An electrolyte has recently been developed for lithium batteries which can remove these dendrites. At the same time the electrolyte can make batteries far more efficient by allowing them to carry a considerable amount of electrical current. Batteries that use other dendrite-restricting solutions have failed to sustain current densities and high efficiencies. The study has been published in Nature Communications.

A large number of rechargeable lithium-ion batteries are being used nowadays and they include two electrodes: positively charged and negatively charged. The former contains lithium, while the latter is made of graphite. When electrons pass through a wire which links the two electrodes, electricity is produced.

Our new electrolyte helps lithium batteries be more than 99 percent efficient and enables them to carry more than ten times more electric current per area than previous technologies. This new discovery could kick-start the development of powerful and practical next-generation rechargeable batteries such as lithium-sulfur, lithium-air and lithium-metal batteries.

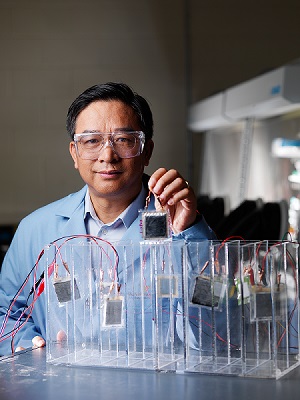

Ji-Guang Zhang - Physicist

Department of Energy's Pacific Northwest National Laboratory

In order to control the electrons, positively charged lithium atoms move from one electrode to the other via another path, i.e., the electrolyte solution on which the electrodes are located. However, graphite is characterized by a low energy storage capacity and thus restricts the quantity of energy a lithium-ion battery can provide electric vehicles and smart phones.

Earlier in the 1970s, when lithium-based rechargeable batteries were initially created, scientists used lithium for the negative electrode - the anode. When compared to graphite, lithium has 10x more energy storage capacity. However, a major drawback was that the lithium-carrying electrolyte reacts with the lithium anode and this in turn caused tiny lithium dendrites to grow resulting in battery failures.

PNNL physicist Jason Zhang and his colleagues have developed a new electrolyte for the elimination of short-circuiting dendrites in rechargeable batteries.

PNNL physicist Jason Zhang and his colleagues have developed a new electrolyte for the elimination of short-circuiting dendrites in rechargeable batteries.

Over the years, numerous attempts were made to tweak the rechargeable batteries to overcome the dendrite issue. Later, in the early 1990s, other materials such as graphite were used for the anode. Recently, researchers have used a protective layer on the anode, while others have developed electrolyte additives. While some solutions were able to remove dendrites, they also gave way to impractical batteries with minimum power. Although other techniques slowed the fiber's growth, they did not stop them altogether.

PNNL re-examined the older designs, assuming that present-day rechargeable lithium-ion batteries having graphite anodes may be close to their peak energy capacity. To that end, Zhang and his team developed an electrolyte that worked efficiently in batteries having a high-capacity lithium anode.

The researchers also noted that others had some amount of success with electrolytes having high salt concentrations and ultimately opted to use large amounts of the lithium bis(fluorosulfonyl)imide salt. In order to develop the electrolyte, they added the salt to dimethoxyethane, a kind of solvent. They later built a circular test cell.

A lithium anode and the new electrolyte were then used in this test cell. Rather than growing dendrites, the anode produced a thin, smooth layer of lithium nodules, which did not short-circuit the battery.

Following 1,000 repeated charge and discharge cycles, the circular test cell effectively retained 98.4% of its initial energy while carrying 4mA of electrical current per square centimeter of area. The researchers discovered that higher current densities lead to slightly lower efficiencies.

For instance, for a current density of 10mA/cm2, the test cell retained an efficiency of greater than 97%. Similarly, a test cell carrying only 0.2mA/cm2 acquired as high as 99.1% efficiency. Majority of batteries with lithium anodes work at a current density of 1mA/cm2 or less, and do not work after 300 cycles.

According to Zhang, the high efficiency of the new electrolyte could pave the way for an anode-free battery. The negative electrodes used in present-day batteries contain thin metal pieces such as copper, which is coated in lithium, graphite, or similar active materials. These thin metal bases are known as current collectors, as they maintain the electron flow to power the smart phones.

Active materials were used to coat the electrodes, as most electrolytes have not been efficient and use lithium ions during battery usage. However, an electrolyte with over 99% efficiency offers a possibility to design a battery that only includes a negative current collector, sans having an active material coating on the anode side.

Not needing an anode could lower the cost and size of rechargeable batteries and would also significantly improve the safety of these batteries, Zhang added.

However, more research is needed to refine the new electrolyte before it can be used in mainstream applications. Zhang and his team are examining a wide range of additives to improve their electrolyte, so that a lithium battery using it can acquire over 99.9% efficiency, a level that is required for commercial use. The research team is also evaluating which cathode materials would operate best in tandem with the new electrolyte.

In order to test the performance of the battery material, the team applied sophisticated methods such as X-ray photoelectron spectroscopy and scanning electron microscopy at the Environmental Molecular Sciences Laboratory (EMSL), a DOE Office of Science national user facility at PNNL. It also carried out molecular dynamic simulations in association with the Army Research Laboratory.

The study was funded by the Joint Center for Energy Storage Research (JCESR) through DOE's Office of Science.