Jun 1 2018

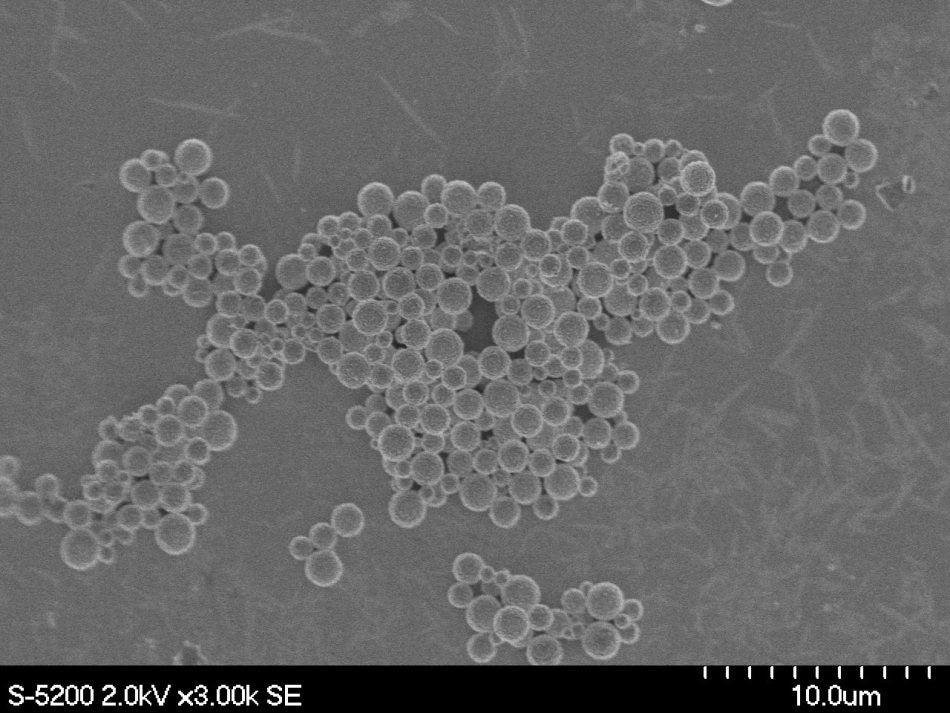

Scientist David Rosenberg inspects images of a white powder using a robust scanning electron microscope. At close range, the powder resembles coarse gravel, a pile of similar but uneven chunks. Then he studies a second image — the same material created by colleague Hongyou Fan instead of buying from a catalog — and he observes flawlessly smooth, uniform spheres.

Under high-power microscopy, a powder made with detergent-based technology at Sandia National Laboratories consists of perfect spheres. Without it, the material would look like coarse gravel. Consistency makes catalytic materials considerably more effective. (Photo courtesy of Hongyou Fan).

Under high-power microscopy, a powder made with detergent-based technology at Sandia National Laboratories consists of perfect spheres. Without it, the material would look like coarse gravel. Consistency makes catalytic materials considerably more effective. (Photo courtesy of Hongyou Fan).

I’ve never seen anything like this. At this scale, nobody can control the shape or the size that well. This technology does both.

David Rosenberg, Scientist

The uniform powder and others like it created at Sandia National Laboratories do not just look fine, they outclass commercial types used to trigger chemical reactions in solar cells and could be used to create clean-burning hydrogen fuel. If manufactured for industry, the new technology — topic of a recent paper in Nano Letters — could enhance performance while lowering costs of these and other catalysts used universally from environmental cleanup to cancer treatment.

Its key ingredient: detergent

Actually, it’s a commercial-grade version not dissimilar to household dish soap, minus the perfumes and dyes. Fan, the inventor of the detergent-based technology, and his team at the shared Advanced Materials Laboratory at the University of New Mexico use the active ingredient in cleaning solutions to capture raw materials just like grease, compressing them inside cages made up of detergent molecules. The cage serves as a molecular mold that orders the shape and size — or morphology — of the material that forms inside. Eliminate the detergent, and one is left with clean, uniform particles.

Normally, you would have very little control over the reaction that produces these materials. This leads to irregular morphology.

Hongyou Fan

That can be an issue for the engineers who employ those materials. Certain catalysts do not function unless they are set in specific ways at the molecular level, and certain light-absorbing particles used in solar cells soak up additional sunlight at specific sizes than others. When individual particles are uneven, only a fraction of the bulk material performs the way it’s designed to. The rest is dead weight, which also makes it hard to predict the catalyst’s performance.

Since Fan’s particles are uniform and firmly controlled, engineers could employ less material and achieve the same effect as conventional powders. In one research, Fan’s version of a photocatalyst, which could be utilized to clean wastewater, broke down five times more pollutant than its commercial equivalent. In his most recent paper, he showed similar enhancements in a material that catalytically creates hydrogen.

Consistency improves performance predictions

Rosenberg is expanding and applying the technology to his explosives study for national security, where volatile materials are undesirable. Together with a team that’s enhancing the inputs to computer models, “we saw an incredible, powerful application as it feeds into our modeling efforts,” he says.

Sandia creates computer simulations so that Rosenberg and his team do not have to physically construct and test parts each time. But assumptions that are placed into those models can sacrifice the output.

To reduce computing resources and time, a simulation may assume particles have simpler shapes or are more stable than they truly are. But, it will never flawlessly predict how the real material acts. Fan’s uniform powders line up the material with the model, offering Rosenberg the ability to regulate the particles’ structure so that many of the mathematical assumptions are eliminated.

“We could look at models that perfectly describe the physical characteristics of the powder, and that would give us an incredible tool both for validating existing models and for developing new ones.”

Change the detergent, change the shape

Fan also is enhancing materials for probable applications like energy conversion in solar cells, hydrogen production for clean fuel sources, and phototherapy for cancer treatment by developing distinguished particles in brand new shapes. One detergent may result in spheres, but Fan can swap it out for a detergent that creates rods, discs, or octahedrons. In the research that measured photocatalytic performance, he analyzed eight shapes against the commercial equivalent prior to selecting the most effective form.

But thus far, Fan has essentially discovered these shapes via trial and error. So he’s recruited the help of Younan Xia, a professor at the Georgia Institute of Technology and a pioneer in nanomaterial synthesis to speed up his work.

“We are measuring fundamental kinetics, how fast atoms or molecules are deposited on the surface of growing nanoparticles. The final structure of particles depends on that rate relative to the surface diffusion rate,” or the rate at which molecules drift away.

Xia and Fan are partnering together to create a recipe to imitate some shapes based on the detergent, pH value, temperature, and concentration. Similar to turning knobs, they could regulate these inputs to obtain a reliable output.

If you don’t have a quantitative knob, you might perform the experiment one hundred times before you get the right shape. With one, we hope we can get it right after the first or second try.

Younan Xia, Professor, Georgia Institute of Technology

Georgia Tech is a member of Sandia’s academic association. The association aims to solve the country’s important technical issues, develop the next-generation of researchers and engineers and speed-up the adoption of new technologies.

This study was financed by Sandia as a Laboratory Directed Research and Development project.

How Detergent Makes Catalysts More Potent

Sandia National Laboratories’ research to use detergent to make uniform powder catalysts. (Video courtesy of Sandia National Laboratories)