Scientists from the Warsaw University of Technology in Poland have reported the production of hydrogen using plasma technology. The findings of their research have been published online in the journal Energies.

Study: Efficient Plasma Technology for the Production of Green Hydrogen from Ethanol and Water. Image Credit: petrmalinak/Shutterstock.com

Moving the World Toward a Post-Carbon Economy

Hydrogen energy has been widely proposed as a solution to address climate change and is a key technology that can help move the world to a post-carbon economy. Currently, there are no viable green hydrogen production technologies. Most commercial hydrogen is classed as “grey” hydrogen and is produced as a by-product of natural gas exploitation, amongst other fossil fuel sources.

Various methods can be used for the production of green hydrogen. It can be produced by splitting water or from raw biomass. Products derived from biomass such as bio-oils, bio-alcohols, and biogas can be used to produce this green energy source. Amongst these sources, bioethanol has shown promise as it can be easily obtained, transported, and stored and is safer for the environment and human health.

However, despite the environmental advantages of green hydrogen, producing this valuable product has disadvantages in terms of cost and the complexity of reactions needed to produce it. Moreover, in many conventional processes, coke and hydrocarbons are produced as by-products that are harmful to the environment. Green hydrogen production routes currently suffer from low efficiency. Significant research focus has been placed on the optimization of processes for producing green hydrogen from ethanol.

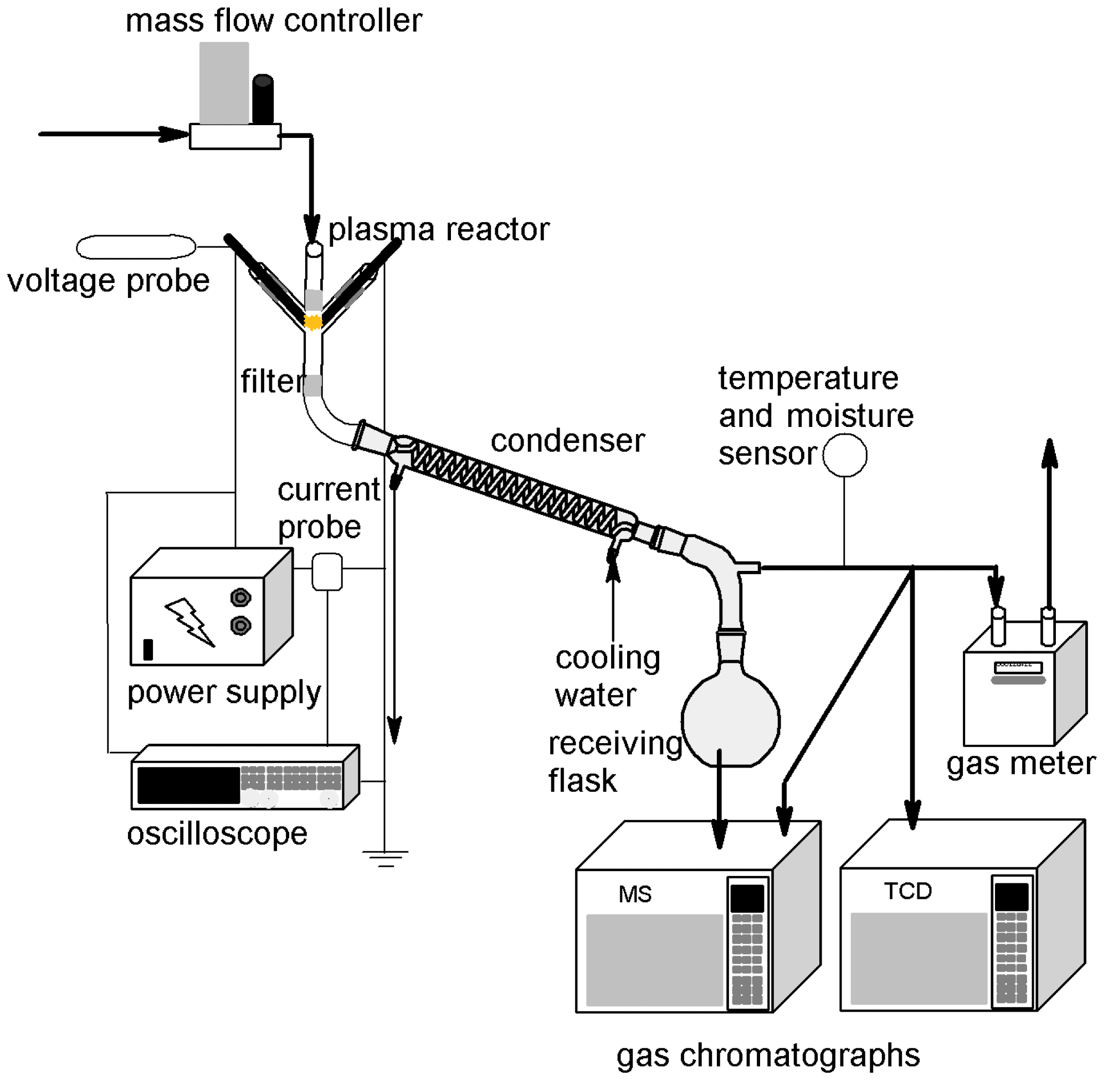

The scheme of the apparatus. Image Credit: Ulejczyk, B et al., Energies

Plasma Methods

Plasma technology has emerged as an attractive candidate for improving the efficiency of green hydrogen production. The chemical processes involved with synthesis can be controlled using plasma technologies. Various means such as microwaves and spark discharges can be used to produce the plasma necessary, making the technology highly versatile.

Several studies have been performed on using plasma technologies to produce hydrogen, with studies reporting different decomposition products from each process. Research has mostly been conducted using mixtures of water and ethanol, without gases that facilitate the formation of plasma.

The system used to supply power is an essential factor in plasma technologies. Studies have reported different results in the same reactor using different power supply systems. Despite the significant body of research, so far, the development of an economically viable technology for using ethanol to produce hydrogen has not been reported.

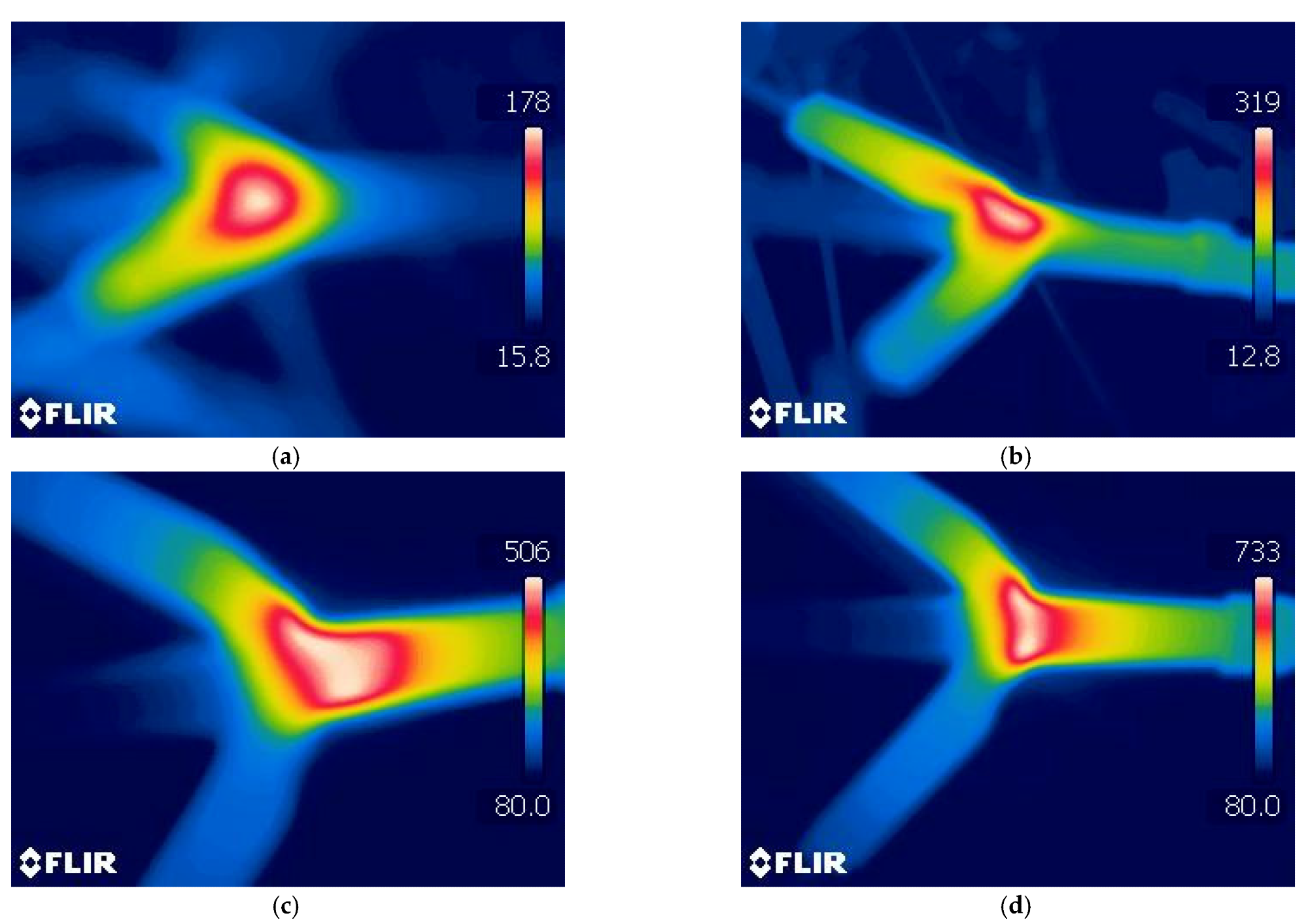

The reactor wall temperature for various discharge power: (a) 15.4 W, (b) 24.8 W, (c) 40.1 W, (d) 54.7 W. Feed flow—1 mol/h. Image Credit: Ulejczyk, B et al., Energies

The Study

The authors have focused on using the spark discharge process in their research. The research utilized small reactors for the process, opening the possibility for portable devices. Previous work by the authors on volatile organic compounds reported the suitability of the process for endothermic reactions due to the process’s generation of extremely high temperatures and the production of high-energy electrons.

As producing hydrogen from a mixture of ethanol and water is an endothermic reaction, the authors have stated that spark discharge should be a suitable method for producing this key energy resource. Another advantage of the proposed system in the research, according to the authors, is that the spark reactor is attractive for the periodic feeding of fuel cells, as the process can be turned on or off without the need for actions such as heating or purging.

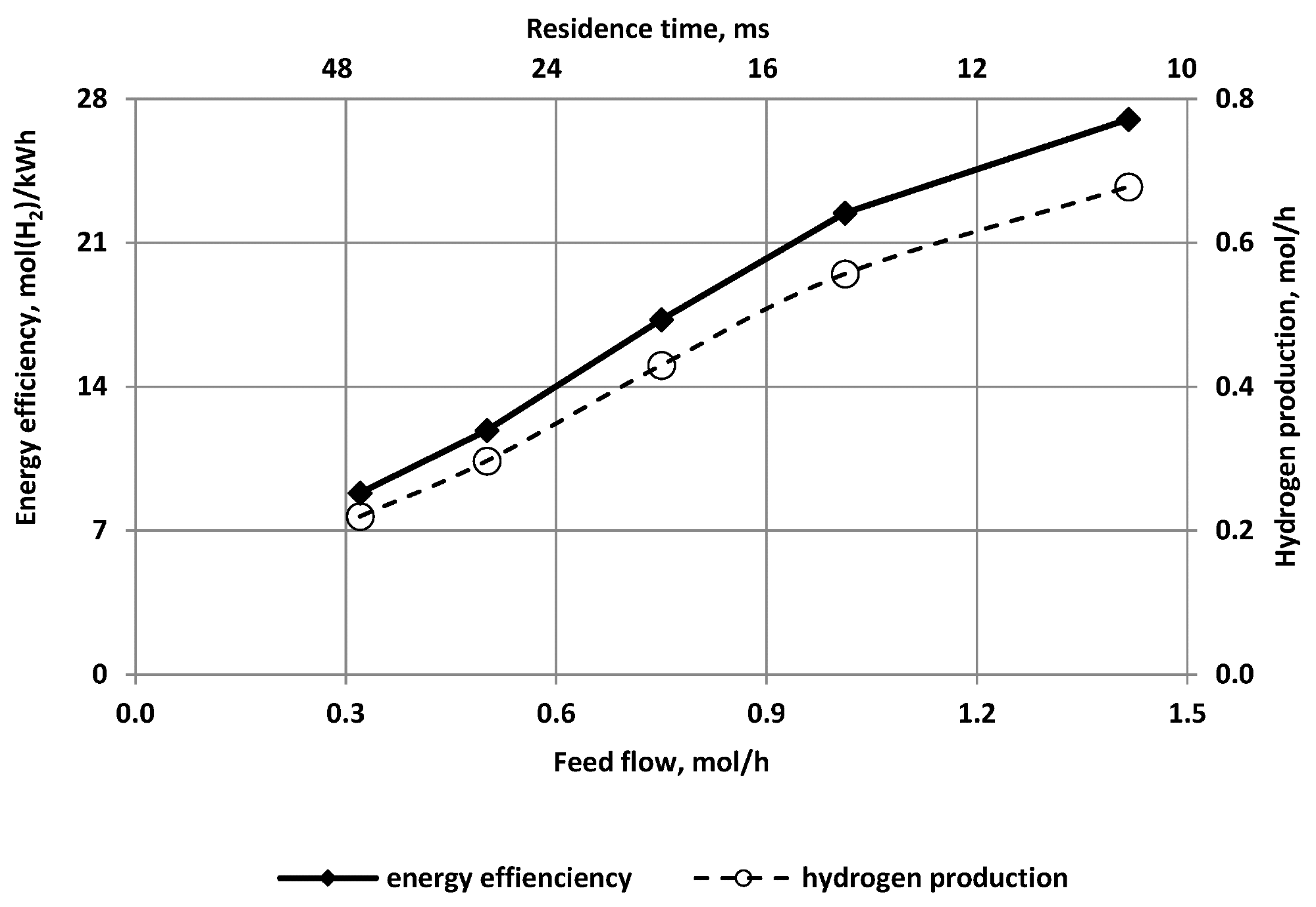

In the process, hydrogen, carbon dioxide, carbon monoxide, ethylene, methane, and acetylene were produced, as well as coke. Energy efficiency of the process reached 36% of the theoretical energy efficiency. Relatively high ethanol conversion was achieved (63%), and using the process it was possible to reach 95% under optimal conditions. However, higher energy consumption was needed, and the energy efficiency of hydrogen production was reduced. Increasing the feed stream and discharge power increased the hydrogen production efficiency.

Under all tested conditions, the hydrogen concentration was favorable, ranging from 57.5%-61.5%. This is despite the changing hydrogen production efficiency under different process conditions. Based on the evaluation of the proposed system, the authors have stated that the spark discharge reactor can feed fuel cells with fluctuating power loads.

The effect of the feed flow on the energy efficiency and hydrogen production. Discharge power—25 W. Image Credit: Ulejczyk, B et al., Energies

Carbon monoxide was the main gaseous product in the spark discharge reactor. By increasing carbon monoxide conversion in the water-gas shift reaction, the process’s hydrogen production efficiency could be increased, according to the authors. Moreover, the by-products such as carbon monoxide and hydrocarbons do not interfere with the spark discharge process, and their oxidization produces heat which will heat the cell.

Overall, this study provides evidence for the potential of the spark discharge process as a suitable green method for producing hydrogen from ethanol, which will help realize the potential for hydrogen to replace fossil fuels and mitigate the environmental impact of human activities.

Further Reading

Ulejczyk, B et al. (2022) Efficient Plasma Technology for the Production of Green Hydrogen from Ethanol and Water [online] Energies 15(8) 2777 | mdpi.com. Available at: https://www.mdpi.com/1996-1073/15/8/2777

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.