Reviewed by Mila PereraSep 16 2022

As photovoltaic technology continues to advance, its promise as a useful photovoltaic technology has become evident. As such, a research team has been reviewing current perovskite photovoltaic modules to increase the potential of perovskite solar cells.

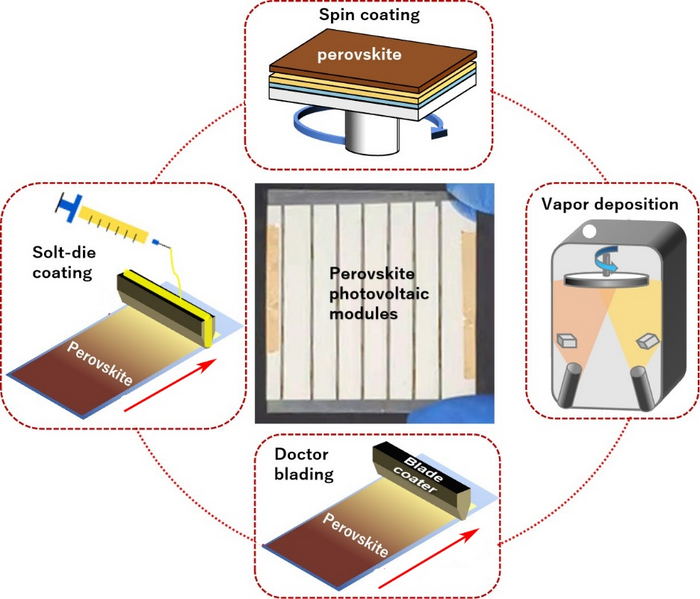

The research team summarized the advances of perovskite photovoltaic modules with particular attention paid to the coating methods, including spin coating, doctor blading, slot-die coating, spray coating, inkjet printing, soft-cover deposition and vapor deposition. Image Credit: Nano Research Energy

The research team summarized the advances of perovskite photovoltaic modules with particular attention paid to the coating methods, including spin coating, doctor blading, slot-die coating, spray coating, inkjet printing, soft-cover deposition and vapor deposition. Image Credit: Nano Research Energy

With this promising technology comes a requirement for high-quality perovskite films for large-area solar modules. The study will help researchers who are seeking to advance the commercialization of perovskite photovoltaic modules.

On August 24th, 2022, the team, including researchers from the Chinese Academy of Sciences, Nanjing University of Posts and Telecommunications, Changzhou University, University of Sialkot, and Hangzhou Dianzi University, published its findings in the journal Nano Research Energy.

The group’s research focused on the coating techniques applied to perovskite solar modules and reviewed and summarized the modules' current developments. Spin coating, slot-die coating, doctor blading, inkjet printing, spray coating, soft-cover deposition, and vapor deposition were some of the techniques studied.

The team also studied how the high-quality, large-area perovskite films grow. Their research covers potential and future development directions for perovskite photovoltaic modules.

Optoelectrical characteristics of perovskite solar cells are particularly advantageous for photovoltaic applications. Compared to the silicon solar cells now in use, perovskite solar cells are less expensive and easier to make.

Academics and businesses are, therefore, acutely aware of these perovskite solar cells. Perovskite solar cells, in particular, have high efficiency and may be produced using inexpensive methods.

A validated laboratory-scale power conversion efficiency of 25.7% has been attained by perovskite solar cells. The perovskite solar cells show significant promise for future commercialization due to their high power conversion efficiency and inexpensive cost.

While it is possible to manufacture these high-efficiency perovskite solar cells with an area of less than 0.1 cm2, it is difficult for researchers to enlarge the perovskite films for larger photovoltaic modules properly.

Expanding the high-quality films from small to large-area modules is challenging for researchers. When employed in bigger perovskite photovoltaic modules, the excellent power conversion efficiency that small-area perovskite solar cells can attain is dramatically reduced. It is challenging to create these perovskite solar cells for widespread commercial application unless this issue is solved.

For manufacturing large-area perovskite photovoltaic modules towards industrialization, lots of issues need to be solved, such as the relatively low efficiency of large-area perovskite photovoltaic modules, the preparation of large-area and high-quality perovskite films, and the design of interconnected sub-cells to composite modules.

Liang Chu, Professor, Hangzhou Dianzi University

The first stage is the ability to deposit large-area perovskite films with good uniformity and reproducibility.

Without a standard industrial scale, the methods for depositing large-area perovskite films are varied. These coating techniques are crucial as the thickness, crystallinity, surface roughness, and compactness of those films directly impact the perovskite films’ absorption, charge production, separation, and device performance.

The research team investigated the potential that perovskite photovoltaic modules might hold for future commercial applications by studying and evaluating the various coating techniques and finding their limitations.

The team identified numerous development directions with the intention of eventual commercialization. To improve the effectiveness of perovskite solar modules, they advise that researchers continue to develop coating techniques for large-area, high-quality perovskite films.

Additionally, they recommend simultaneously altering the surface and subsurface layers to passivate the perovskite flaws in perovskite solar modules. These interface layers resolve the corrosive reaction problem. The final piece of advice from the team is for researchers to consider stability strategies that have been used successfully for small-area perovskite solar cells.

These strategies could greatly improve the stability of large-area perovskite photovoltaic modules.

Liang Chu, Professor, Hangzhou Dianzi University

The study was financially supported by the National Natural Science Foundation of China. The team included Liang Chu, Yue Zang, and Wensheng Yan from Hangzhou Dianzi University; Shuaibo Zhai from Nanjing University of Posts and Telecommunications; Waqar Ahmad from the University of Sialkot; Jing Zhang from Changzhou University; and Yongfang Li from Chinese Academy of Sciences.

Journal Reference

Chu, L., et al. (2022) High-performance large-area perovskite photovoltaic modules. Nano Research Energy. doi.org/10.26599/NRE.2022.9120024.