Sep 4 2015

Self-cleaning windows, stain-resistant automobile interiors, graffiti-proof walls—there is a long list of things that we wish could have a surface to which dirt wouldn’t stick. In the journal Angewandte Chemie, Canadian scientists have now introduced a new method for producing transparent, smudge-resistant coatings resistant to both water- and oil-soluble contaminants. In contrast to previous approaches, this method does not use fluorinated substances, which makes the coatings both significantly less expensive and more environmentally friendly.

Previous methods for making smudge-resistant coatings have not been widely applicable because they lacked the necessary transparency and wear resistance. Fluorine-containing substances that do have the right properties are too expensive for widespread use. In addition, fluorine-containing products cause environmental problems because they do not degrade and bioaccumulate.

The new approach developed by a team from Queen’s University (Kingston, Ontario, Canada) headed by Guojun Liu is fluorine-free and based on polyurethane, an inexpensive type of plastic that adheres well to a wide variety of surfaces. The novel coatings remain clear at layer thicknesses of tens of micrometers. They repel both aqueous and oily contaminants.

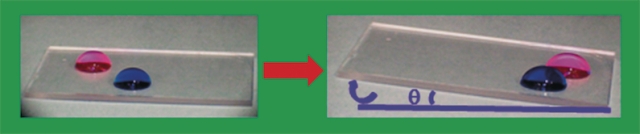

The success of this new coating stems from grafted side chains made of poly(dimethylsiloxane) (PDMS), a biocompatible silicone oil used in medicine. The individual components and the conditions for the synthesis were chosen to produce a highly cross-linked polyurethane matrix in which nanodomains of PDMS are embedded. At the surface, the silicone side chains form a thin lubricating liquid film. When another liquid such as cooking oil is dispensed on the surface, the liquid readily slips off because the lubricating thin liquid film, unlike a solid surface, cannot grab the liquid.

The new coatings repel ink, artificial fingerprints, and paint. They maintain their anti-smudge properties after being scratched with sandpaper. The researchers attribute this resiliency to the fact that after damage occurs, fresh PDMS side chains rise out of the nanodomains to the new surface, regenerating the damaged PDMS layer.

Possible applications include coatings for touchscreens of mobile telephones and other portable electronic devices, as well as anti-graffiti coatings.