Apr 5 2017

CREDIT: ILLUSTRATION BY CRAIG FENNEL, EGRAFX, AND CHUAN-HUA CHEN. DUKE UNIVERSITY

CREDIT: ILLUSTRATION BY CRAIG FENNEL, EGRAFX, AND CHUAN-HUA CHEN. DUKE UNIVERSITY

Duke University researchers have developed new 'jumping droplet' technique which passively cools dynamic hotspots with effective thermal transport in all directions.

The constraints of the performance of electronic devices are their inability to uniformly dissipate the waste heat they produce. Hotspots are widespread in electronics as the waste heat isn't uniformly distributed. A few options for hotspot cooling do exist, however the performance of these options are found to be lacking for mobile hotspots. This is a result of the fact that mobile hotspots move according to ever-changing computing tasks or power-amplification demands.

That's about to change because of he work of researchers from Intel Corp and Duke University. These researchers report a "jumping droplet" technique designed specifically to address mobile hotspots in the cover article appearing this week in the journal Applied Physics Letters, from AIP Publishing.

This technique is based on a discovery made in the lab of Alfred M. Hunt Faculty Scholar in the Department of Mechanical Engineering and Materials Science and associate professor Chuan-Hua Chen at Duke University.

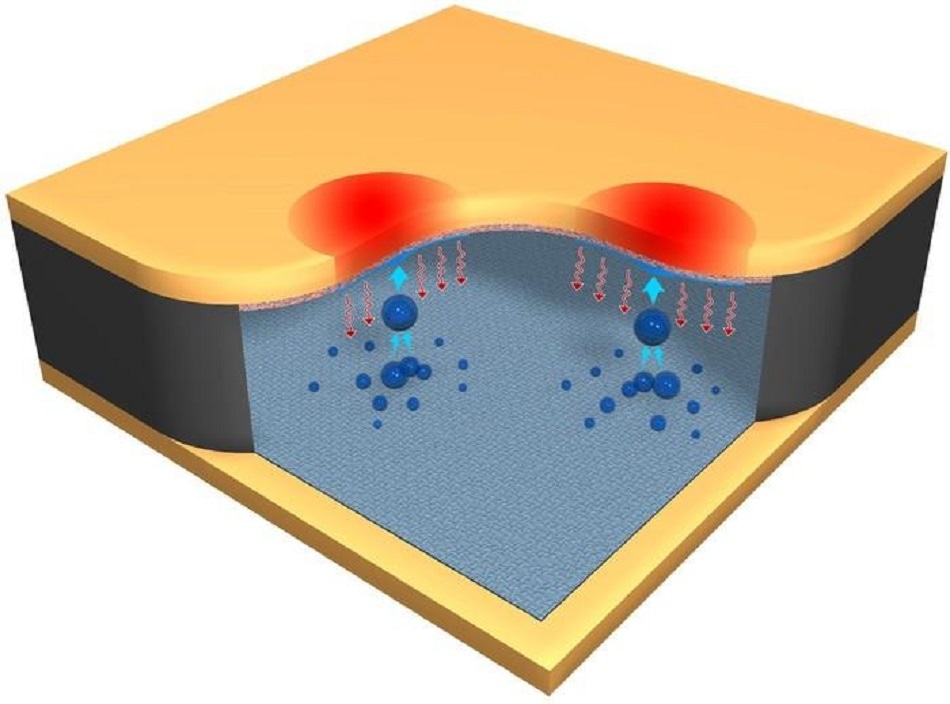

Chen's team discovered that when two water droplets merge together on a water-repellant (superhydrophobic) surface, the resulting merged droplet spontaneously jumps perpendicular to that surface. They further found that the jumping motion, which is out-of-plane, is driven by surface energy initially stored on the droplets and upon drop coalescence is released. This effect can locally cool hot spots, which they demonstrated in a vapor chamber.

Two parallel plates: a superhydrophobic surface and a sponge-like (superhydrophilic) surface, are what the jumping droplet vapor chamber consists of.

When a hotspot appears on the superhydrophilic surface saturated with water, it drives the working fluid to vaporize. The water vapor condenses on the opposing superhydrophobic surface, and rejects the waste heat. As condensate droplets grow and merge, the coalescence-induced jumping motion returns the working fluid back to the superhydrophilic surface. This 'jumping return' enables continuous operation of the vapor chamber to dissipate heat.

Chuan-Hua Chen, Associate Professor, Duke University

Chen states that the primary advantage of the jumping droplet technique is; "its mechanism to perpendicularly return the working fluid to the hotspots, and because jumping droplets are driven by intrinsic surface energy, the technique is independent of external forces and gravitational orientation."

This advance is significant because hotspot-cooling techniques used today aren't very effective for mobile hotspots. "Thermoelectric cooling, for example, is best for a fixed hotspot location. And electrowetting requires external power input," Chen said. Much like flat-plate heat pipes, the team's jumping droplet technique cools mobile hotspots without the require any active power input.

The removal of heat through horizontal spreading in flat-plate heat pipes are remarkable, they are much more effective than diamond heat sinks or even high thermal conductivity copper. However, they lack a vertical mechanism to dissipate heat.

Our technique not only retains the high effectiveness of flat-plate heat pipes for in-plane heat spreading, but also provides a much better capability for out-of-plane heat transport because of the perpendicular jumping mechanism.

Chuan-Hua Chen, Associate Professor, Duke University

The combination of horizontal and vertical spreading is ideal for heat dissipation. As an analogy: "to avoid flooding, it's useful to spread the rain horizontally over a large area. But if the ground becomes soaked and water has no vertical pathway to escape, flooding is inevitable," Chen said. "Our jumping droplet technology addresses this technological void with a vertical heat spreading mechanism, opening the door to outperforming the best solid heat spreaders in all directions."

This new method could provide longer lifetimes and quicker computing for electronics because the performance of power electronics and computers rely heavily on heat waste disposal capabilities. To best exploit their new technique, the team view be looking at material choices as their next goal.

It's technically challenging to design a jumping droplet vapor chamber with materials of opposite wettability that are compatible with high-temperature vapor. We'll fine-tune material choices so that our system can stably work at higher temperature with more effective heat dissipation. We've already demonstrated a cooling performance comparable to copper, but I see a pathway to significantly exceed this industrial standard once we sort out the material issue.

Chuan-Hua Chen, Associate Professor, Duke University

The article, "Hotspot cooling with jumping-drop vapor chambers," appeared in the journal Applied Physics Letters April 3, 2017