Reviewed by Alex SmithSep 22 2021

Carbon fiber reinforced polymer composite structures have a highly crucial role in energy generation, aerospace, transportation and infrastructure.

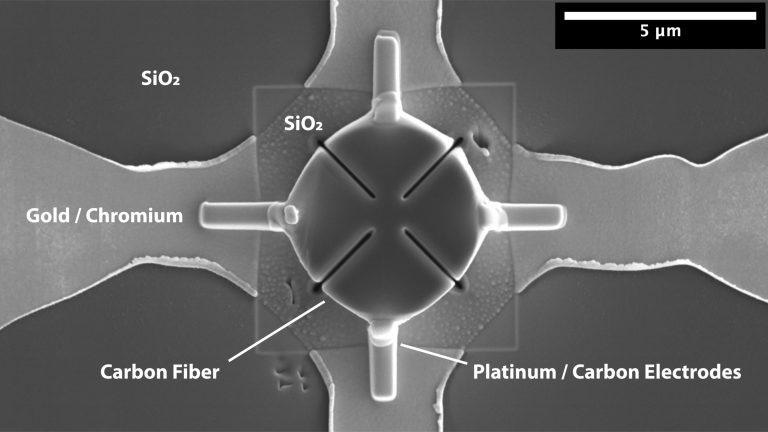

The slice of carbon fiber in the micro-electric circuit is electrically connected to the gold/chromium electrodes with platinum/carbon electrodes. Image Credit: Satoshi Matsuo and Nancy R. Sottos.

The slice of carbon fiber in the micro-electric circuit is electrically connected to the gold/chromium electrodes with platinum/carbon electrodes. Image Credit: Satoshi Matsuo and Nancy R. Sottos.

However, a composite’s electrical behavior is difficult to quantify or predict due to the electrical conductivity of constituent carbon fibers and the complex hierarchical microstructure of the composite.

Scientists from the University of Illinois at Urbana-Champaign have come up with the first-ever direct measurement of the transverse electrical resistivity of a single carbon fiber. They integrated an accurate sample preparation with a method called the van der Pauw technique to achieve this difficult measurement.

The study has been reported in the Journal of Applied Physics, by AIP Publishing.

Our experiments confirm that the electrical properties measured transverse to a carbon fiber are not the same as the properties measured along the length of the fiber.

Nancy Sottos, Study Co-Author, University of Illinois at Urbana-Champaign

While manufacturing carbon fibers, the strong carbon-carbon covalent bonds tend to become aligned in planes parallel to the fiber axis in the longitudinal direction.

The occurrence of only weak van der Waals bonds between the planes in the transverse direction causes directionally dependent properties.

Using the van der Pauw method, the team precisely measured the resistivity of a carbon fiber in the transverse direction.

The resistance measurements were executed on a slice of carbon fiber cut using a focused ion beam and connected to electrodes for electrical resistance measurements.

Our results reveal that an IM7 carbon fiber is more electrically conductive in the direction parallel to the length.

Satoshi Matsuo, Study Co-Author, University of Illinois at Urbana-Champaign

The van der Pauw method was predominantly used previously to quantify the resistivity of thin films or disks. The team cut and manipulated a carbon fiber slice with a focused ion beam and a needle, a tool that is more often used to make transmission electron microscopy specimens.

Currently, the team is working on measurements of electrical contact resistance between two carbon fibers.

The electrical contact resistance is based on the electrical resistivity and the contact area, which also differs based on the angle at which the two fibers cross each other.

As a next step, the researchers plan to investigate the transverse electrical resistivity measurements on various types of carbon fibers under different measurement conditions such as the ambient temperature.

This procedure may also be applied to other homogenous conductive fibrous materials with a diameter on the order of microns such as conductive polymer fiber or metallic fiber.

Nancy Sottos, Study Co-Author, University of Illinois at Urbana-Champaign

Journal Reference:

Matsuo, S., et al. (2021) Single carbon fiber transverse electrical resistivity measurement via the van der Pauw method. Journal of Applied Physics. doi.org/10.1063/5.0060126.