Reviewed by Lexie CornerMar 7 2025

A research team at the Convergence Research Center for Solutions to Electromagnetic Interference in Future-mobility (SEIF) at the Korea Institute of Science and Technology (KIST) has created a novel polymeric material with high recyclability and self-healing properties.

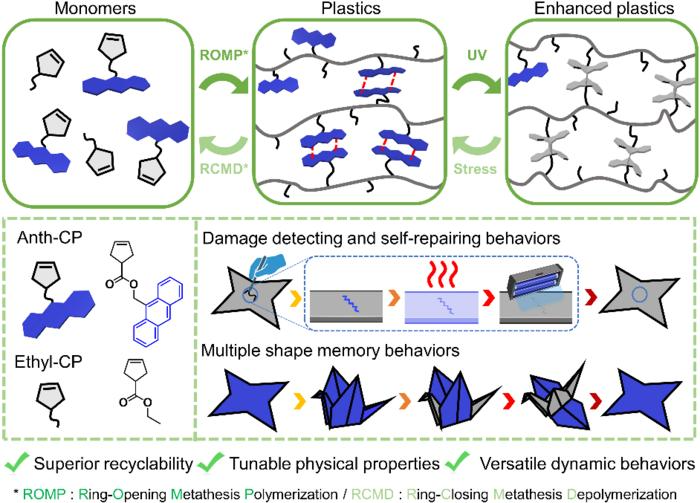

Schematic illustrations of smart plastic materials capable of damage detection, self-healing, and multi-shape memory properties. Image Credit: Korea Institute of Science and Technology

Schematic illustrations of smart plastic materials capable of damage detection, self-healing, and multi-shape memory properties. Image Credit: Korea Institute of Science and Technology

A research team at the Convergence Research Center for Solutions to Electromagnetic Interference in Future-mobility (SEIF) at the Korea Institute of Science and Technology (KIST) has created a novel polymeric material with high recyclability and self-healing properties.

Plastics are polymeric materials made up of long chains of molecules called monomers. They are widely used in everyday life and industry due to their lightweight, high strength, and flexibility. However, plastic pollution has become a major environmental issue, with an estimated 52 million tons of plastic waste generated annually.

Researchers have focused on developing environmentally friendly polymeric materials, but most existing solutions have complex production processes or are difficult to separate from other polymers during waste disposal.

The team created a unique pentagonal ring-structured molecule that can convert freely between monomers and polymers. It also enables dynamic covalent exchange processes in response to heat, light, and mechanical forces. This molecule helps create polymeric materials with varying characteristics, from rubber-like flexibility to glass-like rigidity.

The new polymer is easy to handle because it emits fluorescence at damaged sites, allowing real-time damage detection. It also self-heals when exposed to heat and light. When discarded, the material preferentially depolymerizes into its monomers, even when mixed with standard plastics. The recovered monomers can then be used to regenerate the polymer with its original properties, improving sustainability and recyclability.

This material also exhibits dynamic changes in thermal, mechanical, and optical properties when exposed to heat, light, and mechanical forces. As a protective coating, it outperforms standard epoxy coatings, with three times the hardness and more than twice the elastic modulus.

Exposure to ultraviolet light increases molecular connections, enabling the material to retain certain shapes. This form memory capability opens possibilities for smart clothing, wearable technologies, and advanced robotics.

With high mechanical strength, damage resistance, self-healing, damage detection, and selective recyclability, this polymeric material offers a viable alternative for reducing the economic costs of sorting and processing mixed plastic waste. Additionally, it can replace industrial coatings, lowering maintenance costs and reducing environmental pollution.

This research introduces a new approach to designing materials with autonomous functionalities, such as damage detection and self-healing, while overcoming the thermal and mechanical limitations of recyclable plastics derived from pentagonal ring monomers. We are striving to pioneer the market for eco-friendly functional coatings that require minimal maintenance and generate no waste.

Dr. Tae Ann Kim, Principal Researcher, Soft Materials Research Group, Korea Institute of Science and Technology

This research was funded by the National Research Council of Science and Technology (NST) grant (CRC22033-230) of the Ministry of Science and ICT (Minister Sang-im Yoo) and the Nano & Material Technology Development program (RS-2024-00448445) of the National Research Foundation of Korea.

Journal Reference:

Lee, J. et. al. (2025) High-Performance Dynamic Photo-Responsive Polymers With Superior Closed-Loop Recyclability. Advanced Functional Materials. doi.org/10.1002/adfm.202414842