With RocTool high heat molding, the level of the tool surface replication goes up to 97.2%, providing product designers very premium looks, high gloss possibilities and matching the texture they initially targeted.

The flow increase with RocTool high heat molding technology unlocks design rules and pushes the limits in order to create thin wall applications. RocTool has implemented a materials database, which will continue to grow every month, every year as materials are qualified: “We are currently selecting many resins from different resin providers and testing key factors such as overall surface quality, level of replication of the tool surface, weld line strength, flow length… qualifying the results between parts produced by conventional injection molding methods versus RocTool molding technologies.

We can clearly see when the overall quality reaches a High Definition level from a visual aspect, but also from a performance aspect”, Mathieu Boulanger, RocTool CEO explains. RocTool is currently analyzing samples to evaluate the level of replication that can be reached from a standard tool texture to a micro replication.

Working with Resin providers, Compounders and innovators in the plastic industry

HD Plastics™ is not only targeting commodity resins but also high-performance resins and ultra-polymers. The ability to reach high temperatures before injection, extends the process window and molding possibilities for performance materials such as PEEK, PEI and those with high filler content.

With HD Plastics™, RocTool is aiming to offer more part performance, light weighting and top surface quality. “Those are the main drivers and we are collaborating with companies in the plastic industry to exploit the possibilities of HD Plastics™ to reach a new level of quality that is now possible”. Mathieu continues.

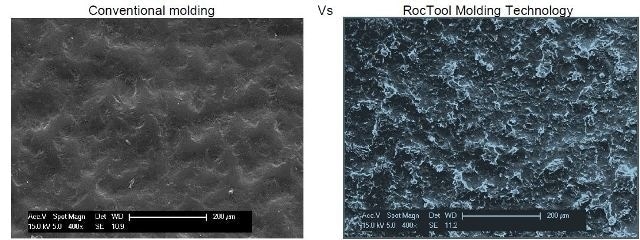

SEM Micrography of Chemical Grain Surface – (Polycarbonate)

The left side shows a texture obtained with conventional injection molding, then on the right it is the same texture and same material but with very detailed replication using RocTool molding technology (picture 400X magnification).

The left side shows a texture obtained with conventional injection molding, then on the right it is the same texture and same material but with very detailed replication using RocTool molding technology (picture 400X magnification).

Planet friendly and No paint is a priority

With HD Plastics™, RocTool is currently evaluating all the possible solutions to reduce or eliminate the use of paint. The use of the right resins with RocTool process and creating unique decorated textures on the tool surface is a way to fully eliminate secondary operations. “We realize that increasing the number of painting lines, or adding secondary steps in the manufacturing of decorated products is not a long term solution, along with the need to be environmentally concerned. The use of decorative film is also costly and very difficult to use on complex shapes.” Dr. Feigenblum, RocTool CTO adds.

Scratch resistance on a plastic molded part is clearly a challenge, but the selection of the right resins, colors, extended process window with RocTool induction system and the unique tool surface patterns are efficient ways to address it and find good compromises.

HD Stories

In order to inspire and work with product designers, RocTool will frequently release some “HD Stories” to share some quality achievements on real products in production, such as NESPRESSO® who recently won the JEC Innovation Award in partnership with RocTool and Flex for their Pixie Clips coffee machine.