Sensor solutions provider HENSOLDT together with the leading Additively Manufactured Electronics (AME)/Printed Electronics (PE) provider, Nano Dimension, has achieved a major breakthrough on its way to utilizing 3D printing in the development process of high-performance electronics components. Utilizing a newly developed dielectric polymer ink and conductive ink from Nano Dimension, HENSOLDT succeeded in assembling the world-wide first 10-layer printed circuit board (PCB) which carries high-performance electronic structures soldered to both outer sides. Until now, 3D printed boards could not bear the soldering process necessary for two sided population of components.

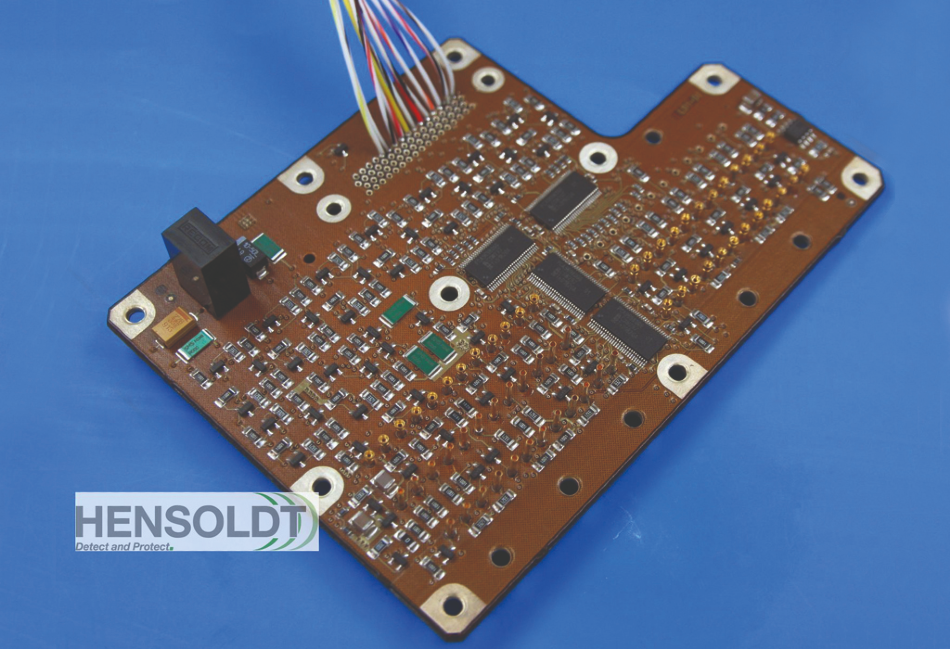

HENSOLDT’s 10-layer printed circuit board (PCB) with populated outer sides. Image Credit: HENSOLDT

HENSOLDT’s 10-layer printed circuit board (PCB) with populated outer sides. Image Credit: HENSOLDT

“Military sensor solutions require performance and reliability levels far above those of commercial components.” says HENSOLDT CEO, Thomas Müller. “To have high-density components quickly available with reduced effort by means of 3D printing gives us a competitive edge in the development process of such high-end electronic systems.”

“Nano Dimension’s relationship with HENSOLDT is the type of partnership with customers we are striving for,” commented Yoav Stern, Nano Dimension President & CEO. “Working together and learning from HENSOLDT led us to reach a first-of-its-kind in-depth knowledge of polymer materials applications. Additionally, it guided us in the development of Hi-PEDs (High Performance Electronic Device) that create competitive edges by enabling unique implementations with shortest time to market.”

AMEs are useful to verify a new design and functionality of specialized electronic components before production. AME is a highly agile and individual engineering methodology to prototype a new electronic circuitry. This leads to significant reduction of time and cost in the development process. Furthermore AME allows for a verified and approved design before production starts, leading to higher quality of the final product.

HENSOLDT started working with Nano Dimension’s DragonFly 3D printing system in 2016, in order to examine the possibilities of 3D printing electronics. Last year, HENSOLDT successfully implemented the DragonFly Lights-Out Digital Manufacturing (LDM) printing technology, the industry’s only additive manufacturing platform for round-the-clock 3D printing of electronic circuitry.