May 22 2019

A majority of the lithium batteries available today contain a liquid packed between a pair of solid materials. However, the traditional example is likely to get some competition, as researchers have started to explore batteries containing all solid materials.

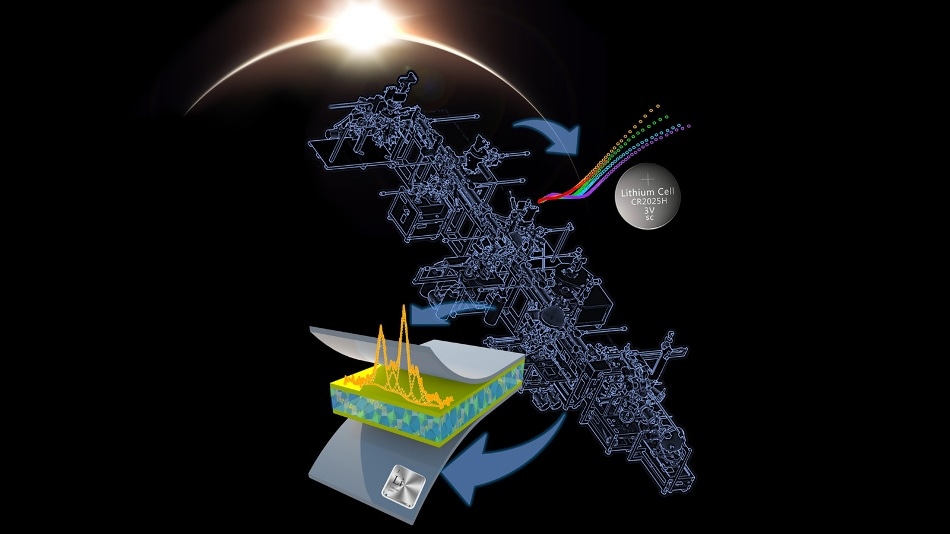

This multi-module ultrahigh vacuum system (in blue) allowed Argonne researchers to create and probe the interface of a solid electrolyte with a lithium metal anode without air exposure. This experiment correlated interfacial chemistry with the electrochemical response of the system. (Image credit: Argonne National Laboratory/Sanja Tepavcevic)

This multi-module ultrahigh vacuum system (in blue) allowed Argonne researchers to create and probe the interface of a solid electrolyte with a lithium metal anode without air exposure. This experiment correlated interfacial chemistry with the electrochemical response of the system. (Image credit: Argonne National Laboratory/Sanja Tepavcevic)

When compared to batteries using a liquid electrolyte, solid-state lithium batteries provide a number of benefits. Most significantly, solid-state lithium batteries make it viable to use lithium metal anodes that are capable of storing more amounts of energy in a smaller volume. Furthermore, most of the chemical behavior of solid-state batteries is yet to be examined, but now researchers are focusing on the areas between the battery’s solid electrolyte and its anode.

In a recent study performed by the U.S. Department of Energy’s (DOE) Argonne National Laboratory, scientists have discovered a novel boundary layer that arises between a lithium lanthanum zirconium oxide (LLZO) electrolyte and a lithium metal anode.

This new boundary layer looks like the solid-electrolyte interphase region existing in liquid-electrolyte batteries and that usually have a considerable impact on the performance of batteries. Similar to the solid-electrolyte interphase, the “oxygen-deficient interphase” existing between the pair of solid battery components establishes the battery’s stability as a whole.

In order to enhance the potential of the solid electrolyte to convey the lithium ions to and fro between the cathode and anode of the battery, and to stabilize the electrolyte’s structure, other metals were integrated within the LLZO electrolyte in a process referred to as doping.

The researchers from Argonne National Laboratory examined the LLZO doped with three metals, such as aluminum, niobium, and tantalum. All the three metals were observed to have a different impact on the battery material’s performance. When lithium metal was sputtered on the niobium-doped electrolyte, the scientists observed that the increased reactivity of the electrolyte had an impact on the oxygen-deficient interphase. This consecutively increased the material’s resistivity, leading to the ultimate failure of the battery as the lithium entered into the bulk of the electrolyte.

However, a different picture emerged when the team utilized a material doped with tantalum. The tantalum did not favorably moved to the region close to the oxygen-deficient interphase, and consequently acted to steady the electrolyte without increasing the resistivity. The aluminum entirely took up a different space within the lattice.

To produce the oxygen-deficient interphase, the lithium anode has to be brought into a complete, direct contact with the electrolyte. However, this process is generally complicated by the LLZO and also by the exposure of lithium metal to the ambient environment.

You can think of it as like trying to have two surfaces of Velcro® latch on to each other perfectly. If you have a film or dirt that gets in the way, you’re not going to be able to make the connection.

Peter Zapol, Study Co-Author, Physicist, Argonne National Laboratory

Calculations demonstrated that niobium and tantalum act in a different way at clean lithium metal/LLZO interfaces, supporting the concept of oxygen-deficient interphase.

To ensure the highest contact between the electrolyte and the anode, the team cleaned and polished the lithium metal/LLZO interfaces under ultra-high vacuum.

Approaches targeting this interface have run into difficulties getting the degree of contact necessary to reveal the full dynamics possibly present at the interface. With the tools we have at our disposal, however, we are able to see the full range of interfacial properties, as well as their relationship to the different dopants.

Sanja Tepavcevic, Study Co-Author and Materials Scientist, Argonne National Laboratory

We have only scratched the surface in understanding solid-state electrolyte interfaces. Our integrated experimental and computational approach gives us the opportunity to look at intrinsic properties of these materials.

Nenad Markovic, Distinguished Fellow and Materials Scientist, Argonne National Laboratory

A paper based on the study titled, “Dopant-dependent stability of garnet solid electrolyte interfaces with lithium metal,” was published in the March 27th, 2019 issue of Advanced Energy Materials. Apart from Tepavcevic and Zapol, other Argonne authors included Yisi Zhu, Brian Ingram, Justin Connell, Larry Curtiss, Dillon Fong, and John Freeland. Nathan Taylor, Jeff Sakamoto, and Regina Garcia-Mendez from the University of Michigan also collaborated in the study.

The study was funded by DOE’s Office of Energy Efficiency and Renewable Energy and Office of Science, the latter partly through the Joint Center for Energy Storage Research, a DOE Energy Innovation Hub.