When the band-aid stretches are applied to flexible areas, like knee or elbow, the embedded electronics remain intact and functional. The hydrogel matrix, a rubbery material consisting mostly of water, is the main component of the stretchable band-aid which is designed to strongly bond with gold, aluminum, titanium, glass ceramics and silicon.

A strong and stretchy bond

In general synthetic hydrogels tend to be tough and rigid, making them difficult to be stretched, and are brittle with weak bonding towards other surfaces.

They’re often used as degradable biomaterials at the current stage. If you want to make an electronic device out of hydrogels, you need to think of long-term stability of the hydrogels and interfaces.

Xuanhe Zhao - MIT

The team at MIT developed a new, robust hydrogel design. The novel hydrogel was created by mixing water with minute quantities of specific biopolymers, which resulted in a soft, stretchy material which had a stiffness ranging from 10 to100 kPa. This stiffness is equivalent to the stiffness of human tissue. The newly developed material was also capable of strongly bonding with several nonporous surfaces.

Various applications of the hydrogel were illustrated by the team through different techniques. These included the encapsulation of a titanium wire which could then be used as a stretchable, transparent conductor. It was found that despite repeated stretching of the titanium wire its electrical conductivity remained constant.

Another test carried out by the team was the embedding of an array of LED lights into a sheet of the hydrogel. It was observed that the array remained functional even when the sheet was fastened to various parts of the body and stretched across highly flexible joints like the knees and elbows.

A versatile matrix

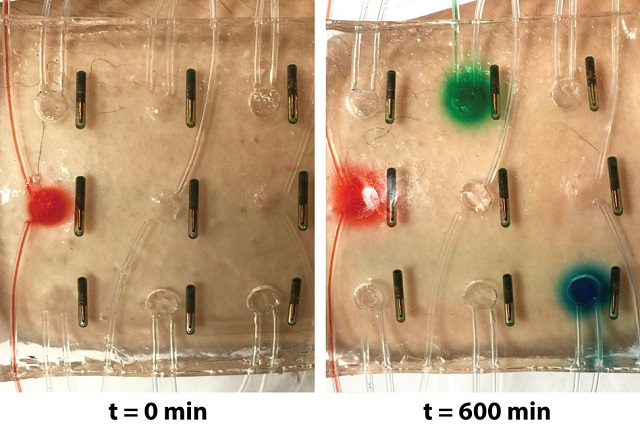

The team then proceeded to embed multiple electronic components within the hydrogel to create a ‘smart wound dressing’ that consisted of temperature sensors placed at regular intervals with small drug reservoirs embedded within it. Pathways, which are for the facilitation of drug flow, were created within the hydrogel by inserting patterned tubes or by drilling tiny holes through the matrix.

Drugs can be released at specific locations on demand based on the temperature of the skin at that location

The team determined that when the dressing was placed over the body and subjected to stretching, it continued to monitor skin temperature and release drugs as instructed by the sensor's readings. This technology could be immediately used as a flexible, on-demand treatment for burn wounds or other skin conditions.

It’s a very versatile matrix. The unique capability here is, when a sensor senses something different, like an abnormal increase in temperature, the device can on demand release drugs to that specific location and select a specific drug from one of the reservoirs, which can diffuse in the hydrogel matrix for sustained release over time.

Hyunwoo Yuk - MIT

The hydrogel could be used as a biocompatible delivery vehicle for embedding electronics, such as glucose sensors, in the body. When traditional glucose sensors are implanted in the body they evoke a foreign-body response from the immune system which results in the sensor being covered in dense fibers. This immune response rapidly renders the sensor as inactive, meaning they must be regularaly replaced.

Historically hydrogels have been used to coat glucose sensors in order to mitigate the immune response however they are very brittle and easily detached during motion. The newly developed hydrogel-sensor system promises to bypass these problems and also shows the potential to also be used in neural probes.

The brain is a bowl of Jell-O. Currently, researchers are trying different soft materials to achieve long-term biocompatibility of neural devices. With collaborators, we are proposing to use robust hydrogel as an ideal material for neural devices, because the hydrogel can be designed to possess similar mechanical and physiological properties as the brain.

Xuanhe Zhao - MIT

The research has been published in the journal Advanced Materials.