A research team from Rice University has succeeded in developing flexible multilayer graphene sheets, by patterning inexpensive polyimide sheets with a computer-controlled laser.

You buy polyimide flexible plastic sheets in huge rolls, called Kapton, and the process is done entirely in air with a rapid writing process. That sets it up for a very scalable, industrial process.

Professor James Tour

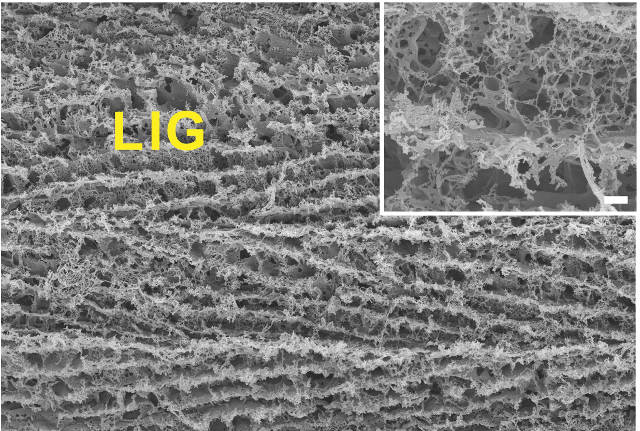

A scanning electron microscope shows a close-up of laser-induced graphene foam produced by researchers at Rice University. Image credit: Tour Group/Rice University

A scanning electron microscope shows a close-up of laser-induced graphene foam produced by researchers at Rice University. Image credit: Tour Group/Rice University

This process does not require any controlled environments or hot furnaces, working perfectly in air at ambient temperature. The plastic sheets used as the base material are very low cost, making the process ideal for industrial applications like energy storage and electronics.

The "laser-induced graphene" made in this process is not quite the same as the pristine 2D sheet we are used to hearing about - it consists of a foam of interconnected graphene flakes that have five-, six- and seven-atom rings in a jumbled structure. In 2D graphene sheets, these would be considered defects, but in this case they are close enough to graphene's pure hexagonal structure to reproduce some of it's famous properties as an electrical conductor.

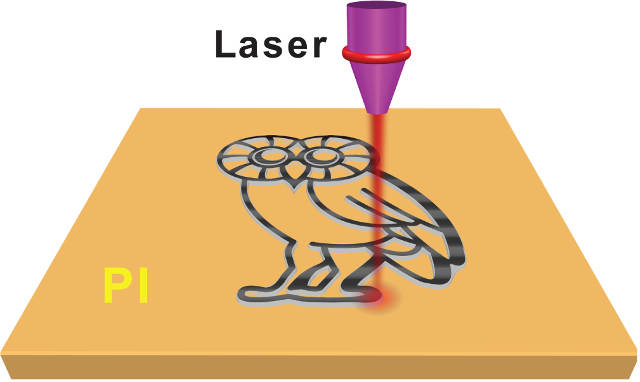

The process was discovered by the James Tour group at Rice University. As a demonstration, the team made millimeter-sized LIG patterns of Rice Owls, the mascot of the school. they were also able to create microscale supercapacitors in one-step scribing for practical testing.

Rice chemist James Tour stated that the one-step process was scalable, and could enable production of nanoscale electronics using a rapid roll-to-roll method. Tour is the professor of materials science and nanoengineering and of computer science, and the T.T. and W.F. Chao Chair in Chemistry.

The fact that highly defective graphene performs so well is a freebie, a gift from nature.

Boris Yakobson

The final product derived from this process is an 20μm-thick porous foam of interconnected flakes. As the laser does not go through all the way, the foam stays fixed to a flexible, insulating and manageable plastic base.

Whilst graphene is famous for its incredible electrical conductivity, this laser-induced version is actually even less conductive than copper. However, Tour is convinced that this won't reduce the attractiveness of the process - high conductivity is not needed for many applications.

Jian Lin, an assistant professor at the University of Missouri and who was a former postdoctoral researcher in Tour’s Group, led a team of researchers to find out suitable polymers for this process. Among 15 polymers that were tried, they found that only two were suitable, with polyimide producing the best results.

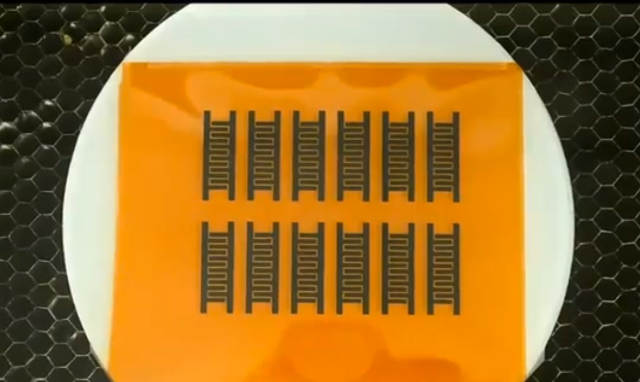

Tour said that LIG could be easily used to makes supercapacitors, which have higher energy-delivering capability than capacitors, but also have their rapid-charging and power capacity. If they can be made affordable, they have the potential to beat lithium ion batteries for electrocni devices, electric cars, and storage of renewable electricity.

A Rice University lab is using a laser to write graphene microsupercapacitors in a common polymer material. The laser removes nearly everything but carbon from a 20-micron layer, leaving behind porous graphene foam that may be suitable for electronics or energy storage. (Credit: Tour Group/Rice University)

The defects in the graphene could be the key, said Tour.

“A normal sheet of graphene is full of six-member rings. Once in a while you see a meandering line of 5-7s, but this new material is filled with 5-7s. It’s a very unusual structure, and these are the domains that trap electrons. Had it just been normal (highly conductive) graphene, it couldn’t store a charge.”

Theoretical physicist Boris Yakobson’s group had performed calculations, which demonstrated that the balanced five-and-seven formations enhanced the metallic property of the material and also improved its ability to store charges.

Yakobson is Rice’s Karl F. Hasselmann Professor of Materials Science and NanoEngineering, a professor of chemistry and a member of the Richard E. Smalley Institute for Nanoscale Science and Technology. He commented:

“Theoretical methods and density functional computations allowed us to look inside the electronic energy states’ organization. What we discovered is that the very low density of available states — which is crucial for the layer capacitance — increases dramatically, due to various topological defects, mainly pentagonal and heptagonal rings."

The existence of the many defects were confirmed using transmission electron microscope imaging by the chairman of the Department of Physics at the University of Texas at San Antonio, Miguel José Yacaman:

“We have what is called aberration-corrected microscopy, which allows us to see the defects. The resolution is below 1 angstrom, basically 70 picometers (trillionths of a meter), and that’s what you need to really look at single atoms.”

Rice’s Oshman Engineering Design Kitchen has machine shop lasers that were used by Tour’s lab to manufacture microsupercapacitors. These capacitors demonstrated capacitance that was comparable to that of other microsupercapacitors that are based on carbon.

The new microsupercapacitors demonstrated 9mW/cm2 power density and over 4mF/cm2 of capacitance. Even after 9,000 charge/discharge cycles negligible degradation was observed. Tour said that this capacitance was sufficient for producing low-cost wearable electronic devices. His group is continuing efforts to improve this material.

Graphene microsupercapacitors were created in polymer with a laser at Rice University’s Oshman Engineering Design Kitchen. The room-temperature process makes graphene that may be suitable for electronics or energy storage. (Credit: Tour Group/Rice University)

Tour said the lab didn’t start out looking for LIG.

“Everything converged. Nature can be a hard taskmaster, but once in a while, she gives you something much better than what you had asked for. Or expected.”

Zhiwei Peng, Errol Samuel, Ruquan Ye and Yuanyue Liu, who are graduate students at Rice, are co-authors of this study along with researcher Francisco Ruiz-Zepeda from the University of Texas at San Antonio.

This research has received support from The Air Force Office of Scientific Research and its Multidisciplinary University Research Initiative (MURI), the National Center for Research Resources, the National Institute on Minority Health and Health Disparities, the Office of Naval Research MURI, and the National Science Foundation Partnerships for Research and Education in Materials.

This study has been published online in Nature Communications journal by the labs of Tour and Yakobson.

Sources and Further Reading

Defects are perfect in laser induced graphene - Rice University News