May 3 2016

Hudson, MA, May 2, 2016 – SignalFire Wireless Telemetry offers a Chemical Injection Monitoring and Control Package that provides control, operational visibility and diagnostic system monitoring capabilities over the chemical injection process for optimized results at lowest cost functionality.

As simple timers offer little or no operator visibility over the chemical injection processes, chemical dosage into a well can be inaccurate, resulting in over expenditures of tens of thousands of dollars annually, not to mention premature reworks. The SignalFire Chemical Injection Monitoring and Control Package enables closed-loop control of the tank pump for precise daily dosage while providing operational visibility into tank levels, temperature and pump status for early detection of issues such as if the tank requires refilling.

An auto volume operating mode allows operators to specify chemical dosage at an hourly volume while an auto production mode automatically calibrates and monitors pump operation to maintain a specified injection rate that may be slaved to production rates. As chemicals follow different dosing protocols, the SignalFire Chemical Injection Monitoring and Control Package maintains the appropriate dosage frequency at the desired flow rate based on changing well conditions. And if the well shuts-in, the pump will stop injecting expensive chemicals into the well.

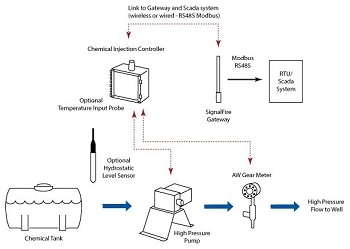

Integrating into an existing tank, pump and electrical system configuration, the SignalFire Chemical Injection Monitoring and Control Package utilizes a PD flow meter attached to a high-pressure pump to interface remotely with a chemical tank to verify that chemical injection is working to specification and report data to a chemical injection controller. The addition of a PD flow meter to the package was a strategic decision to improve the system’s accuracy and repeatability.

Replacing unreliable timers with the SignalFire Chemical Injection Monitoring and Control Package offers more precise control over injection for greater product quality while eliminating waste due to over-injection and optimizing well performance by avoiding over injection. Operators can remotely monitor and control parameters and conditions at the injection site from the chemical injection controller using as part of a SignalFire Telemetry Remote Monitoring and Control System utilizing a Gateway network for a complete wireless pad automation. Using the optional wireless system eliminates the need to run a wire from the SCADA to the injection site and is less expensive than 75 ft. of the conduit.

For more information on the SignalFire Chemical Injection Monitoring and Control Package, refer to the website: http://www.signal-fire.com/products/chemical-injection-system/ or contact the company at 978-212-2868 or [email protected].