According to the Centers for Disease Control and Prevention (CDC), almost one-quarter of the U.S. population suffers from some form of arthritis. Everyday tasks—such as opening drawers, turning door handles—can be challenging, so people resort to adaptive aids. A number of these are small pieces of plastic.

Hence, Pearce made his students to make attempts in this line. Currently, Pearce is a co-author and corresponding researcher on an innovative study that investigates how 20 of the 3D-printed adaptive aids created by his students achieve huge cost savings and satisfy, or improve, standards for prevalent products. The research was published this week in Geriatrics (DOI: 10.3390/geriatrics3040089) and is co-authored by Nicole Gallup, student research assistant, and Jennifer Bow, an orthopedic surgeon who is also a visiting scholar at Michigan Tech.

Here are photo examples of the devices students printed.

Adaptive aids help modify everyday tasks.

Many people could use help with dog leash clasps; this device slips under the release and uses a whole-hand motion, instead of a smaller and finger-focused pinching motion.

3-D printing designs can include other materials — like the screws in this knife guide.

Especially for older patients with arthritis, being able to maintain independent living and take care of their own health and medicine with devices like pill splitters is important.

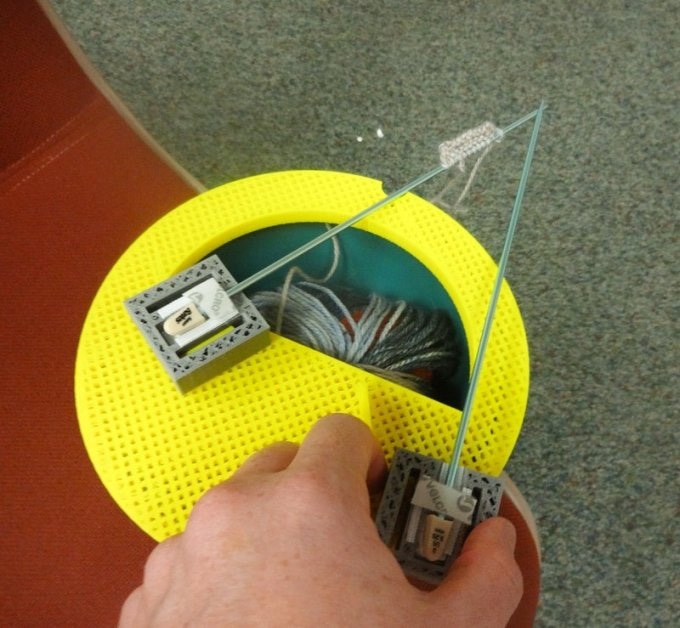

Adaptive aids can help people continue doing hobbies like knitting.

More Pain, No Gain

Adults suffering from arthritis and other rheumatic conditions earn less compared to average Americans; however, they spend more on medical expenses: on average around 12% of the average family’s income. Moreover, the adaptive aids they might have to buy to assist them in pulling on socks, pulling zippers, holding toothbrushes, cutting food, knitting, and many other daily tasks are expensive.

The cost of adaptive aids ranges from $5.99 for an inexpensive pop can opener, $23.75 for a pill splitter, to $49.99 for a phone holder. Using 3D printing can reduce those costs to 45 cents for pop tabs, $1.27 for splitting pills, and 79 cents plus a rubber band for holding a phone.

Apart from being less expensive, the 3D-printed versions are also customizable. Dr Bow suggested the students to have a glance at designing adaptive aids since the customization offered by 3D printers could help her arthritis patients and others across the globe. Thereafter, the team Makers Making Change approached Pearce as they wanted to improve certain existing designs that can be expanded, shrunk, and adjusted to match different hand sizes, color preference, grip strengths, and task modification.

This is the difference between needing to go to someone to get your nails cut and being able to do your own, which, yes, there’s cost savings, but it’s also personal pride and being able to take care of yourself. And if your only problem is that the standard nail clipper is too tiny, we can fix that.

Joshua Pearce, Richard Witte Endowed Professor of Materials Science and Engineering, Michigan Tech.

The cost of individual items may not be very high. Yet, after a diagnosis, it might be necessary for certain patients to install or overhaul many adaptive aids, such as putting light switch flippers throughout the house, which adds up quickly. 3D printing can cut down on that cost, and Pearce and his colleagues only used printers with a cost of $500 or less; however, the upfront cost of a printer may inhibit the spirit of some people. Moreover, it is not necessary for some people to pay the full price for adaptive aids if Medicare or their insurance policy helps cover the purchases. According to Pearce, neither considerably affects the numbers.

“We printed and analyzed 20 different products and each one has a great return on investment, even for people who can use insurance to purchase adaptive aids with a co-pay, and a printer pays for itself easily,” stated Pearce, explaining that the true challenge is not economic. “It’s a slam dunk—but the question becomes how do people get these aids?”

Access to 3D Printing

A 3D printer on the kitchen table can save a lot for people. Although not all are prepared for the distributed manufacturing wave in their home, many ways exist to make 3D-printed goods available to people with arthritis, specifically older patients.

“We’re not saying an 85-year-old with no personal computer experience is developing a CAD from scratch and prototyping a design 12 times,” stated Pearce, explaining that the open source designs are available for free online at Appropedia and MyMiniFactory.

According to Pearce, doctor’s offices, nursing homes, and physical therapy clinics are the ideal hubs for 3D-printed adaptive aids. Libraries and local makerspaces also provide access to designs, printers, and knowledgeable people in exchange for fees that cover plastic and printing costs; certain businesses even make a living offering 3D prints.

Printed for Class

Bearing that dream in mind, Pearce stated that his students began with base functionality. Their assignment, completed in a week, was printed on Rep-Rap printers developed by the students themselves in the first two weeks of class. They carried out all their adaptive aid prints with PLA plastic, concentrated on handheld items, and several students designed features having a friend, loved one, or an acquaintance in mind. Although all the aids, there is still room for improvement.

All the designs could be made much prettier and better—and that’s the beauty of open source. Because I hope in a couple years that we have a whole array of each one of these ideas that’s built out much further, applied all over the world and customized for individual people. This is a new field of 3D printing design that’s just getting started. Lots of people can make real, honest-to-goodness, concrete contributions.

Joshua Pearce, Richard Witte Endowed Professor of Materials Science and Engineering, Michigan Tech.