Nov 4 2014

Scientists at chemist James Tour’s lab at Rice University have discovered a cost-effective method to create flexible films of molybdenum disulfide for hydrogen catalysis and energy storage applications.

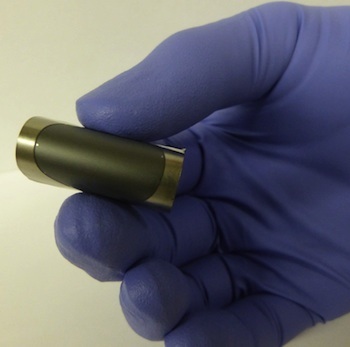

A new material developed at Rice University based on molybdenum disulfide exposes as much of the edge as possible, making it efficient as both a catalyst for hydrogen production and for energy storage. Courtesy of the Tour Group

A new material developed at Rice University based on molybdenum disulfide exposes as much of the edge as possible, making it efficient as both a catalyst for hydrogen production and for energy storage. Courtesy of the Tour Group

Molybdenum disulfide is a 2-D material. The scientists have made nanoporous, flexible films of this material, which is a dichalcogenide. It has flat sides which are inert. However, for hydrogen evolution reaction (HER), their edges act as very efficient catalysts. Fuel cells use the HER process for pulling hydrogen from water. The flexible film form makes fullest use of the exposed edge which could be advantageous for energy-oriented applications.

Graphene is flat, as it is pure carbon. Molybdenum disulfide is made up of both molybdenum and sulfur atoms. Sulfur atoms are in planes on top of and also below a layer of molybdenum. These are revealed as three separate layers when seen from the side. When seen from top they are revealed as ordered hexagon rows. A robust edge is created and this improves storage and catalytic reactions.

2-D materials have very little edge. However the molybdenum disulfide films are highly porous with plenty of edge and 5-6nm planes. Exposure to current makes the film to catalyze hydrogen separation from water. The film performs as good as other molybdenum disulfide structures.

Rice researchers used room-temperature anodization to grow porous molybdenum oxide film on a molybdenum substrate. Then for an hour, at a temperature of 300°C, the film was exposed to sulfur vapor. This enabled conversion of the material into molybdenum disulfide, without the nano-porous sponge-like structure getting damaged.

Supercapacitors can deliver more power than batteries and also have a long lifespan.

They can store energy rapidly and can release the energy in a burst. Rice lab researchers have built supercapacitors using molybdenum disulfide films. During testing, even after 10,000 charge-discharge cycles these supercapacitors retained 90% of their capacity, and after 20,000 cycles they were able to retain 83%.

These molybdenum disulfide films hold promise for batteries, supercapacitors and fuel cells.

The researchers have published this study in Advanced Materials journal.

References