Panacol has developed new UV curable masking materials for industrial processes. These masking materials are part of the Vitralit® MASK product line. They can be easily applied, cured in seconds by exposure to UV light, and then removed by a simple peel, or for those masks with higher adhesion, hot water dip and peel.

Image Credit: Panacol

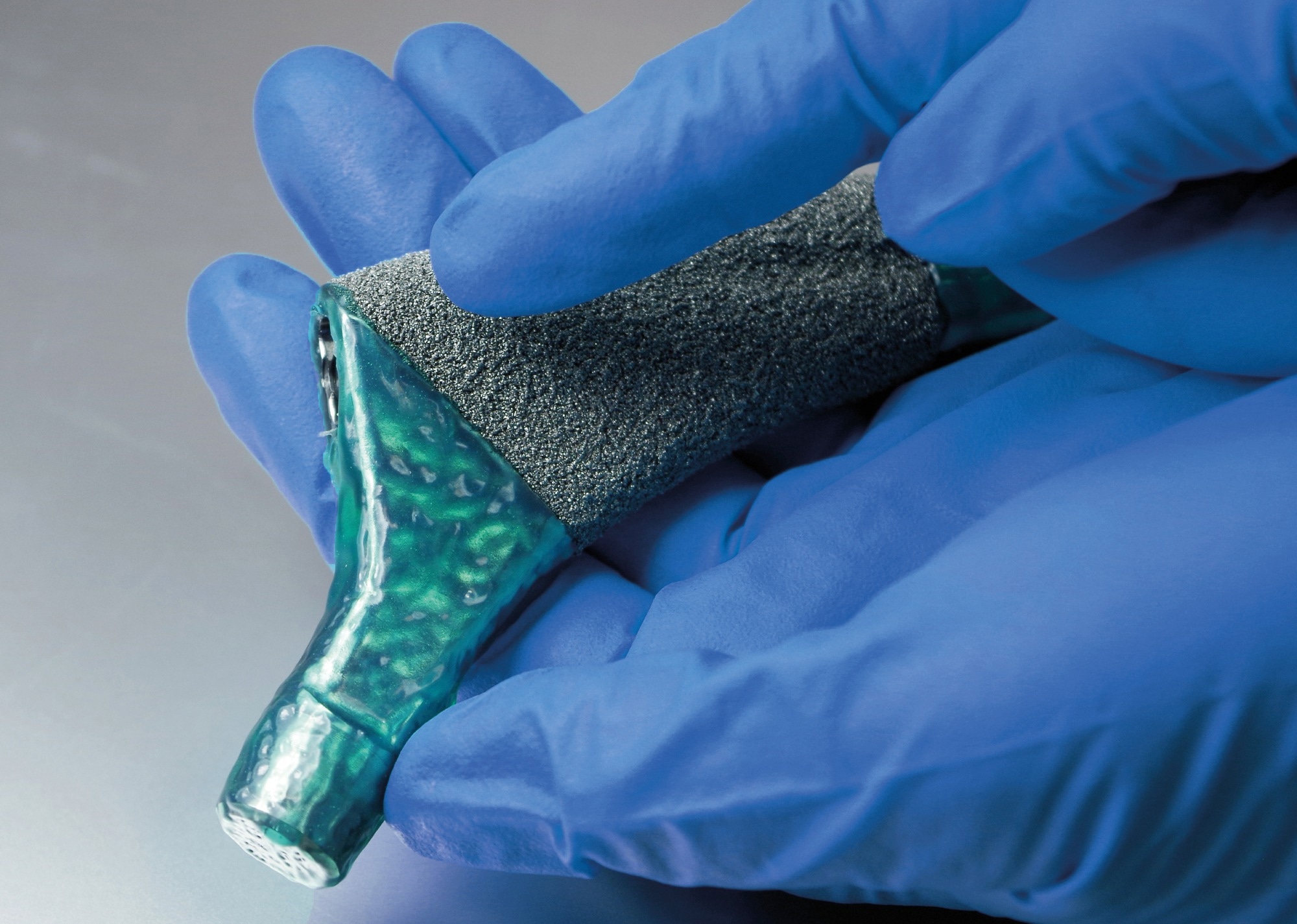

UV mask material is typically used in high value component fabrication that involves processes for surface enhancement. These processes may include acid cleaning, grit blasting, or shot peening. Component surfaces or internal cavities may need to be insulated from these processes for reasons of functionality. Masking materials are applied as temporary barriers, that are subsequently removed from the completed component after processing. Typical applications include the manufacture of turbine components, orthopedic devices or prosthesis, and other industrial component processes such as the coating of circuit boards and plastics.

The UV masking material is derived from light curable adhesive technology. Panacol’s family of UV light curable mask materials are solvent-free and can be easily applied and cured in seconds with a UV light source. The curing system may be broad spectrum UV or LED in in wavelengths of 365 or 405nm.The uncured liquid mask can be applied on components by syringe, dip, or spray. The masks are available in many viscosities to accommodate a wide variety of component configurations and applications. Both high and low viscosity masks from Panacol can be easily dispensed through spray valves onto larger surfaces. All Vitralit® MASK materials provide uniform and consistent protection from high impact particulates, hot acids, alkali solutions, plating, and paint. Vitralit® UV masks are available in green color to provide higher contrast for better visual inspection.

Removal of Panacol UV mask materials such as Vitralit® MASK 20107 or 20109 is accomplished by a simple peel, or a hot water dip and peel. A selection of Panacol UV masks, such as the new Vitralit® MASK 20116, have extremely high surface adhesion for the most rigorous processing. These UV masks are best removed through incineration. Panacol UV masking materials do not leave surface residue after peeling or incineration.

About Panacol

Panacol-Elosol GmbH was founded in 1978 as a German subsidiary of the Swiss Panacol AG in Frankfurt. In 2008, Panacol was acquired by Munich-based Dr. Hönle AG, a leading global supplier of industrial UV equipment technology. As a member of the Hönle Group, Panacol is a knowledgeable and reliable provider of adhesives, coatings, and UV/LED curing equipment for OEM and contract manufacturers around the world.