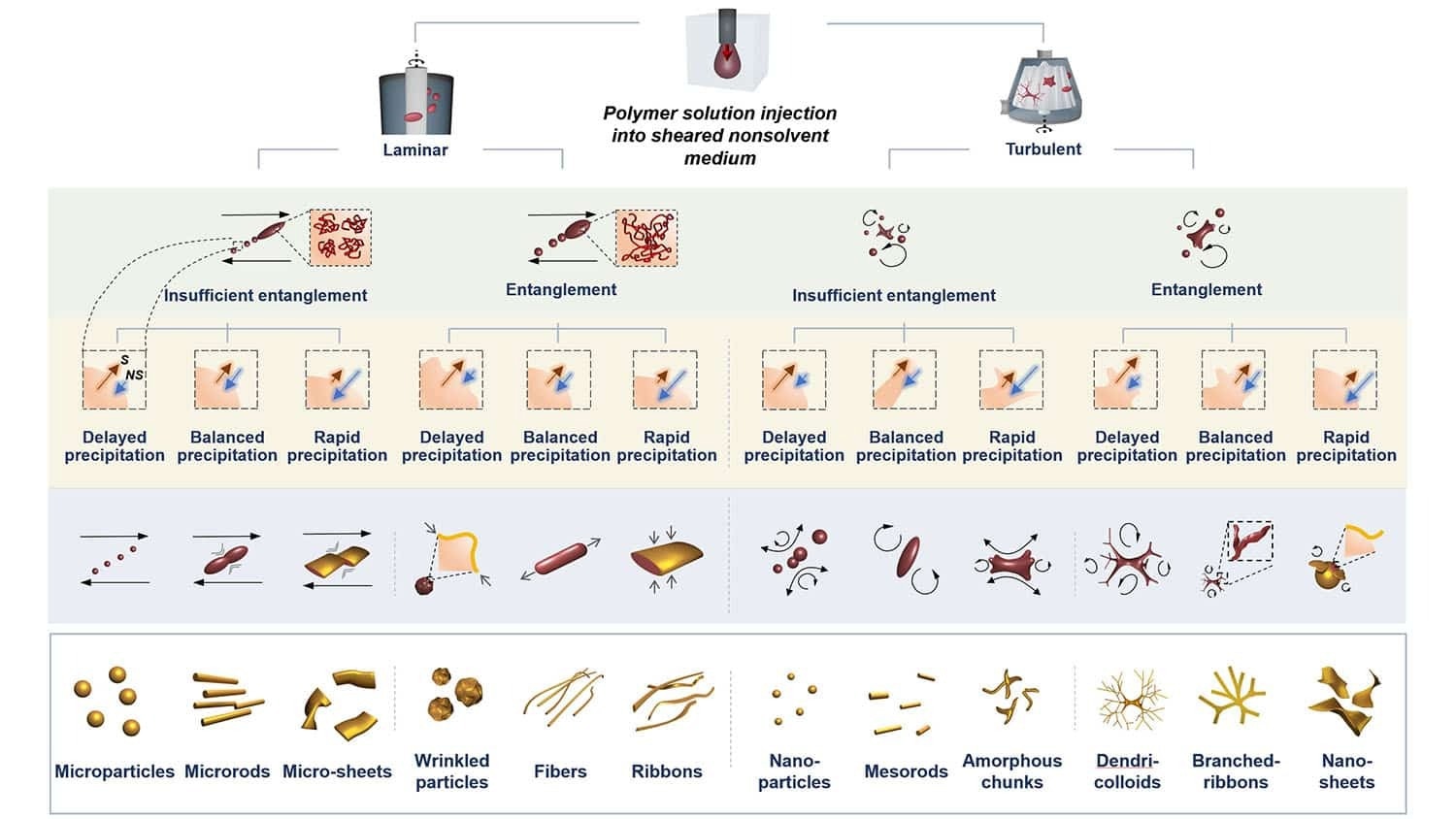

This image shows how the interplay of multiple mechanisms can be used to form 12 discrete polymer morphologies by modifying the liquid process parameters. Image Credit: North Carolina State University

Orlin Velev adds, “For example, the nanosheets can be used in designing better batteries, whereas dendricolloids—branching networks of polymer fibers that have exceptionally high surface area—can be used in environmental remediation technologies or creation of novel lightweight metamaterials.”

The different morphologies were created through a widely recognized process called polymer precipitation. A polymer is dissolved in a solvent to produce a polymer solution in this process. Then, the polymer solution is introduced into a second liquid, causing the polymer to recombine as soft matter.

The scientists identified how to accurately control the structure of the resulting polymer soft matter by modifying three sets of parameters during the manufacturing process.

The shear rate, which relates to how rapidly the liquids are stirred when the two liquids are combined, is the first set of parameters. The concentration of the polymer in the polymer solution is the second set of parameters. The final set of parameters is the composition of the solvent used to dissolve the polymer and the composition of the liquid to which the polymer solution is added.

We identified the critical parameters that affect the final morphology of the polymeric materials, which in turn gives us a great deal of control and versatility. Because we now understand the role of each of these factors and how they all influence each other, we can reproducibly fine-tune the polymeric particle morphology.

Rachel Bang, Study First Author and PhD Graduate, North Carolina State University

“Even though we have demonstrated how to produce a dozen different morphologies, we are still in the early stages of exploring all of the possible outcomes and applications,” Velev notes.

Scientists have already shown that dendricolloids could be used to develop membranes for growing live cells as well as hydrophobic or hydrophilic coatings. The investigators also collaborated with others to show that the nanosheets have the potential to be used as more effective separators in lithium-ion batteries.

The technique can also be used with a variety of natural biopolymers, such as plant proteins, and it could be used to support a variety of applications, such as the development of plant-based meat analogs, which requires precise control of protein particle morphologies at multiple length scales. In addition, because our technique is based on mixing liquids using conventional mixers, it can be easily scaled up for practical manufacturing.

Simeon Stoyanov, Study Co-Author and Professor, Singapore Institute of Technology

Simeon Stoyanov is also associated with Wageningen University in the Netherlands.

Velev adds, “We are currently working with food science researchers to determine how protein microrods could be used to control the texture of some food products. And we are also working with collaborators to explore how our technique can be used to produce biopolymer-based materials for use in biodegradable soft electronics. We are open to working with additional collaborators to explore potential applications for the polymers and biopolymers across all of these morphologies.”

NC State has provided or has awaiting patents on the shear fabrication of microrods, nanofibers, and dendricolloids, as well as their use in electrochemical energy sources.

The research was published in the journal Advanced Materials. The study was also co-authored by Sangchul Roh and Austin Williams, former Ph.D. students at NC State.

The research was funded by the National Science Foundation’s Nanomanufacturing Program under grant CMMI-1825476. The study also received additional support from NSF under grants EFMA-2029327 and CMMI-2134664.

Journal Reference

Bang, R. S., et al. (2023). Fluid Flow Templating of Polymeric Soft Matter with Diverse Morphologies. Advanced Materials. doi.org/10.1002/adma.202211438.