Mar 10 2015

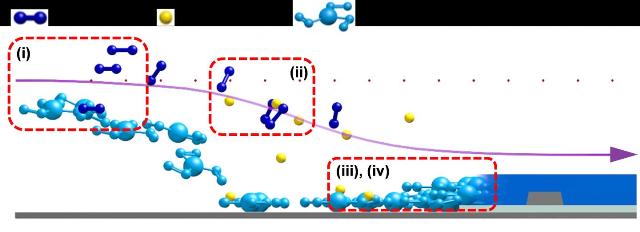

This is a schematic image to show how the initiated chemical vapor deposition (iCVD) technique produces pV3D3 polymeric films: (i) introduction of vaporized monomers and initiators, (ii) activation of initiators to thermally dissociate into radicals, (iii) adsorption of monomers and initiator radicals onto a substrate, and (iv) transformation of free-radical polymerization into pV3D3 thin films. Credit: KAIST

This is a schematic image to show how the initiated chemical vapor deposition (iCVD) technique produces pV3D3 polymeric films: (i) introduction of vaporized monomers and initiators, (ii) activation of initiators to thermally dissociate into radicals, (iii) adsorption of monomers and initiator radicals onto a substrate, and (iv) transformation of free-radical polymerization into pV3D3 thin films. Credit: KAIST

Researchers at the Korea Advanced Institute of Science and Technology (KAIST) have developed ultrathin polymer insulators which play an important role in field-effect transistors (FETs) or low-power soft electronics.

The team used an initiated chemical vapor deposition technique to create the ultrathin polymeric insulating layer for building transistors which are flexible and also consume low amounts of power. The team used vaporized monomers for forming polymeric films, which were grown on various surfaces conformally.

In any modern electronic device, FETs play a critical role. They are commonly used in many devices, which include flat-panel displays, computers and cell phones. FETs are made up of a semiconductor channel layer and an insulating layer when they are used along with gate, source, and drain electrodes.

In FETs, the insulator plays a critical role in control of the semiconductor channel’s conductance, which is linked to the current flow that occurs within the translators. Ultrathin, electrically robust insulators are necessary for consistent, low-power operation of FETs.

Typically, inorganic materials are used for making such insulators, and they are constructed on glass, silicon or other such hard surfaces. This is due to the exceptional reliability and performance.

These insulators are rigid and a high process temperature is required. This makes them difficult for implementation into soft electronics. Recently, many studies have been performed on polymers as promising insulating materials that demonstrate compatibility with newly developed semiconductor materials and soft unconventional substrates.

The conventional techniques that have been used so far for developing polymer insulators, were constrained by the low surface coverage at very low thickness. This affected adoption of polymeric insulators for FETs from low voltage operations.

Professor Sung Gap Im of the Chemical and Biomolecular Engineering Department at KAIST, and Professor Seunghyup Yoo and Professor Byung Jin Cho of the Electrical Engineering Department, together developed "pV3D3," which was an insulating layer of organic polymers that could be scaled down to a great extent without affecting its ideal insulating properties. They used the "initiated chemical vapor deposition” (iCVD) method which is an all-dry vapor-phase technique for scaling down to a thickness that was less than 10nm.

Gaseous monomers and initiators are allowed to react by the iCVD process with each other. This takes place in a low vacuum condition, and hence conformal polymeric films having very good insulating properties get deposited on a substrate material. iCVD has a surface-growing character that can help address the issues related to surface tension and can help produce pure, ultrathin polymeric films with high uniformity.

This can take place over a large area without being limited by the substrate or the surface. Additionally, most iCVD polymers can be produced at room temperature which reduces the damage that occurs to the substrates at room temperature and the strain that is exerted.

The research team used the pV3D3 insulator and created high-performance, low-power FETs that were dependent upon different semiconductor materials including, graphene, oxides and organics. This demonstrated the wide compatibility of the pV3D3 insulator.

The team also produced a stick-on, which is an electronic component that can be removed using common packaging tape as a substrate. The research team collaborated with Professor Yong-Young Noh from Dongguk University in Korea and built a transistor array on a flexible substrate having the pV3D3 insulator.

The down-scalability and wide range of compatibility observed with iCVD-grown pV3D3 are unprecedented for polymeric insulators. Our iCVD pV3D3 polymeric films showed an insulating performance comparable to that of inorganic insulating layers, even when their thickness were scaled down to sub-10 nm. We expect our development will greatly benefit flexible or soft electronics, which will play a key role in the success of emerging electronic devices such as wearable computers.

Professor Im

The researchers have published the results of their study titled "Synthesis of ultrathin polymer insulating layers by initiated chemical vapor deposition for low-power soft electronics" in Nature Materials.