Jun 18 2009

Since the discovery of carbon nanotubes in the early 1990s, nanotubes and nanowires have been the focus of scientific and technological interest. It has since also proved possible to produce these tiny structures from materials other than carbon. Possible applications range across many areas, including microelectronic circuits, sensor technology, and special fibre optics and light-emitting nanotubes for displays. A team of researchers led by Wolfgang Tremel at Johannes Gutenberg University Mainz have now developed a new technique for producing tin disulfide nanotubes. According to the report published in the journal Angewandte Chemie, the scientists have found a way of 'growing' SnS2 tubules from a metal droplet.

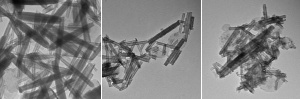

TEM images of nanotubes obtained when bulk SnS2 (a) and bulk SnS (b, c) were used as precursors for the synthesis of SnS2 nanotubes. ©: Angewandte Chemie, Wiley-VCH-Verlag

TEM images of nanotubes obtained when bulk SnS2 (a) and bulk SnS (b, c) were used as precursors for the synthesis of SnS2 nanotubes. ©: Angewandte Chemie, Wiley-VCH-Verlag

It is not a new concept that metal sulfides with a lamellar structure will form nano-tubes. These are currently employed in medical devices, as fibres with extremely high tensile strength, in hydrogen storage, for rechargeable batteries, in catalysis, and in nanotechnological applications. However, a major problem associated with the synthesis of sulfide-based nanotubes is that high temperatures are required for the planar structures to be induced to bend to form cylinders. In addition, these unstable intermediate products must be trapped. This is nearly impossible in the case of tin disulfide, as the nanotube collapses already at significantly lower temperatures.

The team of researchers at Mainz University therefore implemented an alternative method for the production of tin disulfide nanotubes: They first used the vapour-liquid-solid (VLS) process, a technique more commonly used to produce semicon-ductor nanowires. Bismuth powder is combined with tin disulfide nanoflakes, and the mixture is heated in a tube furnace under an argon gas flow. The product of the reaction is deposited at the cooler end.

Nanodroplets of bismuth are formed in the furnace, and these act as local collec-tion points for tin. In this manner, the reaction partners accumulate in the metal droplets, providing the raw material from which nanotubes can be grown. Tremel explains: "In this process, the metal droplets are retained in the form of spheres at the end of the tubes, while the nanotubes grow out of them like hairs from follicles. And thanks to the catalytic effect provided by the metal droplets, it is possible to grow nanotubes even at relatively low temperatures."

Using the new technique, the team has been able to produce perfect nanotubes with diameters in a range of 30 - 40 nm and lengths of 100 - 500 nm consisting of several layers of SnS2.