A hydrogen-free, high-speed coating nearly doubles OLED lifetime and could accelerate the future of flexible displays.

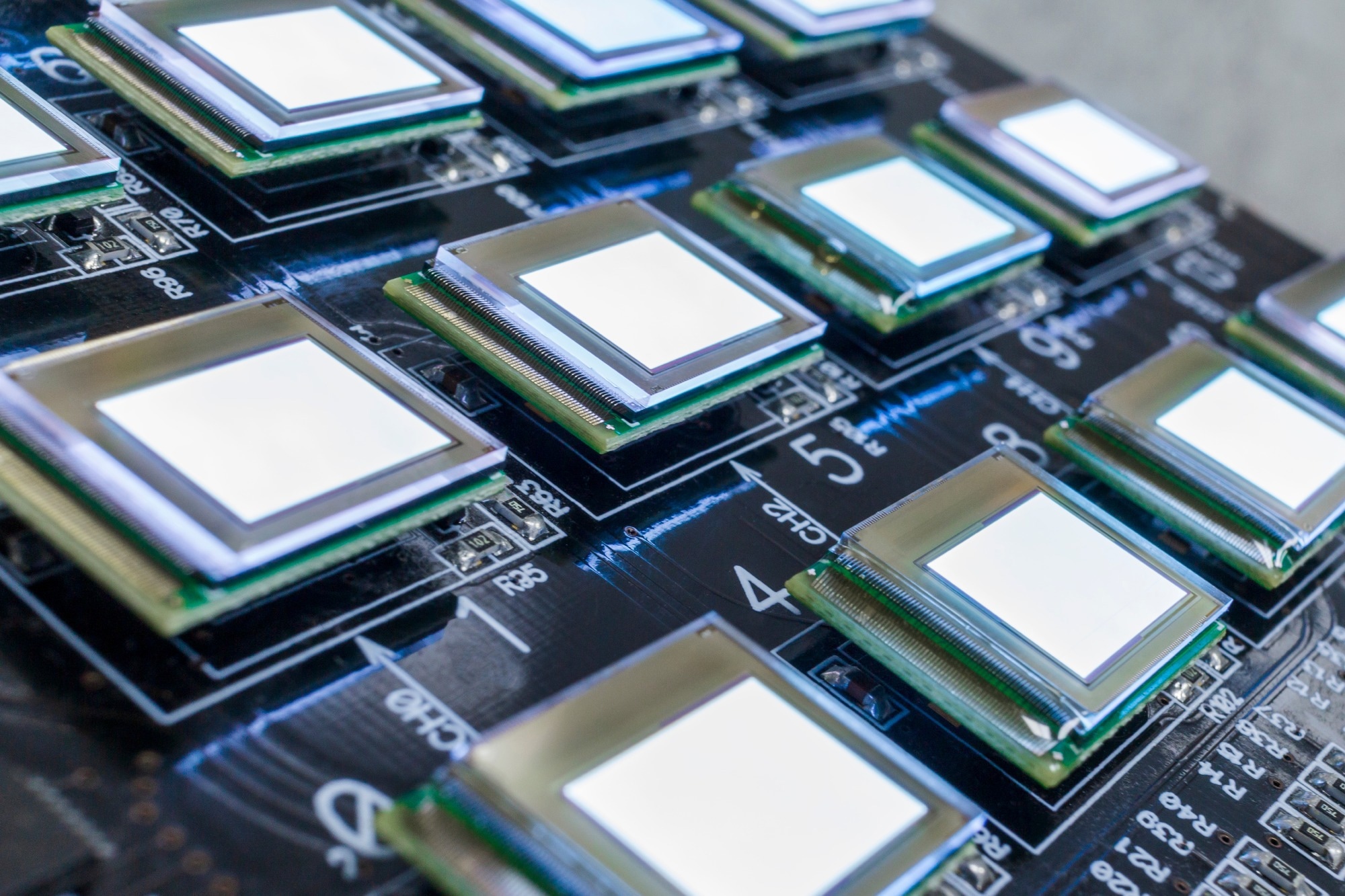

Study: Filtered Cathodic Vacuum Arc Deposition for Inkjet-Printed OLED Encapsulation. Image Credit: Titolino/Shutterstock.com

Study: Filtered Cathodic Vacuum Arc Deposition for Inkjet-Printed OLED Encapsulation. Image Credit: Titolino/Shutterstock.com

Researchers have reported a faster method for sealing flexible organic light-emitting diode (OLED) displays. Writing in Materials, the group demonstrates that Filtered Cathodic Vacuum Arc (FCVA) deposition can produce dense, hydrogen-free alumina (Al2O3) barrier films at approximately 15 nm per minute, almost three times faster than atomic layer deposition (ALD).

ALD has long been valued for producing uniform, conformal films. But its layer-by-layer, cyclic growth mechanism inherently limits throughput. Just as importantly, hydrogen incorporation during ALD-based oxide growth is difficult to eliminate, and hydrogen diffusion into oxide thin-film transistor (TFT) backplanes can destabilize electrical performance over time.

FCVA takes a different approach.

By generating a high-density plasma from an aluminum cathode and filtering it magnetically to remove droplets and neutral particles, the process delivers high-purity, hydrogen-free species to the substrate. Under optimized conditions, the system operated within a tunable deposition range of approximately 10-20 nm/min, with ~15 nm/min achieved in this study.

Get all the details: Grab your PDF here!

The researchers deposited 100 nm-thick Al2O3 films at 80 °C using an argon–oxygen gas mixture and integrated them into a multilayer thin-film encapsulation (TFE) stack: a silicon oxynitride base layer, a 12 µm inkjet-printed acrylic buffer, and a 100-nm FCVA-Al2O3 capping layer.

Compared with ALD films of similar thickness, FCVA films showed smoother surfaces (average roughness 0.111 nm versus 0.314 nm).

X-ray diffraction confirmed that both films were amorphous, an advantage for moisture barriers because amorphous oxides lack grain boundaries that can act as diffusion pathways.

Water vapor transmission rate (WVTR) measurements at 40 °C and 90 % relative humidity had observable differences: 1.2 × 10-4 g/m2/day for FCVA-Al2O3 versus 1.6 × 10-3 g/m2/day for ALD films, roughly an order of magnitude improvement.

However, the authors note that a single-layer FCVA-Al2O3 film alone does not fully meet OLED barrier requirements. The organic buffer layer remains essential, forming a hybrid laminated structure that blocks moisture more effectively than any single layer alone.

The FCVA films also exhibited tunable residual stress ranging from approximately −140 MPa to −55 MPa, enabling stress balancing across the stack. This is an important factor for flexible displays, where cracking or delamination can limit device lifetime.

Encapsulation to Protect the Electronics Beneath

Encapsulation must protect not only the light-emitting layer but also the oxide TFT backplane that drives it. To test this, the team compared electrical characteristics before and after FCVA encapsulation.

The results showed only minimal changes: Threshold voltage shifted slightly from 1.08 V to 1.10 V, carrier mobility remained stable, and subthreshold swing improved marginally.

The absence of significant negative voltage shifts - commonly associated with hydrogen-related effects - supports the conclusion that the hydrogen-free FCVA process avoids introducing detrimental species into the TFT channel.

The data also suggest that plasma energy in the optimized process is sufficiently controlled to prevent structural damage.

Extending Device Lifetime

The researchers then tested full inkjet-printed OLED devices under accelerated aging conditions of 85 °C and 85 % relative humidity.

Devices protected with the FCVA-based multilayer structure operated for 300 hours, nearly double the lifetime of reference devices without the FCVA-Al2O3 layer.

On top of this, optoelectronic performance remained consistent before and after encapsulation.

Although a slight increase in current efficiency was observed, the authors caution that it is best interpreted as a modest improvement rather than definitive evidence of enhanced light extraction.

Industrial Potential And Next Steps

The results suggest that FCVA-based Al2O3 can improve deposition rates, enhance barrier performance relative to ALD, and improve compatibility with oxide TFT backplanes, all without hydrogen incorporation.

At the same time, the researchers are careful not to overstate readiness for mass production. Scaling the technology for large-area flexible displays may require multi-source configurations and linear scanning mechanisms to ensure uniform coverage.

Further work is also needed to quantify hydrogen content more precisely, assess long-term TFT bias-stress stability, and conduct systematic LT50 lifetime evaluations.

Even so, the study outlines a credible route toward faster, hydrogen-free encapsulation for flexible OLED manufacturing, addressing both throughput and reliability in a single process step.

Journal Reference

Gao, Z. et al. (2026). Filtered Cathodic Vacuum Arc Deposition for Inkjet-Printed OLED Encapsulation. Materials, 19(3), 638. DOI: 10.3390/ma19030638

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.