Aug 3 2018

Lubricity can be defined as the reduction in mechanical friction and wear by a lubricant. These are the leading reasons for energy loss and component failure in mechanical and electromechanical systems. For instance, one-third of the fuel-based energy in vehicles is expended in dealing with friction. Thus, superlubricity - the state of ultra-low friction and wear - holds great potential for the decrease of frictional wear in automatic and mechanical devices.

Image credit: Tel Aviv University

Image credit: Tel Aviv University

A new joint Tel Aviv University/Tsinghua University research finds that strong structural superlubricity can be attained between dissimilar, microscale-layered materials under ambient conditions and high external loads. The scientists discovered that microscale interfaces between graphite and hexagonal boron nitride reveal ultra-low friction and wear. This is a vital breakthrough for future technological applications in electronics, automotive, space, and medical industries.

The study is the product of a partnership between Prof. Oded Hod and Prof. Michael Urbakh of TAU's School of Chemistry; and Prof. Ming Ma and Prof. Quanshui Zheng of Tsinghua University's Department of Mechanical Engineering and their colleagues. It was conducted under the patronage of the joint TAU-Tsinghua collaborative XIN Center and was published in the July 30th issue of Nature Materials.

Enormous implications for computer and other devices

The new interface is six orders of magnitude larger in surface area than previous nanoscale measurements and displays strong superlubricity under ambient conditions and in all interfacial orientations.

"Superlubricity is a highly intriguing physical phenomenon, a state of practically zero or ultra-low friction between two contacting surfaces," says Prof. Hod. "The practical implications of achieving robust superlubricity in macroscopic dimensions are enormous. The expected energy savings and wear prevention are huge."

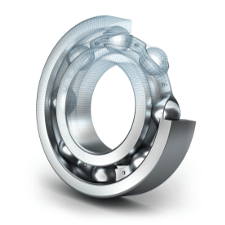

"This discovery may lead to a new generation of computer hard discs with a higher density of stored information and enhanced speed of information transfer, for example," adds Prof. Urbakh. "This can be also used in a new generation of ball bearing to reduce rotational friction and support radial and axial loads. Their energy losses and wear will be significantly lower than in existing devices."

The research’s experimental portion was performed using atomic force microscopes at Tsinghua and the totally atomistic computer simulations were done at TAU. The scientists also described the degree of crystallinity of the graphitic surfaces by performing spectroscopy measurements.

Close collaboration

The research developed from a previous prediction by theoretical and computational groups at TAU that strong structural superlubricity could be attained by creating interfaces between the materials graphene and hexagonal boron nitride. "These two materials are currently in the news following the 2010 Nobel Prize in Physics, which was awarded for groundbreaking experiments with the two-dimensional material graphene. Superlubricity is one of their most promising practical applications," says Prof. Hod.

"Our study is a tight collaboration between TAU theoretical and computational groups and Tsinghua's experimental group," says Prof. Urbakh. "There is a synergic cooperation between the groups. Theory and computation feed laboratory experiments that, in turn, provide important realizations and valuable results that can be rationalized via the computational studies to refine the theory."

The study groups are continuing to work together in this field exploring the fundamentals of superlubricity, its widespread applications, and its effect in ever larger interfaces.