May 4 2016

With documented public water issues caused by corrosion in Hoosick Falls, New York, and Flint, Michigan, it is necessary to know the impact of corrosion on copper at the atomic level so that such issues can be avoided in future pipes. Corrosion-related damage costs represent 3% of the US Gross Domestic Product (roughly $503.1 billion, as per the values in 2013).

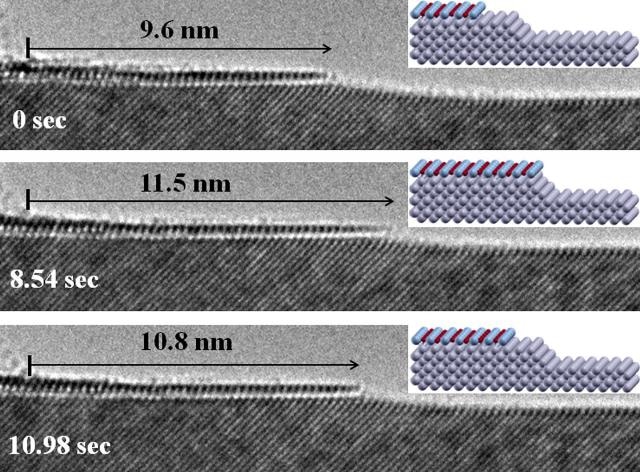

This is an in-situ atomic-scale observation of the oxidation process of a copper surface by transmission electron microscopy. (credit: Guangwen Zhou)

This is an in-situ atomic-scale observation of the oxidation process of a copper surface by transmission electron microscopy. (credit: Guangwen Zhou)

Copper is the main building material used in water piping. The oxidation of copper was observed at the atomic level by Binghamton University researchers using sophisticated in situ microscopy methods. They observed the process as it was occurring. The study results could help to develop pipes with improved corrosion resistance.

Oxidation of metals [the loss of electrons at the molecular or atomic level] is a universal reaction caused by the simple fact that the oxide of most metals is more stable than the metal itself. Resistance to corrosion or oxidation is one of the most important properties for materials exposed to air or water.

Because water is naturally corrosive, especially for pipes carrying hot water, where the elevated temperature accelerates the oxidation/corrosion rates, the Environmental Protection Agency (EPA) requires all water systems monitored for the levels of copper. The most common reason for water utilities to add corrosion inhibitors is to avoid copper corrosion. The research findings of our study on the oxidation of copper alloys can facilitate the development of new alloys with improved resistance to corrosion in water.

Guangwen Zhou, Associate Professor, Mechanical Engineering, Binghamton University

The study results will not only help to develop better water pipes, but it will also provide insights into retaining material stability in nanoscale devices that are employed in medical science and energy. The use of atomic-resolution electron microscopes enabled the researchers to discover that copper oxidation takes place through the layer-to-island growth of copper oxide on the surfaces of flat copper, with the evaporation of copper atoms from the surface.

They also observed the deposition of solid oxide, composed of oxygen and copper atoms that are thermally mixing above the original surface microscopically, back on the surface. This finding contradicts the long-held theory of a solid-solid transformation. This information is counterintuitive as it shows that a surface can exhibit better oxidation resistance if it is more uneven.

Recent advances in instrumentation have made it possible to investigate the oxidation of metals exposed to oxygen gas and elevated temperature with in situ measurements. Employment of these techniques can provide unique opportunities to establish the principles of controlling atomic processes of surface oxidation. Using these tools, we are able to gain unprecedented insight into the oxidation mechanism of copper and copper alloys.

(Oxidation) can lead to the formation of a protective layer against corrosion attack. Our results establish the principles of predicting the trend for promoting or suppressing the oxidation of materials, which is much needed for smarter utilization to steer the reaction toward the desired direction for real applications such as corrosion resistance or improved chemical catalysis.

Guangwen Zhou, Associate Professor, Mechanical Engineering, Binghamton University