A concept that dates back to the 1980s, ‘frugal manufacturing’ considers that in order to maximize efficiency and profitability, manufacturers should look to use smaller, more agile, and highly resource-efficient factories and production lines rather than continuing to look to larger, faster, and more sophisticated production line technologies.

The use of fewer raw materials and minimal process steps are both key factors in a product’s ‘green’ credentials and its place in the wider culture of sustainable development.

![Improvement in factor of frugality of a shaft through various material saving schemes, including manufacturing, considered in a natural sequence [14].](https://www.azom.com/images/news/ImageForNews_57613_16389643068795940.jpg)

Improvement in factor of frugality of a shaft through various material saving schemes, including manufacturing, considered in a natural sequence. Image Credit: Rao Balkrishna C., Open Sci

This concept of frugal resource consumption in manufacturing has led to the development and widespread adoption of an array of sophisticated frugal products which offer functionality and performance on par with similar items, despite being low cost and requiring minimal resources to produce.

This approach has been leveraged in the design and manufacture of products ranging from cars to medical devices via lighting solutions.

The concept of frugal manufacturing has also been the focus of policy developments, with organizations such as the Environmental Protection Agency (EPA) and the National Academy of Engineering recognizing the vital need to meet the demand for these tools and products while optimizing the use of often scarce natural resources.

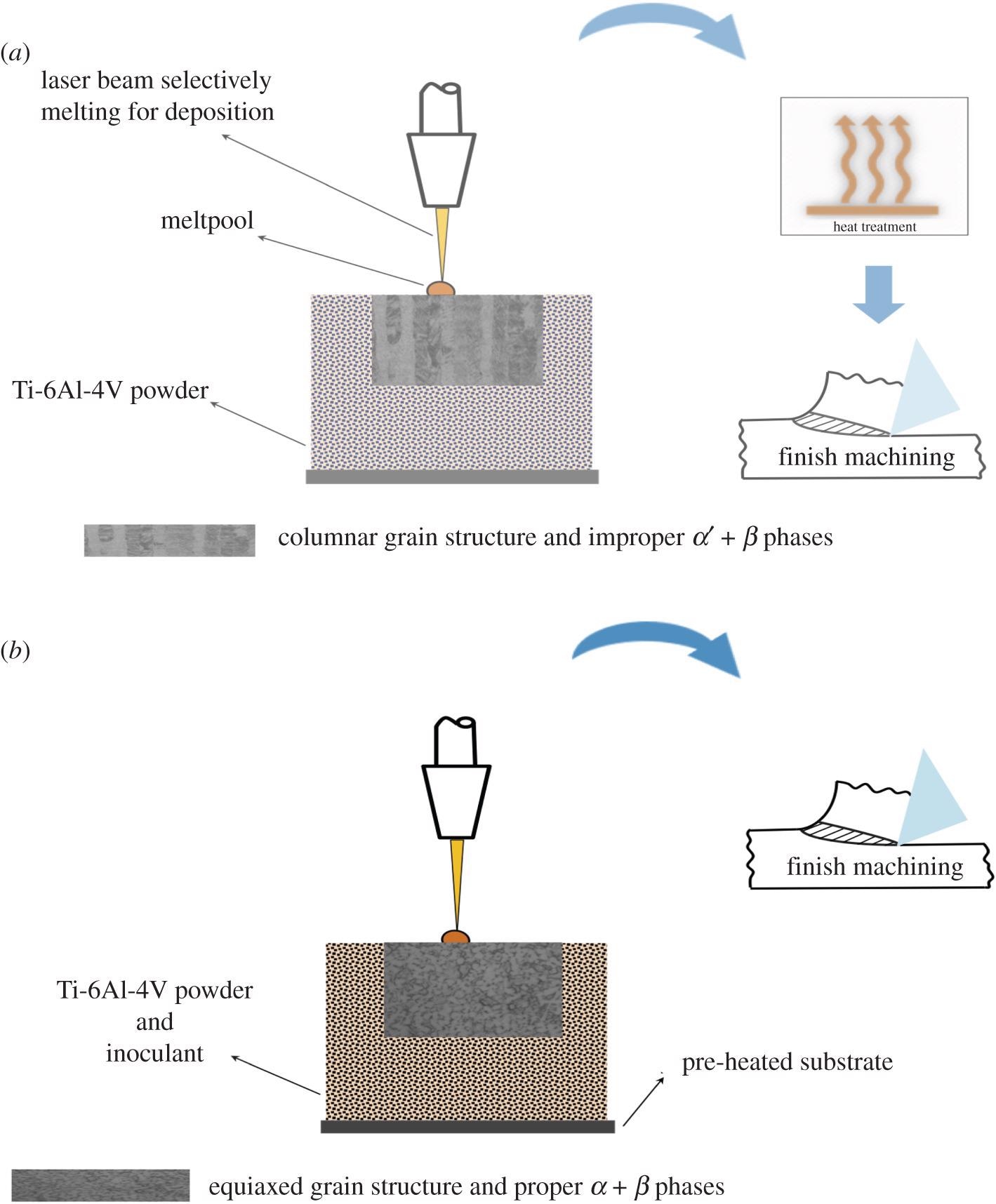

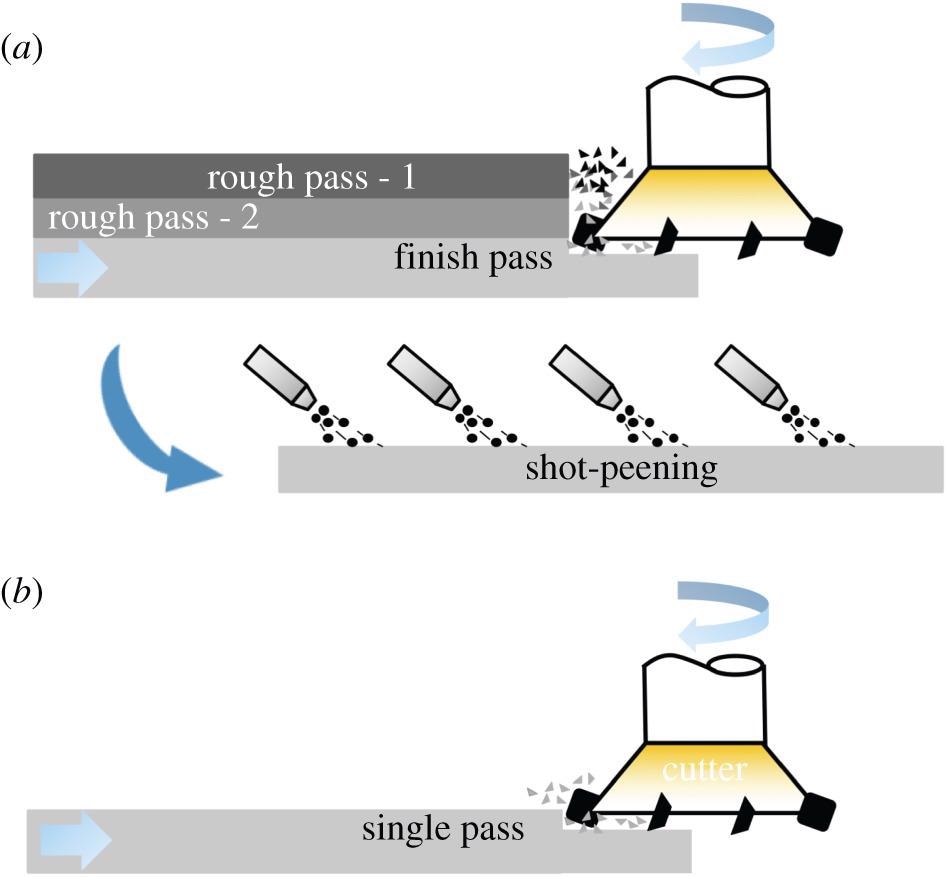

Two other concepts are important when conceptualizing frugal manufacturing: near net shapes (NNS’s) represent products that require some form of finishing to reach their ultimate usable form. This ultimate and final form – essentially the final product ready for application – is referred to as a net finished shape (NFS).

Frugal manufacturing can be best defined as fabrication which produces zero waste while using the minimal required process steps to produce a net finished shape.

In order to be useful in its application, a net finished shape must possess all the attributes, robustness, and functionality required for its destined use – this point is important because frugal manufacturing should have no negative impact on established product quality.

Frugal manufacturing processes require that precisely the correct amount of raw materials be employed in a product’s manufacture, meaning that designs must often be revised and optimized to avoid waste and reduce process steps. An effective frugal design would, for example, reduce raw material costs and reduce power consumption during manufacturing.

Additive manufacturing as a frugal process. (a) Selective laser melting as an AM process, (b) selective laser melting as a frugal process. Image Credit: Rao Balkrishna C., Open Sci

These reduced requirements would likely have a notable impact on the greenhouse gas emissions from the process in question due to its reduced power consumption, and the use of minimal raw materials would have a cascading impact on the processes of producing, mining, farming, or otherwise acquiring these; potentially improving sustainability at multiple points throughout the value and supply chains.

Working towards the production of near-net shapes was previously considered the norm in terms of process optimization, but a frugal manufacturing approach – which aims to develop net finished shapes as part of zero-waste processes – can be understood to be a more stringent, advanced, and arguably more relevant evolution of this approach.

It is also important to note that these concepts have evolved in line with current manufacturing methods. For example, the near-net shapes approach aimed to reduce waste, ensure functionality and minimize product defects, but this approach had primarily been considered in line with traditional bulk and sheet operations.

Research into and conceptualizations of frugal manufacturing have been applied to virtually the entire range of manufacturing approaches, as well as more contemporary subtractive and additive manufacturing techniques.

The paper’s author implies that any efforts towards a frugal manufacturing approach will support sustainability efforts, not least when working with raw materials that may be complex to produce or challenging to source.

Looking to the future, the author also highlights that it would be prudent to interlink the concepts and approaches to frugal manufacturing with Industry 4.0, leveraging the power of smart processes and connected systems to optimize and ‘frugalize’ a diverse array of manufacturing processes.

Developments such as the adoption of digital twins, artificial intelligence, and machine learning offer the potential to further advance, automate and optimize frugal manufacturing approaches.

In order to achieve truly sustainable development and to rise to the pressing challenge of the climate emergency, it is important that resource consumption be minimized across all sectors and industries.

High-speed machining as a frugal process. (a) Conventional machining followed by shot-peening, (b) high-speed machining for frugal cutting. Image Credit: Rao Balkrishna C., Open Sci

Recent advances in automation, process control, and process optimization offer new means of better optimizing and leveraging frugal manufacturing processes.

The implementation and more widespread adoption of frugal manufacturing principles and approaches are one means of ensuring that processes generate zero waste and demonstrate minimal power consumption while continuing to offer products that meet all required specifications and tolerances.

References

Rao Balkrishna C. 2021. Frugal manufacturing in smart factories for widespread sustainable development. R. Soc. open sci.8210375210375 https://royalsocietypublishing.org/doi/10.1098/rsos.210375

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.