Jul 12 2018

Terahertz radiation can be used for a broad range of applications and is currently used for airport security checks and also for the analysis of materials in the laboratory. This radiation’s wavelength is in the millimeter range, indicating that it is considerably larger than the wavelength of visible light. It also needs specialized methods to manipulate the beams to get them into the correct shape.

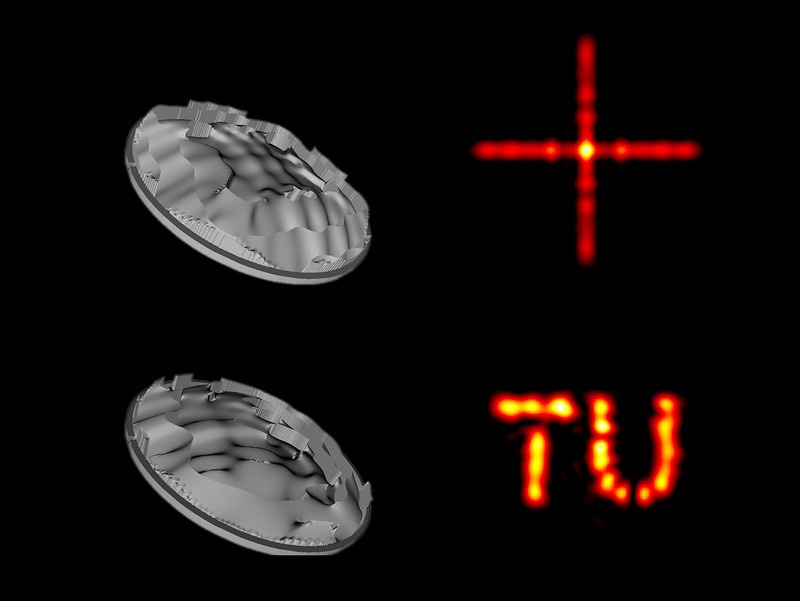

When the screens are inserted into the beam, the desired patterns emerge: a cross or the logo of TU Wien. (Image credit: TU Wien)

When the screens are inserted into the beam, the desired patterns emerge: a cross or the logo of TU Wien. (Image credit: TU Wien)

TU Wien researchers have been successfully shaping terahertz beams by using an accurately calculated plastic screen developed on the 3D printer, enabling the terahertz beams to be shaped as desired.

Like lenses—only better

Normal plastic is transparent for terahertz beams, in a similar way as glass is for visible light. However, terahertz waves slow down a little when they pass through plastic. This means that the crests and troughs of the beam become a little displaced—we call that phase shifting.

Professor Andrei Pimenov, the Institute of Solid State Physics, TU Wien

A beam can be shaped by using this phase shifting. Precisely the same thing takes place, in a rather simpler way, in the case of an optical lens made of glass: is the thickness of the lens is greater in the middle than on the edge, a light beam in the middle stays for longer in the glass compared to another beam that hits the edge of the lens at the same instant. Therefore, the light beams in the middle are more phase-delayed compared to those on the edge. This is precisely the reason for variation in the shape of the beam; it is possible to focus a wider light beam on a single point. Still, the probabilities are far more.

We didn’t just want to map a wide beam to a point. Our goal was to be able to bring any beam into any shape.

Jan Gosporadič, a PhD student in Andrei Pimenov’s team

The screen from the 3D printer

This can be accomplished through the insertion of an accurately adapted plastic screen into the beam. The diameter of the screen is only a few centimeters, with its thickness ranging from 0 to 4 mm. It is necessary to adjust the thickness of the screen gradually to ensure that different areas of the beam are deflected in a controlled manner, eventually leading to the desired image. A specialized calculation technique has been devised to obtain the desired screen design. This can then be used to produce the matching screen from an ordinary 3D printer.

“The process is amazingly simple,” stated Andrei Pimenov. “You don’t even need a 3D printer with an especially high resolution. If the precision of the structure is significantly better than the wavelength of the radiation used, then it’s enough — this is no problem for terahertz radiation with a 2mm wavelength.”

To underscore the potentials offered by the method, the researchers have produced different screens, which include one that changes a wide beam into the shape of the TU Wien logo. “This shows that there are hardly any geometric limits to the technology,” stated Andrei Pimenov. “Our method is relatively easy to apply, which leads us to believe that the technology will be rapidly introduced for use in many areas and that the terahertz technology that is currently emerging will make it a bit more precise and versatile.”