Mar 18 2019

A research team comprising of scientists at the U.S. Department of Energy’s (DOE) Brookhaven National Laboratory and SLAC National Accelerator Laboratory has discovered the causes of degradation in a cathode material for lithium-ion batteries, and also potential remedies.

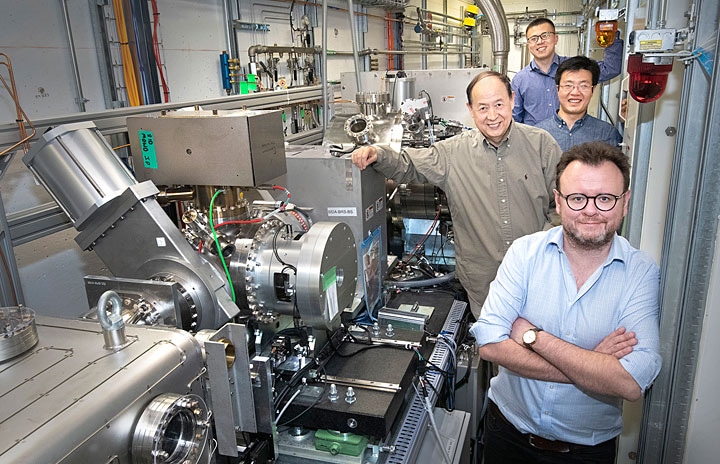

Members of the Brookhaven team are shown at NSLS-II’s ISS beamline, where part of the research was conducted. Pictured from front to back are Eli Stavitski, Xiao-Qing Yang, Xuelong Wang, and Enyuan Hu. (Image credit: Brookhaven National Laboratory)

Members of the Brookhaven team are shown at NSLS-II’s ISS beamline, where part of the research was conducted. Pictured from front to back are Eli Stavitski, Xiao-Qing Yang, Xuelong Wang, and Enyuan Hu. (Image credit: Brookhaven National Laboratory)

The study outcomes, reported on March 7th, 2019 in Advanced Functional Materials, could make the development of more affordable and superior performing batteries for electric vehicles possible.

Searching for High-Performance Cathode Materials

Electric vehicles require lightweight yet powerful batteries to offer the same reliability as gas vehicles. Presently, the most common type of battery found in electric vehicles is lithium-ion batteries; however, their high cost and restricted lifetimes are drawbacks to the extensive deployment of electric vehicles. To solve these problems, researchers at many of DOE’s national labs are finding ways to enhance the conventional lithium-ion battery.

Batteries are made up of a cathode, an anode, and an electrolyte, but several researchers consider the cathode to be the most serious issue. Scientists at Brookhaven are part of a DOE-sponsored consortium known as Battery500, a team that is working to improve the energy density of the batteries that power present electric vehicles by three times. Optimization of a class of cathode materials known as nickel-rich layered materials is one of their objectives.

Layered materials are very attractive because they are relatively easy to synthesize, but also because they have high capacity and energy density.

Enyuan Hu, Study Author and Chemist, Brookhaven National Laboratory

Lithium cobalt oxide, a layered material, has been used as the cathode for lithium-ion batteries for several years. Although it finds successful application in small energy storage systems, for example, portable electronics, cobalt’s toxicity and cost are hurdles for the material’s use in bigger systems. Presently, investigators are examining how to replace cobalt with safer and more reasonably priced elements without affecting the performance of the material.

“We chose a nickel-rich layered material because nickel is less expensive and toxic than cobalt,” Hu said. “However, the problem is that nickel-rich layered materials start to degrade after multiple charge-discharge cycles in a battery. Our goal is to pinpoint the cause of this degradation and provide possible solutions.”

Determining the Cause of Capacity Fading

There are a number of ways by which cathode materials degrade. The main issue for nickel-rich materials is capacity fading, which is a reduction in the battery’s charge-discharge capacity after use. To completely understand this process in their nickel-rich layered materials, the researchers had to use multiple research methods to evaluate the material from various viewpoints.

“This is a very complex material. Its properties can change at different length scales during cycling,” Hu said. “We needed to understand how the material’s structure changed during the charge-discharge process both physically—on the atomic scale up—and chemically, which involved multiple elements: nickel, cobalt, manganese, oxygen, and lithium.”

In order to perform this, Hu and his team characterized the material at multiple research facilities, including two synchrotron light sources—the National Synchrotron Light Source II (NSLS-II) at Brookhaven and the Stanford Synchrotron Radiation Lightsource (SSRL) at SLAC. Both are user facilities of the DOE Office of Science.

At every length scale in this material, from angstroms to nanometers and to micrometers, something is happening during the battery’s charge-discharge process. We used a technique called x-ray absorption spectroscopy (XAS) here at ISS to reveal an atomic picture of the environment around the active metal ions in the material.

Eli Stavitski, Study Co-Author and Beamline Scientist, NSLS-II’s Inner Shell Spectroscopy (ISS) Beamline

From the results of the XAS experiments at NSLS-II, the scientists concluded that the material had a sturdy structure that did not discharge oxygen from the bulk, challenging earlier assumptions. Instead, the scientists found that the strain and local disorder was mainly related to nickel.

To study further, the research group carried out transmission X-ray microscopy (TXM) experiments at SSRL, mapping out all the chemical distributions in the material. This method generates a very large set of data, hence the researchers at SSRL applied machine learning to sort through the data.

These experiments produced a huge amount of data, which is where our computing contribution came in. It wouldn’t have been practical for humans to analyze all of this data, so we developed a machine learning approach that searched through the data and made judgments on which locations were problematic. This told us where to look and guided our analysis.

Yijin Liu, Study Co-Author and Staff Scientist, SLAC

Hu said, “The major conclusion we drew from this experiment was that there were considerable inhomogeneities in the oxidation states of the nickel atoms throughout the particle. Some nickel within the particle maintained an oxidized state, and likely deactivated, while the nickel on the surface was irreversibly reduced, decreasing its efficiency.”

Additional experiments demonstrated small cracks created within the material’s structure.

During a battery’s charge-discharge process, the cathode material expands and shrinks, creating stress. If that stress can be released quickly then it does not cause a problem but, if it cannot be efficiently released, then cracks can occur.

Enyuan Hu, Study Author and Chemist, Brookhaven National Laboratory

The researchers thought that they could probably alleviate this issue by producing a new material with a hollowed structure. They tested and proved that theory both experimentally and through calculations. Going further, the team intends to continue developing and characterizing new materials to improve their efficiency.

“We work in a development cycle,” Stavitski said. “You develop the material, then you characterize it to gain insight on its performance. Then you go back to a synthetic chemist to develop an advanced material structure, and then you characterize that again. It’s a pathway to continuous improvement.”

Moreover, as NSLS-II continues to develop its potentials, the researchers intend to execute more sophisticated TXM experiments on these types of materials, leveraging NSLS-II’s ultrabright light.

This research was supported by the National Science Foundation and DOE’s Office of Energy Efficiency and Renewable Energy. DOE’s Office of Science supported the operations at NSLS-II and SSRL.