Researchers from the Jawaharlal Nehru Centre for Advanced Scientific Research in India have reported the use of twisted multilayer graphene (tMLG) to develop an ultrafast supercapacitor. The findings of their study are currently in the pre-proof stage in the journal Materials Research Bulletin.

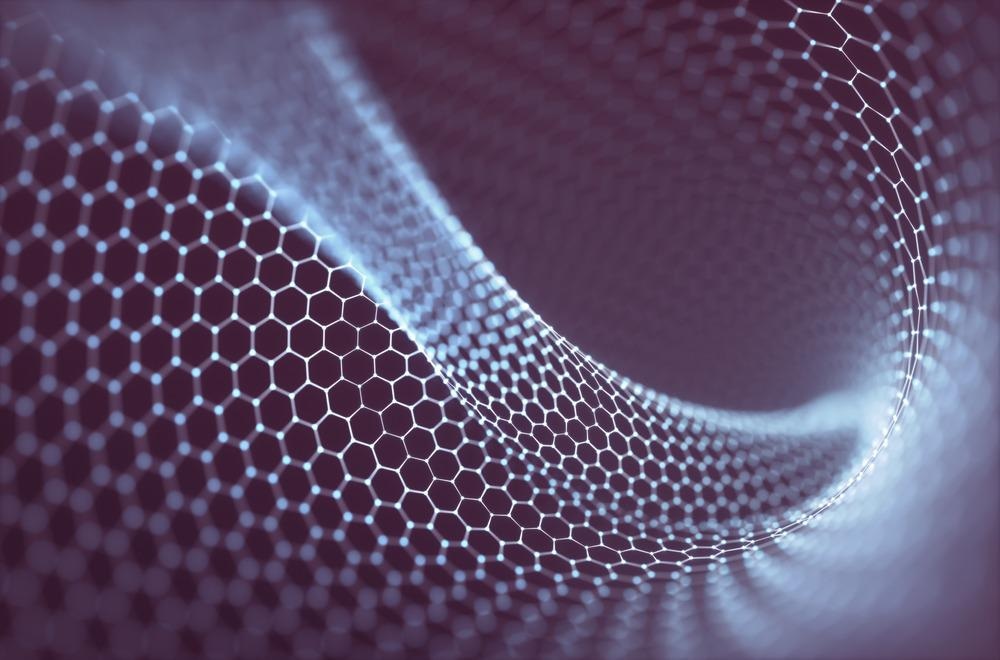

Study: Ultrafast planar microsupercapacitor based on defect-free twisted multilayer graphene. Image Credit: ktsdesign/Shutterstock.com

The Demand for Ever-Smaller Electronic Components

IoT is a key technology in Industry 4.0. Increasing demand for devices that communicate via technologies such as Wi-Fi and Bluetooth has driven the increased integration of microelectronics. Elements such as batteries occupy a large amount of space in devices, and because of this, replacing them with smaller, more compact components is of key concern to researchers working in the field of electronics.

Integrated, on-chip micro-supercapacitors are a promising technology in this recent field of electronics research. These devices offer high energy density and capacity and improved cycling abilities compared to conventional energy storage components. Whilst there has been increased study into their development, these devices possess poor performance when subjected to higher frequencies.

Using Graphene in Microsupercapacitors

Graphene is an intriguing material that has been widely explored in numerous industries for many innovative products. This material possesses advantageous properties for use as electrodes in next-generation micro-supercapacitors, in particular its high electrical conductivity and specific surface area.

Reduced graphene oxide and chemically exfoliated graphene have been used for these devices due to their high surface area and yield, but they are hindered by poor conductivity due to factors such as surface defects. Even after reduction, these materials are less conductive than pristine graphene. Additional problems occur with aggregation and restacking. The decreased effective surface area of these materials limits device cyclability and stability, making their use challenging.

A more suitable graphene-based material is multilayer graphene. Interlayer interactions in this material internalize the surface area. Multiple strategies have been explored to fabricate multilayer graphene, including the creation of artificially stacked graphene by incorporating spacer materials into its structure, such as metal-organic frameworks and carbon nanotubes. Researchers have fabricated materials with improved frequency responses and good charge/discharge rates.

Some studies have fabricated 3D multilayer graphene materials using chemical vapor deposition techniques, and these methods have created ultrafast micro-supercapacitors. However, the process of fabricating these materials involves complex synthetic procedures. Moreover, graphene’s electrical conductivity can become compromised.

Inducing turbostraticity increases inter-layer spacing due to multiple twists amongst the layers. This makes it easier for ions to access the sites within the material without the influx of foreign species. Studies have reported the successful fabrication of turbostratic graphene, but giving these materials a high degree of crystallinity, which improves their electrochemical performance, is still challenging.

The Research

In the study, the researchers have reported the development of highly crystalline graphene, which is free from defects. The material was used to fabricate an ultrafast microsupercapacitor in a facile process. The fabrication process used produced a turbostratic material with sp3 hybridized carbon. No doping impurities were present in the material.

The twisted structure of the material reduced inter-layer electronic interaction. Interlayer spacing was increased in the material, which consequently increased the multilayer graphene’s surface area. The all-solid-state micro supercapacitor produced by the authors displayed superior double-layer capacitance behavior. This behavior was retained even at extremely high scan rates and frequency responses.

More from AZoM: Analyzing Thin Crystals with an Electron Microscope

The surface morphology of the tMLG was analyzed using scanning electron microscopy. Additionally, Raman spectroscopy and mapping were utilized in the study. An optical profiler was used to measure the material’s thickness. Cyclic voltammetry was used to calculate the prepared device’s areal capacitance. The power density was calculated for the device.

To provide an insight into the nature of the prepared material, it was deposited onto a glass substrate for basic categorization. Transmission electron microscopy showed tMLG of varying thickness, and scanning electron microscopy revealed that the top surface of the material was smooth and intervened by wrinkles. A Raman 2D intensity map demonstrated that the percentage of turbostraticity is not dependent on thickness.

The power density of the ultrafast tMLG supercapacitor was two orders higher than conventional supercapacitors, demonstrating that the material can be considered appropriate for the construction of these devices. Additionally, power density was one order higher than comparable high-power electrolytic capacitors.

Overall, this study provides an interesting research direction for the development of ultrafast micro-supercapacitors for energy storage in next-generation electronic devices used for technological applications such as the Internet of Things. Turbostratic multilayer graphene can be used in high-frequency filter capacitors with good energy and power densities and specific capacitance.

Further Reading

Gupta, N, Mogera, U & Kulkarni, G.U. (2022) Ultrafast planar microsupercapacitor based on defect-free twisted multilayer graphene [online, pre-proof] Materials Research Bulletin 111841 | sciencedirect.com. Available at: https://www.sciencedirect.com/science/article/abs/pii/S0025540822001143

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.