Dec 14 2017

A new and potentially innovative material with the ability to considerably minimize the energy consumption and emissions related to the synthesis of ethylene has been developed by researchers from ExxonMobil and the Institute of Chemical Technology (ITQ), a joint research center of Valencia’s Polytechnic University and the Spanish National Research Council (CSIC).

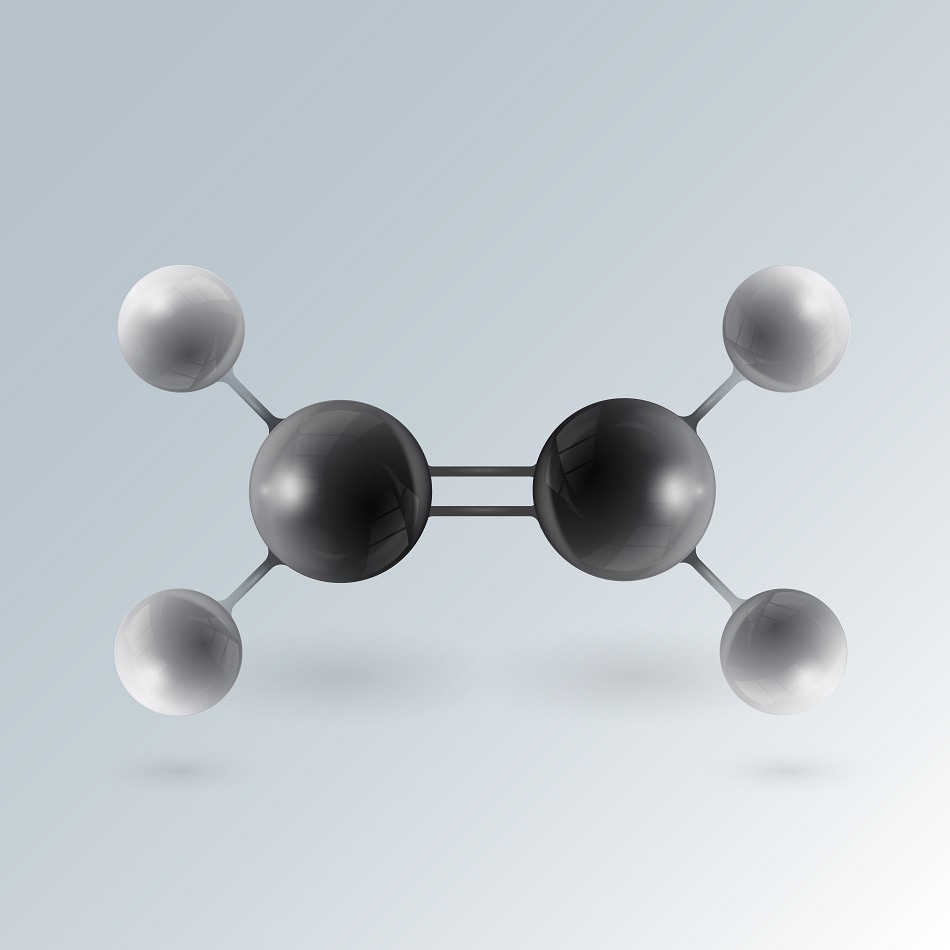

Tonov/ Shutterstock.com

Tonov/ Shutterstock.com

The innovative material, together with other separation procedures, can result in nearly a 25% reduction in the amount of energy needed at present for separating ethylene, and also the related carbon dioxide emissions. The outcomes of the study have been published in the Science magazine.

Scientists from ExxonMobil and the ITQ have found out that the innovative material, which is formed of a silica zeolite with a distinctive structure, can be adopted for gas separation techniques, for example, retrieving ethylene from currents comprising ethylene and ethane. Being microporous materials, zeolites are generally used for performing catalytic and adsorbent purposes in chemical procedures. Use of ITQ-55 zeolite enables separation to be carried out with an unmatched degree of selectivity at ambient temperature. Outcomes of the analysis can also be applied to develop innovative materials that can be used as membranes or adsorbents in disparate gas separation applications related to the manufacture of chemical products.

Cryogenic distillation, the procedure which is currently used to separate ethylene on a commercial scale, is a process which consumes a lot of energy. If this new material is applied at a commercial scale, it could significantly reduce the amount of energy and emissions associated with ethylene production. This is another excellent example of collaboration between industry and academy, centered on promoting solutions to improve energetic efficiency and reduce the carbon emissions of industrial processes.

Vijay Swarup, Research and Development Vice President, The ExxonMobil Research and Engineering Company

Ethylene is an important constituent in the manufacture of plastic and chemical products often used in everyday life, thereby rendering the probe for substitutive technologies to isolate ethylene from ethane with reduced energy consumption a very active research field. Despite the fact that manufacturers of chemical products have assessed a sequence of substitutes to cryogenic distillation, comprising innovative adsorbents and separation techniques, a large number of these substitutive technologies are hampered by low efficiency and selectivity, and also the impracticability to regenerate adsorbents if they get degraded upon use because of the existence of contaminants.

The new ITQ-55 material has the potential to selectively isolate ethylene contained in ethane owing to its unique flexible and porous structure. The innovative material is formed of heart-shaped units interlinked by flexible and large channels, and allows only flat ethylene molecules to pass through but blocks the round ethane molecules. Hence, the innovative material functions like a flexible molecular sieve.

The ITQ-55 is a very interesting material, whose unique combination of pore sizes, topology, flexibility and chemical composition leads to a highly stable and chemically inert material which is able to adsorb ethylene and filter out ethane. We are thrilled with this discovery and hope to continue our fruitful collaboration with ExxonMobil.

Avelino Corma, Co-author of the study and CSIC Research Professor

More research has to be performed before commercializing the innovative material on a large scale. Additional investigations will be focused on including the material into a membrane for its industrial application, and also creating advanced materials for gas separation.

Our end goal of replacing cryogenic distillation is a long-term challenge that will require many more years of research and tests in and outside the laboratory. Our next steps will be focused towards a better understanding of the potential of this new zeolitic material.

Gary Casty, Head of ExxonMobil Research and Engineering Company’s catalysis section

The energy requirement of the chemical plants around the world is about 8% of global energy requirement, and this requirement is anticipated to scale up to 15% by the year 2040. As the population and standards of living on earth increase, the demand for construction materials, consumer goods, electronic devices, and other petrochemical by-products will also increase. ExxonMobil’s aim is to enhance industrial efficacy to satisfy the ever-increasing energy demand of the planet while reducing the effect on the environment.