A new release of Volume Graphics’ advanced CT scan data inspection software suite provides a modernized user interface, a new machine-learning-based segmentation method, and dedicated capabilities for inspecting batteries—among other useful enhancements.

Improving traditional and lithium-ion battery safety, longevity and reliability are possible with advanced CT-data analysis, which quantifies interior material characteristics that reflect chemical states and impact mechanical features such as walls and joints. Image Credit: Volume Graphics

Improving traditional and lithium-ion battery safety, longevity and reliability are possible with advanced CT-data analysis, which quantifies interior material characteristics that reflect chemical states and impact mechanical features such as walls and joints. Image Credit: Volume Graphics

CT-data analysis software for inspection has a quality role in nearly every industry that has critical parts and processes that need monitoring for faults and variations. These include automotive, aerospace and electronics, among others. Volume Graphics’ software tracks, analyses, and visualizes porosity/inclusions, delaminations, fiber or grain orientations, deformations and areas of low density and weakness. It is used to compare the “as-designed” and “as-manufactured” product to ensure compliance to specifications and intended performance.

Increasingly, CT-data analysis is being used across engineering disciplines to loop virtual test and real-world measurement results back to design, simulation and forward to prototyping, First Article Inspection (FAI) and manufacturing—improving the accuracy and reliability of each program stage.

Here are some of the highlights in version 2023.1 of Volume Graphics’ leading CT data analysis software suite (which includes VGSTUDIO MAX, VGSTUDIO, VGMETROLOGY, VGinLINE, and myVGL).

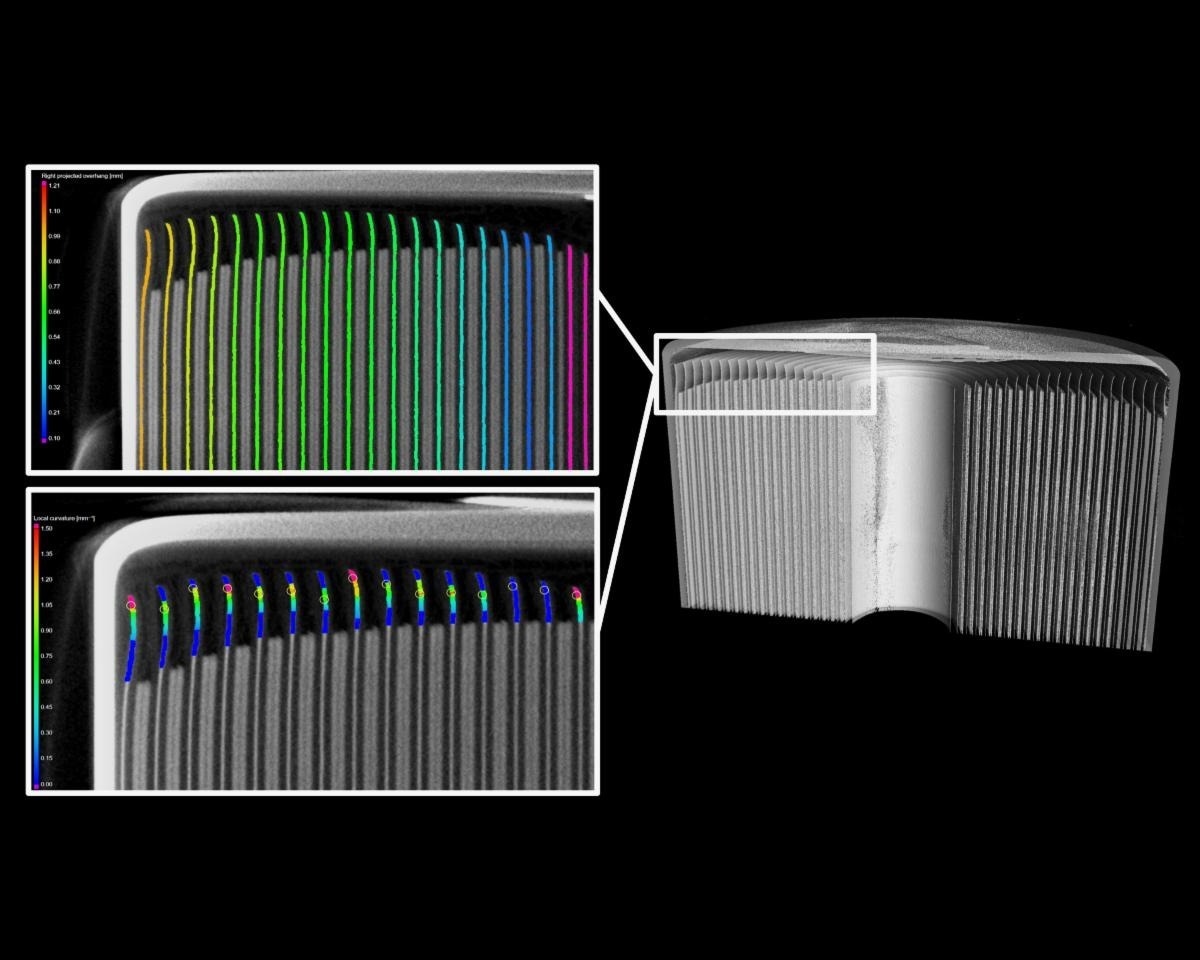

Enhanced Battery Inspection for 2D Anode Overhang Analysis.

The software’s new battery inspection feature provides dedicated functionality for easy measurement and visualization of battery properties. It provides improved 2D tolerance checking of anode overhang, curvature, thickness and anode exit angle, along with the ability to track shape-following lengths and adjacent electrode counts. Imprecise anode overhang can cause thermal runaway and severe failures, along with limiting electrical performance. The insights that CT-data analysis provides allows research institutions and battery manufacturers to measure voids and particle sizes during the research and development phase, detect delamination and contamination during cell manufacturing, analyze electrical connections and electrolyte fill levels, and provide many other quality-assurance functions that were once impractical or even impossible to perform.

Paint & Segment Feature Uses AI/Machine Learning to Optimize and Speed-Up Fault Detection.

Segmentation is an important function in VGSTUDIO MAX—helping compare and reconcile as-designed models to the as-manufactured part; identifying, classifying, localizing and segmenting challenging fault areas for analysis and template development; and finally, playing a role in automating design, simulation and production feedback loops and inline inspection. In Paint & Segment, users can (manually) “paint” sample regions to train the machine learning algorithm for future automated tasks. Users can then save the just-created segmentation model and apply it to similar components and datasets. In combination with Volume Graphics’ macro framework, the software upgrade enables very complex problems to be solved in fully-automatic analysis mode. The new functionality is extremely useful in life sciences, paleontology and archeology, material science and battery inspection.

Ribbon User Interface Makes Inspection Easier.

Dedicated home tabs in version 2023.1 facilitate easy access to the main application functions, now better named and grouped into ribbon tabs. Contextual tabs make it easier to work with specific elements and the new “reporting” tab includes all reporting-related functions, including the powerful built-in report editor. Access to advanced customization capabilities, a preview gallery for recently used files, and a shortcut editor increases the productivity users can now bring to bear on quality-assurance challenges in both R&D and industrial applications.