May 11 2009

The new four-flight BUSS MX Kneader made in Switzerland by Buss AG, Pratteln, has proven highly successful in compounding applications ranging far beyond the original goal of HFFR cable compounds. BUSS has therefore expanded its applications to cover practically all high-fill temperature and shear sensitive compounds.

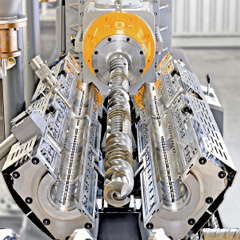

This open view of the high-performance BUSS four-flight MX 105-15

Kneader reveals the optimized zone-for-zone processing section

Source: Buss AG, Pratteln.

This open view of the high-performance BUSS four-flight MX 105-15

Kneader reveals the optimized zone-for-zone processing section

Source: Buss AG, Pratteln.

For the same machine size, throughput of these innovative high-performance MX kneaders is two and a half times that of previous models. Decisive for this is the bigger processing section, optimized zone-for-zone, for better mixing with less energy input, and the powerful new drive system enabling speeds up to 750 rpm without exceeding product temperature limitations. The original application of the BUSS MX Kneader family was for compounding HFFR cable compounds containing up to 70 % by weight of metal hydroxide.

Through application-specific optimizations and extensions, BUSS has been able to expand its applications in good time for presentation at the NPE 2009. At this leading US trade fair, held from June 22 to 26 in Chicago, the BUSS booth 83039 (North Building, hall B) will show an MX Kneader for HFFR cable compound production. Located only half an hour away in Carol Stream IL, is Buss Inc., USA. This company has been responsible for BUSS sales and service throughout the NAFTA since almost forty years.

Depending on application, MX Kneaders can be fitted with several material feeds, discharge extruder or melt pump, automated screen changer, and various types of pelletizer including air-water pelletizing. By tailored configuration in teamwork with the BUSS application engineers, the modular BUSS MX Kneader can be customized for producing:

- Conductive compounds into which a high content of special carbon black, carbon fibers or carbon tubes/nanotubes have to be worked without breaking down the structure. These are used e.g. for cable sheathing, conductive automobile body parts suitable for powder coating, or antistatic plastics in the packaging, electrical and electronics industries.

- Masterbatches, above all containing up to 50% by weight of low-density carbon black,

- High-fill compounds with up to 85 % by weight of typical fillers such as chalk or talcum, china clay or wood dust.

The high efficiency of MX Kneaders substantially reduces processing costs for all these applications, whether due to the much higher throughput, or the investment savings, space and operating cost savings enabled by using a smaller MX Kneader for the same throughput.

BUSS CEO Beat Sturzenegger on the extended applications of this highperformance Kneader: "The wider application range of our MX Kneader family will further consolidate our market positioning as technology leader in temperature and shear sensitive plastics compounding. Most of the products made with our MX Kneaders are used for specialty niche applications that are less prone to the global recession now affecting other markets. So with this high-performance Kneader at the NPE 2009, we are unveiling just the right product at just the right time".