booth #1521.

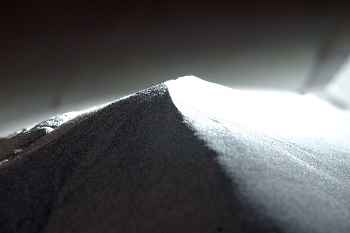

Understanding the behaviour of metal powders in AM machines is vital for the precisely controlled production of sophisticated, functional components. Identifying which powder properties control AM performance supports both the optimisation of metal powders for specific applications and the reliable evaluation of used powders for further processing. Powder recycling is essential for the long-term sustainability of the industry.

Mr Hunter’s talk will focus on new research that assesses the impact of two alternative AM technologies on the mechanical and metallurgical properties of metal powders, Selective Laser Melting and Laser Metal Deposition. The experiments elucidate how processing changes metal powders, an essential step in assessing the feasibility of recycling. The analytical data from this work will also be used to demonstrate a novel software solution for powder management, LPW PowderSolve. This package can be used to maintain traceability, document powder aging, and highlight contamination prior to powder use, thereby ensuring the highest levels of quality control, throughout the lifecycle of the powder.

LPW Technology is a global supplier of certified AM powders and lead the way in characterising and optimising powders for specific machines or applications. The company has developed a full range of optimised powders specifically for Selective Laser Melting (SLM), Laser

Metal Deposition (LMD) and Electron Beam Melting (EBM) with standard powders supplied from stock, and custom and development alloys available on request. To discuss any aspect of AM metal powder performance with experts from company visit booth #1521.