High-entropy alloys are a newcomer in the alloy material world and surpass the conventional alloy design concept, thanks to more than five of their constituent elements. They also have a simple solid solution structure because of their high configuration entropy.

High entropy alloy-based high-temperature solar selective absorbing coating enabled by a combination of optical simulation and magnetron sputtering. Image Credit: LICP.

High entropy alloy-based high-temperature solar selective absorbing coating enabled by a combination of optical simulation and magnetron sputtering. Image Credit: LICP.

High-entropy alloys exhibit superior mechanical properties, have the ability to endure heat and are resistant to corrosion, wear and irradiation, thus having great potential for advancement in the renewable energy industry.

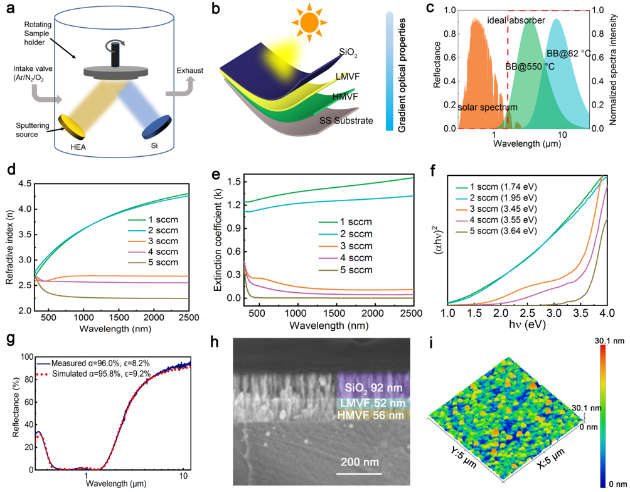

A team of researchers headed by Associate Professor Xianghu Gao and Professor Gang Liu at the Lanzhou Institute of Chemical Physics of the Chinese Academy of Sciences (CAS) recently synthesized a range of high-entropy alloy-based high-temperature solar selective absorbing coatings by using the methods of component modulation, conformational entropy optimization and structural design with high-entropy nitrides.

The team has engineered a color solar selective absorbing coating with an infrared reflective layer of high-entropy alloy nitride, aluminum, silicon dioxide and high-entropy alloy nitrogen oxide. This facilitates a thermal emittance of less than 10% and high solar absorption of 93.5%.

Then, they identified that a single layer of high-entropy alloy nitride ceramics also exhibited optimal intrinsic absorption properties, and thus, they synthesized a coating with a simple structure.

High-entropy alloy nitride was used as the absorption layer and Si3N4 or SiO2 was used as the antireflective layer. Thus, a coating with an absorption of 92.8% and emissivity of less than 7% was achieved, exhibiting ideal thermal stability in vacuum at 650 °C for 300 hours.

The researchers further improved the absorption capacity of the absorber by choosing low-nitrogen content high-entropy alloy films as the main absorption layer, stainless steel as the substrate, high-nitrogen content high-entropy alloy films as the extinction interference layer and Al2O3, SiO2 or Si3N4 as the antireflection layer. This led to a structure with gradually reducing optical constants from the substrate to the surface.

The researchers used a combination of optical simulation and magnetron sputtering techniques to enhance the preparation efficiency, contributing to a superior solar absorption of 96% and a low thermal emission of less than 10%.

Then, the researchers analyzed the light absorption mechanism with Finite-Difference Time-Domain simulation. The high-entropy alloy nitride-based absorber still retained optimal optical properties even after annealing at 600 °C in a vacuum for 168 hours, denoting its excellent thermal stability.

The absorber’s photothermal conversion efficiency was estimated at various concentration ratios and operating temperatures, and the efficiency could reach 90.1% at an operating temperature of 550 °C and 100 suns.

When compared to the most advanced absorber reported recently, the high-entropy alloy-based absorber showed both superior photothermal conversion efficiency and thermal stability.

The absorbers were deposited on various substrate materials, maintaining superior optical properties and realizing large-scale preparation on aluminum foil. A study of the absorption spectra at various incident angles showed that the absorption coating exhibited good absorption in the range of the incident light angle of 0°-60°.

When subjected to radiation from simulated sunlight, the coating surface temperature surpassed 100 ℃, showing that the material could be promising for the field of interfacial water evaporation.

High-temperature solar selective absorbing coatings with superior optical properties and high temperature resistance were prepared as part of this study, expanding the functional applications of high-entropy alloys in the area of new energy materials.

This study was funded by the Youth Innovation Promotion Association of CAS, the Regional Key Projects of the Science and Technology Service Network Program of CAS, and the Major Science and Technology Projects of Gansu Province.

Journal Reference:

Guo, H.-X., et al. (2021) A novel multilayer high temperature colored solar absorber coating based on high-entropy alloy MoNbHfZrTi: Optimized preparation and chromaticity investigation. Solar Energy Materials and Solar Cells. doi.org/10.1016/j.solmat.2020.110444.